Table of Contents

Ask Us Any Question

Why Compare MgSO4 and MgCl2 Boards

In modern construction, choosing the right materials is crucial not only for structural integrity but also for long-term safety and durability. Magnesium-based boards, commonly referred to as magnesium oxide boards or MgO boards, have gained significant attention in the building industry for their excellent fire resistance, moisture tolerance, and eco-friendly properties. Among these, two main types dominate the market: MgSO4 board (magnesium sulfate board) and MgCl2 board (magnesium chloride board).

At first glance, both boards may appear similar, as they share a common core of magnesium oxide and similar construction processes. However, subtle differences in their composition and treatment can impact their performance in real-world applications. Builders, architects, and distributors often face the question: which one performs better? This comparison is especially important in projects where moisture exposure, corrosion risks, or material compatibility are critical considerations.

Understanding these differences is not just an academic exercise. It affects decisions on wall panels, sub-flooring, ceilings, and other critical components. Incorrect choices can lead to issues like board delamination, sweating, or reduced durability under challenging environmental conditions. By exploring the characteristics of MgSO4 board and MgCl2 board, this article aims to provide clear guidance for professionals seeking reliable, high-performance magnesium boards.

In the following sections, we will delve deeper into the properties of each board, their production processes, key differences, and practical performance, ensuring readers can make informed decisions based on both technical data and real-world experience.

What Is MgSO4 Board?

MgSO4 board, also known as magnesium sulfate board, is a specialized type of magnesium oxide board that has become increasingly popular for construction projects requiring high durability, fire resistance, and moisture tolerance. Its core composition typically includes magnesium oxide (MgO), magnesium sulfate (MgSO4), and reinforcing fillers such as perlite, which improve structural stability and thermal insulation properties. Unlike MgCl2 board, MgSO4 board does not contain chloride ions, making it inherently more stable and less prone to corrosion issues when in contact with metals.

The production process of MgSO4 board is straightforward yet precise. Raw materials are carefully mixed and combined with water to form a slurry, which is then pressed and cured under controlled conditions. The curing process allows the chemical reactions to complete, resulting in a rigid, dense, and uniform board. This method ensures that the board maintains consistent strength while retaining its fireproof and moisture-resistant properties.

One of the key advantages of MgSO4 board is its chloride-free nature, which eliminates the risk of steel reinforcement corrosion or staining that sometimes occurs with MgCl2 boards. This property makes MgSO4 board particularly suitable for interior walls, ceilings, and areas where metal fasteners are frequently used. In addition, its lightweight composition facilitates easier handling and installation without compromising durability.

From an environmental perspective, MgSO4 board is highly sustainable. It can be manufactured with low-energy inputs, utilizes industrial by-products, and does not release harmful gases during installation or in the event of a fire. These features make it an attractive option for builders and architects pursuing eco-friendly construction practices.

In summary, MgSO4 board stands out for its stability, fire resistance, moisture tolerance, and environmental friendliness. Its consistent quality and reliability make it a top choice for projects that demand long-lasting performance, especially in environments where corrosion or water exposure is a concern.

What Is MgCl2 Board?

MgCl2 board, or magnesium chloride board, is another widely used type of magnesium oxide board. Its main ingredients include magnesium oxide (MgO), magnesium chloride (MgCl2), and various fillers like perlite or wood fibers to enhance strength and workability. While it shares a similar production process with MgSO4 board, the presence of chloride ions introduces unique considerations in terms of stability and long-term performance.

A distinguishing feature of MgCl2 board is the soaking process, which is applied to remove excess chloride ions from the board before it reaches the market. This step is crucial because leftover chlorides can cause issues such as “sweating” or “crying boards”, where moisture collects on the board surface, potentially leading to corrosion of metal fasteners or unsightly staining. The soaking process involves immersing the board in water for a specific period, followed by careful drying, which ensures that chloride levels are minimized without compromising the board’s structural integrity.

Despite this extra processing step, MgCl2 board retains many of the desirable properties of magnesium oxide boards. It is fire-resistant, relatively lightweight, and easy to install. It performs well in standard interior environments and is often more cost-effective than MgSO4 board, making it a popular choice for budget-conscious projects.

However, it is important to note that MgCl2 board is generally less compatible with metal components in humid or coastal environments due to its chloride content, even after soaking. This is a key factor that differentiates it from MgSO4 board, which is naturally chloride-free and thus inherently safer in such conditions.

In practice, many manufacturers, including Suparna, apply the soaking technique to guarantee product stability and prevent common issues associated with chloride-rich boards.

In summary, MgCl2 board offers reliable fire resistance and workability, but it requires additional treatment to address chloride-related risks. Understanding this distinction is essential for builders and architects when choosing the right magnesium oxide board for their projects.

5 Key Differences Between MgSO4 Board and MgCl2 Board

While MgSO4 board and MgCl2 board share a similar base composition and production process, there are several practical differences that can impact performance in real-world applications. Understanding these differences helps builders and architects select the most suitable board for specific project needs.

1. Moisture Resistance

MgSO4 board naturally exhibits superior moisture resistance due to its chloride-free composition. In humid or high-moisture environments, it is less likely to absorb water or warp over time. On the other hand, MgCl2 board contains chloride ions that can attract moisture, making the soaking process essential to mitigate risks like surface sweating. Even after soaking, MgCl2 board remains more sensitive to prolonged exposure to humidity compared with MgSO4 board.

2. Chloride Content and Corrosion Risk

Chloride ions in MgCl2 board can corrode metal fasteners or structural components if not properly treated. The soaking process reduces chloride content, but caution is still required for installations involving steel or aluminum. MgSO4 board contains no chloride ions, eliminating corrosion risks entirely, which makes it ideal for metal-framed constructions or areas with exposed metal fittings.

3. Compatibility with Finishing Materials

Both boards can accept paints, plaster, and decorative coatings. However, MgSO4 board tends to be more compatible with sensitive materials like PVC films, laminates, or adhesives because it does not release chlorides that can react with coatings. MgCl2 board, especially if improperly treated, may occasionally cause minor staining or adhesion issues over time.

4. Long-Term Durability and Maintenance

Over the lifespan of a building, MgSO4 board generally requires less maintenance due to its stability under fluctuating humidity and temperature. MgCl2 board can perform well initially, but the need for careful handling and potential sensitivity to moisture can lead to higher maintenance or replacement considerations in challenging environments.

5. Environmental Impact and Cost Considerations

MgSO4 board is often considered more environmentally friendly because it avoids chloride-related issues that may lead to structural repairs or additional chemical treatments. MgCl2 board may be slightly less expensive upfront, and its production is similar to MgSO4 board, but the additional soaking step adds a small operational cost. Evaluating both price and lifecycle considerations is important when making procurement decisions.

Performance Comparison in Real Applications

Understanding how MgSO4 board and MgCl2 board perform in actual construction projects is crucial for making informed decisions. Laboratory data provides a controlled perspective, but real-world conditions—such as humidity, temperature fluctuations, and contact with metal—can reveal subtle yet important differences.

Humidity and Coastal Environments

In high-humidity areas or coastal regions, MgSO4 board clearly outperforms MgCl2 board. Its chloride-free nature prevents the risk of corrosion or staining on adjoining metal components, such as screws, brackets, or framing. Builders have reported that walls and ceilings made from MgSO4 board remain dimensionally stable even in coastal climates with high salt content in the air.

MgCl2 board, although treated via the soaking process, still requires careful installation in such environments. Prolonged exposure to moisture can lead to minor surface sweating, and while this rarely compromises structural integrity if properly managed, it may necessitate additional maintenance over time.

Fire Safety Performance

Both boards offer excellent fire resistance due to the inherent properties of magnesium oxide. In tests simulating fire exposure, MgSO4 board and MgCl2 board can withstand high temperatures without rapid degradation or structural collapse. For builders, this makes either option suitable for interior walls, ceilings, and subflooring where fire safety is a priority.

Since fire resistance is similar, the main differentiator in performance becomes environmental stability, particularly moisture management and corrosion risk, rather than thermal performance.

Installation and Handling

On construction sites, both boards are lightweight and relatively easy to cut, shape, and fix using standard tools. MgSO4 board is slightly more forgiving, as it is less sensitive to water during installation. MgCl2 board requires careful handling to avoid pre-soaked areas being exposed to excess moisture, which could temporarily affect surface finish or workability.

Builder Feedback

Experienced contractors often favor MgSO4 board for projects that involve high humidity, metal integration, or long-term durability requirements. MgCl2 board remains popular for standard interior projects, where cost considerations and availability are prioritized. Many reports highlight that with proper soaking treatment, MgCl2 board performs reliably, but MgSO4 board reduces risk and simplifies maintenance, which is why it is increasingly preferred in premium or demanding projects.

Common Misunderstandings About MgO, MgSO4, and MgCl2 Boards

Despite the growing popularity of magnesium-based boards, there remains some confusion in the construction market regarding terminology and product classification. One of the most common misunderstandings revolves around the term “MgO board”.

Many people assume that MgO board specifically refers to MgSO4 board or MgCl2 board, when in fact it is a general term encompassing both types. In other words, MgO board is the full name for boards primarily made of magnesium oxide, and it can include either the sulfate-based or chloride-based variants depending on the manufacturing process and raw materials used.

Another frequent misconception is regarding performance differences. Some contractors believe that all MgO boards are identical in moisture resistance, fire safety, and durability. While the fire resistance is indeed similar, moisture handling and chloride content are key differentiators. MgSO4 board is inherently chloride-free, which eliminates the risk of corrosion, while MgCl2 board requires additional processing—specifically the soaking process—to mitigate chloride-related issues.

There is also confusion about compatibility with finishing materials. Some users think that any MgO board will automatically accept paints, laminates, or PVC films without issue. In reality, MgSO4 board offers higher compatibility, particularly with sensitive coatings, due to its lack of residual chlorides, whereas improperly treated MgCl2 board may occasionally cause minor staining or adhesion problems.

Finally, pricing and environmental assumptions often lead to misunderstandings. MgCl2 board may appear cheaper upfront, but the additional soaking process and potential maintenance needs can offset the initial cost advantage over time. MgSO4 board, though slightly higher in initial price in some markets, offers long-term stability, lower maintenance, and reduced risk, which many builders consider a worthwhile investment.

By clarifying these points, construction professionals can make informed decisions and avoid costly mistakes. Correctly identifying the type of MgO board and understanding its properties ensures the right choice for every project, from interior walls and ceilings to subflooring and specialty applications.

Conclusion — Which One Performs Better?

After examining the properties, production processes, and real-world performance of MgSO4 board and MgCl2 board, it becomes clear that both magnesium-based boards have their place in construction projects. Each type offers fire resistance, ease of installation, and overall durability. However, the choice ultimately depends on the specific environmental conditions and long-term maintenance considerations.

MgSO4 board stands out for projects where moisture management and corrosion prevention are critical. Its chloride-free composition eliminates the risks associated with metal corrosion, making it ideal for coastal environments, high-humidity areas, or applications where metal fasteners and fittings are frequently used. The board’s stability, compatibility with coatings, and minimal maintenance requirements make it a reliable choice for long-term performance.

MgCl2 board, on the other hand, is a cost-effective option for standard interior applications. When properly treated with the soaking process to remove excess chloride ions, it performs reliably in normal indoor environments. Builders using MgCl2 board should ensure correct installation and occasional monitoring in high-moisture situations to prevent issues such as surface sweating.

| Feature | MgSO4 Board | MgCl2 Board |

|---|---|---|

| Chloride Content | None | Low (after soaking) |

| Moisture Resistance | High | Moderate |

| Corrosion Risk | None | Low to Moderate |

| Compatibility with Finishes | Excellent | Good |

| Maintenance | Low | Moderate |

| Cost | Moderate | Lower upfront |

In summary, if your priority is long-term durability, minimal maintenance, and chloride-free assurance, MgSO4 board generally performs better and offers peace of mind for builders and end-users. MgCl2 board remains a viable choice for budget-conscious projects with controlled environmental conditions.

For those interested in exploring high-quality magnesium boards, Suparna applies advanced techniques like the soaking process to ensure stability and prevent chloride-related issues. To learn more about our products or request samples, feel free to contact our team.

Explore the best heat proof and heat resistant materials for safer construction. Learn their benefits, applications, and safety advantages.

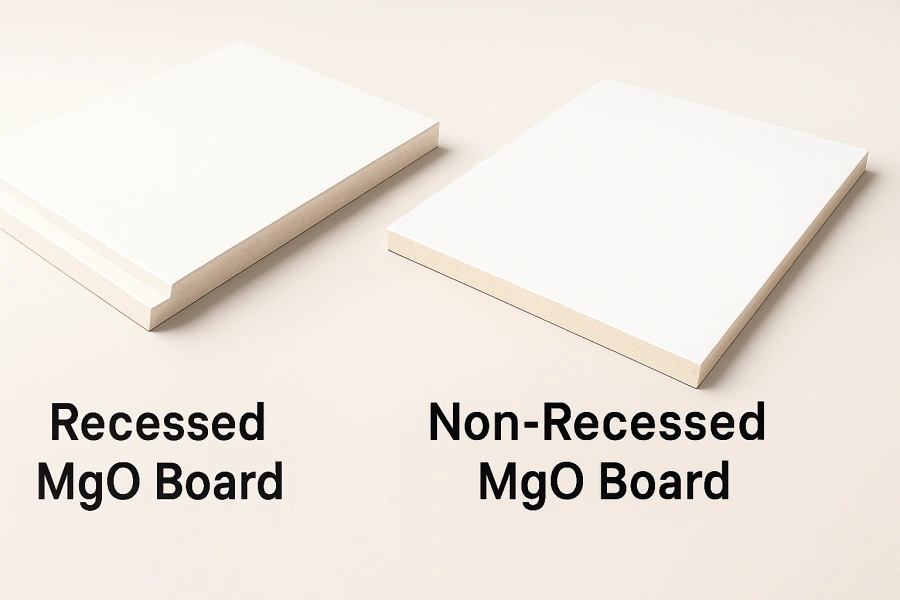

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Discover the top 4 fire rated subfloor materials with pros and cons. Learn which subfloor offers the best fire resistance, durability, and long-term value.