Table of Contents

Ask Us Any Question

1. Why Passive Fire Protection Matters

In modern construction, fire safety has become one of the most important considerations for architects, engineers, and building owners. Every year, fires cause severe damage to properties and put human lives at risk. While fire alarms and sprinkler systems are often the first things people think of when it comes to fire safety, the truth is that these active systems are only one part of an effective fire protection strategy. Buildings also rely heavily on materials and structures that can passively resist fire and heat—this is where passive fire protection comes into play.

Passive fire protection, or PFP, is not about stopping a fire before it starts. Instead, it is about giving people time—time to escape safely and time for emergency responders to take action. By slowing down the spread of flames and maintaining the structural integrity of a building, passive fire protection can make the difference between a contained incident and a catastrophic loss.

In the construction industry, materials that resist fire, smoke, and heat are essential for ensuring safety and compliance with international building codes. These materials do not need electricity or manual operation; they work automatically when exposed to high temperatures. From fire-resistant walls and floors to insulation and coatings, passive fire protection plays a vital role in every modern building.

To understand how it works and why it is indispensable, let’s take a closer look at the science and materials behind passive fire protection.

2. Understanding Passive Fire Protection (PFP)

Passive fire protection refers to systems and materials that are designed to prevent the spread of fire and smoke without requiring human intervention or mechanical operation. Unlike active fire protection, which relies on alarms, sprinklers, and other detection or suppression mechanisms, passive systems act automatically when exposed to heat, forming barriers that protect the structure and its occupants.

2.1 Definition and Core Function

At its core, passive fire protection aims to contain a fire within a limited area, slow down the transfer of heat, and maintain the structural stability of a building for a specified period. The primary goal is not to extinguish the fire but to provide time for evacuation and emergency response. Materials used in passive fire protection often have high melting points, low thermal conductivity, and the ability to resist combustion for extended periods.

2.2 How PFP Works

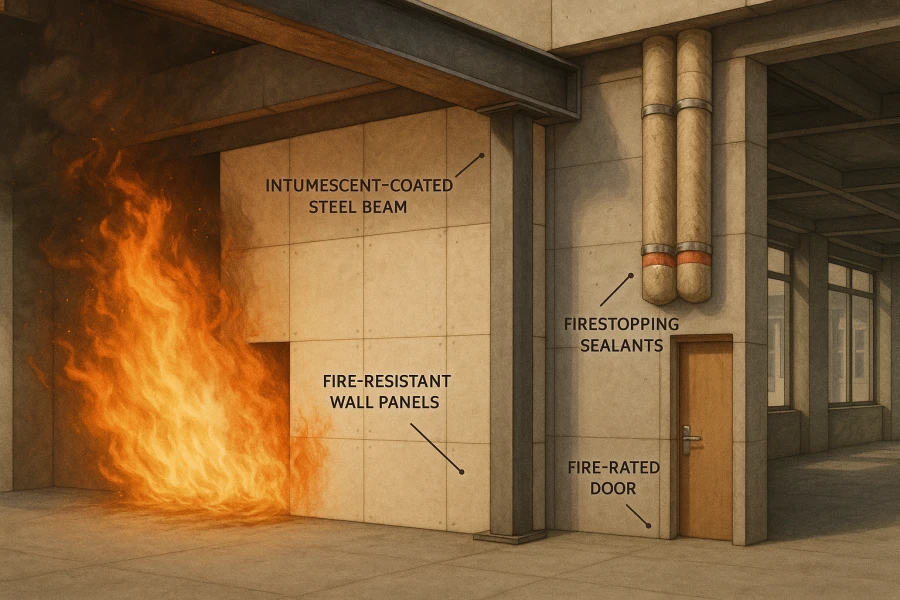

Passive fire protection works by creating physical barriers between fire sources and vulnerable areas. For example, fire-resistant walls can compartmentalize spaces, preventing flames from spreading from one room to another. Fireproof insulation reduces heat transfer to structural steel, preventing deformation or collapse. Even coatings like intumescent paints expand under heat to form a protective char layer that shields the underlying materials. By slowing down fire progression, PFP minimizes damage and reduces risks to human life.

2.3 Difference Between Active and Passive Fire Protection

While passive fire protection relies on materials and design to resist fire, active fire protection depends on mechanical or human-triggered systems. Common examples of active systems include smoke detectors, fire alarms, and sprinkler systems. Both types are complementary: active systems can detect and suppress fires early, while passive systems contain fire spread and protect structural integrity. A well-designed building integrates both strategies to maximize safety.

2.4 Common Applications

Passive fire protection is implemented in multiple areas of a building. Walls and ceilings are often constructed with fire-resistant boards or panels. Structural steel may be coated with intumescent paints or protected with insulation. Openings for pipes, cables, and ducts are sealed with firestopping materials. Even doors and windows can be designed with fire-resistant properties to prevent the spread of smoke and flames. Each element works together to form a comprehensive safety net that protects both people and property.

3. Five Effective Materials for Passive Fire Protection

Choosing the right materials is critical for effective passive fire protection. Different materials serve different purposes, from structural protection to fire containment in openings. Here are five of the most effective materials widely used in modern construction.

3.1 Fire-Resistant Boards (e.g., Magnesium Oxide Board, Gypsum Board)

Fire-resistant boards are one of the most common passive fire protection materials. They are widely used in walls, ceilings, and subfloor systems. Magnesium oxide (MgO) boards, gypsum boards, and calcium silicate boards are typical examples.

Magnesium oxide boards are highly fire-resistant, capable of withstanding extreme temperatures for prolonged periods. They are also moisture-resistant, lightweight, and environmentally friendly, making them a popular choice in both residential and commercial buildings. Gypsum boards offer good fire resistance at a lower cost, though they may be less durable in high-moisture areas. Calcium silicate boards provide high thermal stability and are often used in industrial settings.

These boards function by acting as physical barriers that slow the spread of fire and heat, protecting both occupants and the building’s structural elements. Their installation is straightforward, making them a practical option for passive fire protection in various applications.

3.2 Intumescent Coatings

Intumescent coatings are specialized paints or varnishes that expand when exposed to high temperatures, forming an insulating char layer. This layer protects the underlying material, such as steel or timber, from heat and flame, delaying structural failure.

Intumescent coatings are especially effective for protecting steel structures, which can lose strength quickly when exposed to fire. The coatings are applied like paint and do not significantly alter the appearance of the structure, making them suitable for visible architectural elements. Regular inspection and maintenance are necessary to ensure continued effectiveness over time.

3.3 Firestopping Materials

Firestopping materials are used to seal openings and penetrations in walls, floors, and ceilings. Common areas include gaps around pipes, cables, ducts, and conduits. These materials prevent fire and smoke from spreading through these openings, maintaining compartmentalization in the building.

Examples of firestopping materials include fire-rated sealants, firestop putties, fire collars, and intumescent wraps. Proper installation is critical, as any gaps or improper seals can compromise the effectiveness of the passive fire protection system. Firestopping ensures that even when fire occurs, its spread is slowed, giving occupants more time to evacuate safely.

3.4 Fire-Resistant Doors and Glazing

Doors and windows can also play a significant role in passive fire protection. Fire-rated doors are designed to withstand heat and flames for a specified period, preventing fire from spreading between rooms or floors. Similarly, fire-resistant glass can maintain its integrity under high temperatures, allowing visibility while blocking flames and smoke.

These materials are especially important in evacuation routes, stairwells, and areas that must remain accessible during a fire. Compliance with standards such as BS 476, UL 10C, and EN 1634 ensures that these doors and glazing provide reliable protection in emergency situations.

3.5 Fireproof Insulation Materials

Fireproof insulation materials serve a dual purpose: reducing heat transfer and resisting combustion. Rock wool, ceramic fiber, and glass wool are common examples. These materials are used in walls, ceilings, roofs, and HVAC systems to protect structural components and reduce the risk of fire spreading.

Rock wool, made from natural stone, offers excellent thermal resistance and does not burn easily. Ceramic fiber can withstand extremely high temperatures and is often used in industrial applications. Glass wool provides fire resistance while also offering sound insulation benefits. By combining insulation with fireproof properties, these materials enhance both safety and energy efficiency in modern buildings.

4. Testing Standards and Fire Ratings

For passive fire protection materials to be effective and reliable, they must meet established testing standards. These standards ensure that materials perform as expected under real fire conditions and comply with building regulations.

4.1 Overview of International Standards

Various countries and regions have developed fire testing standards to evaluate the performance of passive fire protection materials. Common standards include:

-

EN (European Norms): EN 13501 and related parts classify materials based on fire resistance, reaction to fire, and smoke production.

-

ASTM (American Society for Testing and Materials): Standards like ASTM E119 measure fire resistance of building elements such as walls, floors, and doors.

-

UL (Underwriters Laboratories): UL 10C and UL 263 provide testing protocols for doors, windows, and structural components.

-

ISO (International Organization for Standardization): ISO 834 and ISO 9705 focus on fire resistance and reaction to fire in building materials.

Compliance with these standards ensures that the materials will perform predictably during a fire, providing essential protection for both occupants and structures.

4.2 Fire Resistance Ratings

Fire resistance ratings indicate how long a material or assembly can withstand fire exposure without failing. Ratings are typically expressed in minutes or hours, such as 30, 60, 90, or 120 minutes. A 60-minute rating, for example, means the material can resist fire for one hour under standardized test conditions.

These ratings are crucial for building design, as different applications require different levels of protection. For instance, a structural steel beam may need a higher rating than an internal partition wall, while escape routes like stairwells must maintain integrity for the duration of evacuation.

4.3 Importance of Certified Testing

Certified testing not only ensures safety but also guarantees compliance with local building codes. Using materials that are untested or uncertified can compromise the entire passive fire protection strategy, potentially endangering lives and leading to legal consequences. Therefore, architects and builders should always prioritize certified and tested materials when designing fire-resistant structures.

5. Benefits of Using Passive Fire Protection Materials

Implementing passive fire protection materials in a building offers multiple advantages that extend beyond just compliance with safety regulations. These benefits make PFP an essential consideration in both new construction and renovation projects.

5.1 Enhanced Safety for Occupants

The primary benefit of passive fire protection is the protection of human life. By slowing the spread of fire and smoke, PFP materials give occupants more time to evacuate safely. Fire-resistant walls, doors, and partitions compartmentalize a building, reducing the risk of fire reaching escape routes and emergency exits. This delay can be crucial in saving lives during a fire emergency.

5.2 Structural Stability During Fire

Passive fire protection helps maintain the integrity of a building’s structure under high temperatures. Steel beams and columns, for example, can weaken rapidly in a fire, potentially leading to partial or complete structural collapse. Materials like intumescent coatings and fireproof insulation shield these elements, ensuring that the building remains stable long enough for evacuation and firefighting efforts.

5.3 Reduced Repair and Replacement Costs

Buildings that incorporate effective passive fire protection often suffer less damage during a fire incident. Fire-resistant boards and coatings prevent flames from spreading, which can reduce the extent of destruction and lower repair costs. Investing in PFP materials is a proactive way to minimize long-term financial risks associated with fire damage.

5.4 Compliance with Building Codes and Standards

Most countries require buildings to meet certain fire safety standards. Using certified passive fire protection materials ensures compliance with local and international building codes, helping architects, builders, and property owners avoid fines or legal issues. Additionally, meeting these standards can improve the market value and insurance rating of the property.

5.5 Eco-Friendly and Sustainable Options

Many modern PFP materials, such as magnesium oxide boards and rock wool insulation, are environmentally friendly. They contain minimal harmful chemicals, are often recyclable, and contribute to sustainable building practices. Using these materials aligns with green building initiatives while also enhancing safety.

6. Choosing the Right Passive Fire Protection Solution

Selecting the most suitable passive fire protection materials requires careful consideration of several factors, including building type, risk exposure, budget, and maintenance requirements. Making informed decisions ensures both safety and cost-effectiveness.

6.1 Assessing Building Requirements

Different buildings have different fire protection needs. Residential buildings may prioritize compartmentalization with fire-resistant walls and doors, while industrial facilities might require high-temperature insulation for structural steel and fireproof coatings for machinery areas. Architects and engineers should evaluate the building’s layout, occupancy, and fire load to determine the appropriate combination of materials.

6.2 Material Selection and Compatibility

Not all PFP materials are suitable for every application. Fire-resistant boards, insulation, intumescent coatings, and firestopping materials serve distinct functions. Ensuring compatibility between these materials is crucial. For instance, using a fireproof board in combination with proper firestopping sealants and coatings can create a comprehensive barrier that maximizes protection. In contrast, ignoring compatibility may compromise the effectiveness of the passive fire protection system.

6.3 Budget and Maintenance Considerations

While passive fire protection materials vary in cost, investing in high-quality, durable materials is often more economical in the long run. Fire-resistant boards and coatings with longer lifespans require less frequent replacement or maintenance. Additionally, some materials may need periodic inspection, such as intumescent coatings or firestopping sealants, to ensure ongoing effectiveness. Balancing cost with performance is key to a sustainable PFP strategy.

6.4 Professional Consultation and Installation

Proper installation is critical for passive fire protection to function as intended. Incorrectly installed firestopping materials or improperly applied coatings can significantly reduce the effectiveness of a fire protection system. Consulting with fire safety experts or certified installers ensures that all components are correctly applied and tested according to relevant standards.

6.5 Combining Multiple Materials

For optimal protection, buildings often use a combination of PFP materials. Fire-resistant boards can protect walls and ceilings, intumescent coatings can safeguard steel structures, and firestopping materials can seal penetrations. Using multiple layers of protection provides redundancy and ensures that the building remains safer during a fire incident.

7. Building Safer Futures with Passive Fire Protection

Passive fire protection plays a vital role in modern building safety. By using materials that resist fire, slow heat transfer, and maintain structural integrity, PFP gives occupants crucial time to evacuate and reduces the risk of catastrophic damage. From fire-resistant boards and intumescent coatings to firestopping materials, doors, glazing, and insulation, each component contributes to a comprehensive safety system that protects both people and property.

Integrating passive fire protection into building design is not only about compliance with fire safety regulations; it is an investment in long-term safety, sustainability, and peace of mind. Choosing the right materials and ensuring proper installation can dramatically improve a building’s resilience in the face of fire, while also lowering repair costs and enhancing overall durability.

For those looking to implement or upgrade passive fire protection in their projects, working with experienced suppliers and consulting with fire safety experts is essential. If you are considering safe, sustainable, and high-quality solutions, Suparna offers a range of certified fire-resistant materials, including magnesium oxide boards and advanced coatings, tailored to meet diverse building needs. Contact us today to explore how our products can help safeguard your projects and ensure compliance with modern fire safety standards.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

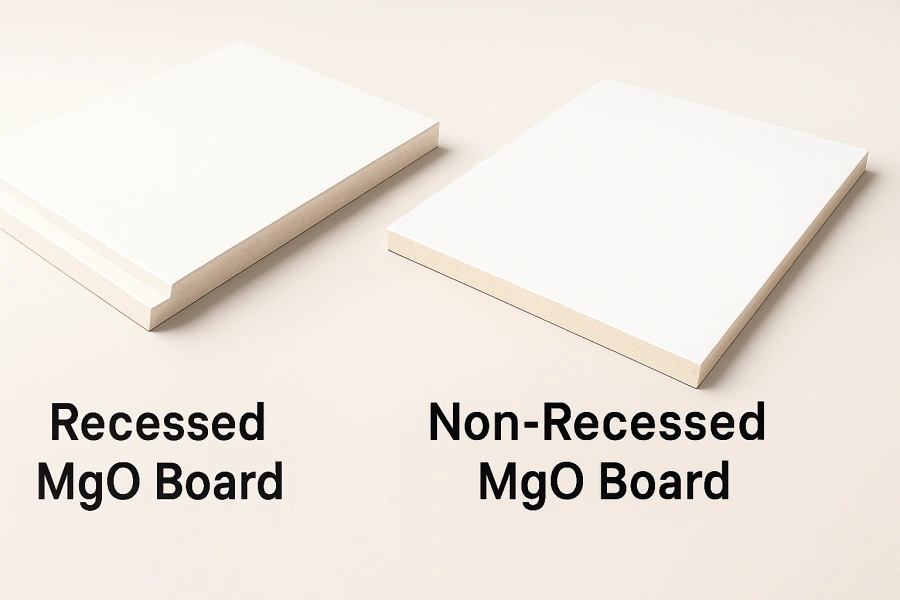

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Discover what magnesium oxide (MgO) is, its key properties, applications, and where to buy high-quality MgO.