Table of Contents

Ask Us Any Question

1. Introduction

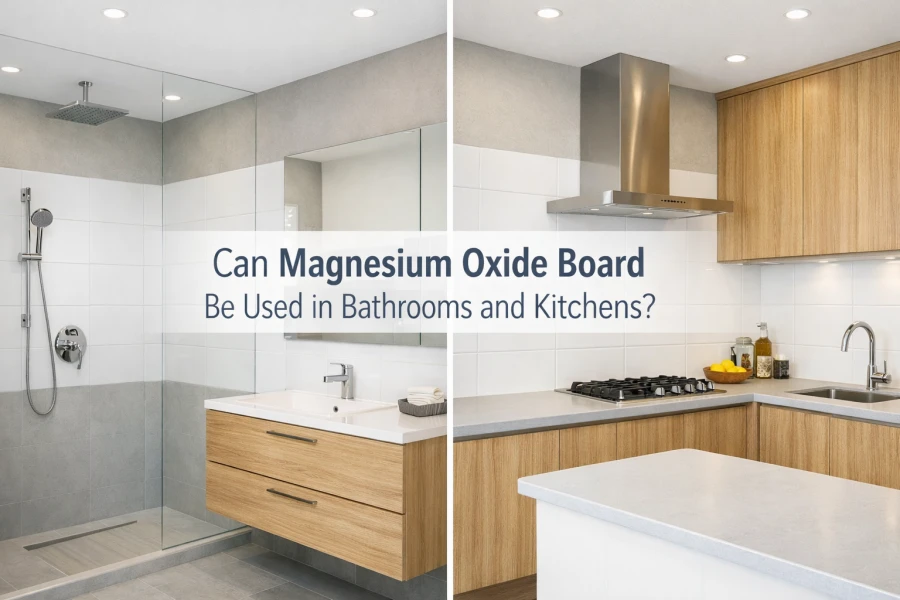

Bathrooms and kitchens are among the most demanding areas in any building when it comes to material selection. These spaces are constantly exposed to moisture, water splashes, steam, temperature fluctuations, and in the case of kitchens, an increased risk of fire. As a result, boards used in these environments must offer more than basic structural performance — they must maintain stability under high humidity, resist mold growth, and meet relevant fire safety expectations.

Traditionally, materials such as gypsum board, cement board, or moisture-resistant plywood have been used in bathrooms and kitchens. However, each of these solutions comes with limitations. Standard gypsum board is highly sensitive to water, cement board can be heavy and difficult to handle, and wood-based panels may swell or degrade over time in humid conditions. These challenges have led designers, contractors, and specifiers to explore alternative boards with improved durability and safety performance.

Magnesium oxide board, often referred to as MgO board, has gained increasing attention in recent years as a high-performance construction panel. Known for its non-combustible nature, dimensional stability, and resistance to biological degradation, MgO board is widely used in fire-rated wall systems, flooring substrates, and prefabricated building components. This naturally raises an important question for interior applications: can magnesium oxide board be reliably used in bathrooms and kitchens?

This article examines the suitability of magnesium oxide board for bathroom and kitchen environments by focusing on key performance factors such as moisture resistance, mold behavior, fire safety, and practical installation considerations. By understanding both its advantages and limitations, builders and project planners can make informed decisions about when and how MgO board should be used in wet and semi-wet areas.

2. What Is Magnesium Oxide Board?

Magnesium oxide board, commonly known as MgO board, is an inorganic construction panel primarily made from magnesium oxide combined with mineral fillers, reinforcing fibers, and additives. Unlike traditional gypsum or wood-based boards, MgO board does not rely on paper facings or organic components for its structural integrity, which significantly influences its performance in challenging environments.

The core of MgO board is formed through a chemical bonding process that results in a dense, stable, and non-combustible matrix. This composition gives the board several inherent properties, including high fire resistance, resistance to insects and mold, and good dimensional stability. Depending on the formulation, MgO boards may be produced using different binding systems, most commonly magnesium chloride or magnesium sulfate.

Compared with conventional gypsum board, MgO board offers superior fire performance and is far less susceptible to softening or disintegration when exposed to elevated temperatures. In contrast to cement board, MgO board is generally lighter in weight and easier to cut and install, which can reduce labor intensity on site. These characteristics have made MgO board a popular choice for fire-rated walls, ceilings, flooring underlayment, and prefabricated building systems.

Another key aspect of magnesium oxide board is its versatility in surface finishing. MgO boards can be tiled, painted, or laminated when properly prepared, making them suitable for a wide range of interior applications. This flexibility is particularly relevant for bathrooms and kitchens, where boards are often covered with ceramic tiles, waterproof coatings, or decorative finishes rather than left exposed.

However, it is important to note that not all MgO boards perform identically. The formulation, manufacturing process, and quality control standards play a critical role in determining moisture behavior, long-term durability, and compatibility with surrounding materials. Understanding these differences is essential when evaluating whether magnesium oxide board is appropriate for use in wet or high-humidity areas such as bathrooms and kitchens.

3. Moisture Resistance of Magnesium Oxide Board

One of the most critical considerations when using any board in bathrooms or kitchens is how it behaves in high-humidity environments. Moisture can cause warping, swelling, delamination, and even mold growth in many common construction panels. Magnesium oxide board, however, exhibits several properties that make it well-suited for wet or semi-wet areas, provided the right type and installation methods are chosen.

3.1 How MgO Board Performs in High-Humidity Environments

MgO boards are inherently more dimensionally stable than gypsum boards in the presence of moisture. Their inorganic composition prevents the rapid absorption of water that typically leads to softening and structural failure in traditional gypsum panels. In practice, properly manufactured MgO boards retain their shape and strength even when exposed to intermittent water contact or high ambient humidity.

That said, MgO board is not completely impervious to water. Prolonged direct exposure to standing water or continuous high humidity without proper ventilation may still impact the board’s performance over time. Therefore, in bathrooms or kitchens, it is crucial to complement the use of MgO board with suitable surface finishes, sealants, and ventilation to maximize durability.

3.2 MgO Chloride Board vs Magnesium Sulfate Board in Wet Areas

There are two main types of MgO board based on the binder used: magnesium chloride boards and magnesium sulfate boards. The choice between these can affect performance in wet environments:

-

Magnesium Chloride (MgCl₂) Boards

These boards are widely used for general construction and fire-rated applications. While they exhibit good moisture resistance under normal indoor conditions, their prolonged exposure to excessive water or high alkalinity surfaces can potentially cause minor degradation or efflorescence. Proper finishing and protective coatings are recommended to mitigate these risks. -

Magnesium Sulfate (MgSO₄) Boards

Sulfate-based MgO boards generally show enhanced stability in humid and wet areas. They are often preferred in bathrooms and kitchens because they are less reactive with moisture, maintain their dimensional stability longer, and are more compatible with tile adhesives and waterproof coatings.

Choosing the appropriate type of MgO board, combined with correct installation practices, can ensure reliable performance in wet environments. For bathrooms and kitchens, most professionals recommend either using sulfate-based MgO boards or applying a protective waterproof layer on chloride-based boards before exposure to moisture.

👉️ See other differences between MgCl2 board and MgSO4 board

4. Mold, Mildew, and Hygiene Considerations

Bathrooms and kitchens are environments where mold and mildew can easily develop due to constant moisture, warmth, and limited ventilation. Once mold forms behind wall finishes or under tiles, it can compromise indoor air quality, damage surrounding materials, and lead to costly repairs. Therefore, the resistance of a board to biological growth is a key factor in determining its suitability for these areas.

Magnesium oxide board has a significant advantage in this respect because it is an inorganic material. Unlike wood-based panels or paper-faced gypsum boards, MgO board does not provide a food source for mold, mildew, or bacteria. As a result, it is far less likely to support biological growth even in high-humidity conditions commonly found in bathrooms and kitchens.

In comparison, traditional gypsum board relies on paper facings that can absorb moisture and become an ideal breeding ground for mold once water penetrates the surface. Similarly, plywood and OSB contain organic fibers that may deteriorate over time when exposed to moisture, leading to swelling, decay, and hygiene concerns. MgO board avoids these issues by maintaining its structural integrity without organic components.

However, it is important to clarify that mold resistance does not eliminate the need for proper design and installation. Surface finishes, waterproof membranes, sealed joints, and adequate ventilation all play essential roles in maintaining a hygienic bathroom or kitchen environment. When MgO board is used as a substrate beneath tiles, coatings, or panels, it contributes to a more stable and mold-resistant system rather than acting as a standalone waterproof barrier.

From a hygiene and indoor environmental quality perspective, magnesium oxide board offers a reliable foundation for bathroom and kitchen constructions, particularly in projects where long-term durability and resistance to moisture-related issues are a priority.

5. Fire Safety Benefits in Kitchens

Kitchens present a higher fire risk compared to most other interior spaces due to the presence of cooking appliances, open flames, hot surfaces, and electrical equipment. For this reason, materials used behind cabinets, around cooking areas, and within wall and ceiling systems must contribute to overall fire safety rather than accelerate fire spread.

Magnesium oxide board is inherently non-combustible, which is one of its most significant advantages in kitchen applications. As an inorganic material, MgO board does not ignite, melt, or release burning droplets when exposed to high temperatures. This characteristic makes it fundamentally different from wood-based panels or plastic-backed boards that may contribute fuel to a fire.

When used as a substrate in kitchen walls or ceilings, MgO board can help limit flame spread and reduce smoke development, providing additional time for occupants to react in the event of a fire. This is particularly important in residential buildings, hotels, and multi-family housing, where kitchen fires are one of the most common causes of interior fire incidents.

It is also common for magnesium oxide boards to be incorporated into fire-rated wall and ceiling assemblies, where their performance is validated through standardized fire tests. While the specific fire classification depends on the board thickness, density, and system design, the non-combustible nature of MgO board makes it a reliable component in fire-conscious kitchen constructions.

For kitchens, MgO board is typically used behind tiles, metal panels, or decorative finishes, rather than as an exposed surface. In such systems, it serves as a stable, fire-resistant backing that enhances the overall safety of the installation without compromising design flexibility.

6. Installation Considerations for Bathrooms and Kitchens

While magnesium oxide board offers strong performance advantages, its successful use in bathrooms and kitchens depends heavily on correct installation practices. In wet and semi-wet areas, MgO board should be viewed as part of a complete system rather than a standalone solution. Proper surface treatment, fastening methods, and detailing are essential to ensure long-term durability.

6.1 Surface Waterproofing and Finishing

Although MgO board demonstrates good resistance to moisture, it is not designed to remain permanently exposed to water. In bathrooms and kitchens, the board should always be protected with appropriate surface finishes.

Common finishing methods include ceramic tiles, waterproof coatings, PVC panels, or decorative laminates. Before applying these finishes, a compatible waterproof membrane or primer is often recommended, especially in shower areas, behind sinks, and near cooking zones. This additional layer helps prevent prolonged moisture penetration and protects the board and underlying structure.

Tile adhesives and coatings should be selected according to the manufacturer’s recommendations and local standards. Ensuring proper curing times and full coverage is critical to avoid moisture paths that could compromise the system over time.

6.2 Framing, Fasteners, and Joint Treatment

MgO boards can be installed on both metal and timber framing systems, provided that the supporting structure is dry, stable, and properly aligned. In bathroom and kitchen applications, corrosion-resistant fasteners such as stainless steel or treated screws are strongly recommended.

Board joints should be reinforced and sealed using appropriate joint compounds, tapes, or sealants designed for wet environments. Special attention should be paid to corners, penetrations, and service openings, as these areas are most vulnerable to moisture ingress.

Adequate ventilation is another critical factor. Even the best moisture-resistant boards can be affected by persistent condensation if airflow is insufficient. Proper mechanical or natural ventilation helps maintain a stable indoor environment and extends the service life of the entire wall or ceiling system.

When installed following best practices, magnesium oxide board provides a reliable and durable substrate for bathroom and kitchen constructions, supporting both performance and long-term maintenance requirements.

7. Common Applications in Bathrooms and Kitchens

Thanks to its combination of moisture resistance, fire performance, and dimensional stability, magnesium oxide board is commonly used in a variety of bathroom and kitchen applications. In most cases, MgO board serves as a substrate or backing material, rather than an exposed finished surface.

One of the most common uses of MgO board in bathrooms is as a wall backing board behind ceramic or porcelain tiles. Its stable structure provides a solid base for tile installation, helping to reduce cracking and long-term deformation in humid environments. MgO board is also used in shower enclosures, vanity walls, and wet-area partitions when combined with proper waterproof membranes.

In ceilings, MgO board is often selected for bathrooms and kitchens where moisture resistance and fire safety are required. Compared to standard gypsum ceiling boards, MgO board offers improved durability in areas subject to steam and condensation, particularly when ventilation is limited.

For flooring systems, magnesium oxide board can be used as an underlayment or subfloor panel, especially under tiles or waterproof flooring finishes. In bathroom and kitchen floors, this application benefits from the board’s rigidity and resistance to moisture-related swelling when installed correctly.

In kitchens, MgO board is frequently applied behind cabinets, appliances, and wall finishes where enhanced fire resistance is desirable. It can also be used in service shafts, pipe enclosures, and technical spaces where both hygiene and fire performance are critical.

Across all these applications, MgO board is typically integrated into a layered system that includes waterproofing, surface finishes, and proper detailing. When used in this way, it provides a reliable foundation for bathroom and kitchen constructions without compromising safety or durability.

8. Limitations and Best Practices

While magnesium oxide board offers numerous advantages for bathrooms and kitchens, it is important to understand its limitations and follow best practices to ensure long-term performance.

Limitations

-

Direct Water Exposure

MgO board is moisture-resistant but not completely waterproof. Prolonged contact with standing water or continuous immersion can still lead to degradation, especially for chloride-based boards. Proper waterproofing is essential in wet zones such as shower enclosures or around sinks. -

Quality Variations

Not all MgO boards are manufactured to the same standard. Boards from different manufacturers may vary in density, binder type, and additive composition, which can affect moisture resistance, fire performance, and dimensional stability. -

Surface Preparation Requirements

MgO board requires appropriate surface finishing and sealing before tile installation or painting. Improper preparation can reduce its durability and allow moisture to penetrate the system. -

Handling and Cutting

Although easier to cut than cement boards, MgO boards can generate dust and require proper protective equipment during installation. Edges must be treated carefully to prevent chipping.

Best Practices

-

Choose the Right Board Type: For wet areas, sulfate-based MgO boards or chloride-based boards with additional waterproof coating are recommended.

-

Apply Waterproof Membranes: Always use a compatible waterproofing layer in wet zones.

-

Seal Joints and Penetrations: Use appropriate joint compounds, tape, and sealants to prevent water ingress.

-

Ensure Adequate Ventilation: Proper airflow reduces condensation and prolongs board life.

-

Follow Manufacturer Guidelines: Adhere to recommended fasteners, installation spacing, and finishing methods.

By understanding both the limitations and best practices, builders, designers, and homeowners can maximize the performance of magnesium oxide board in bathrooms and kitchens, ensuring safety, durability, and hygiene.

9. Conclusion

Magnesium oxide board demonstrates strong performance characteristics that make it a viable option for use in bathrooms and kitchens. Its moisture resistance, dimensional stability, fire safety, and resistance to mold and mildew provide clear advantages over traditional gypsum or wood-based panels when properly selected and installed.

However, successful application depends on choosing the right type of MgO board, implementing appropriate waterproofing measures, sealing joints and penetrations, and ensuring adequate ventilation. Following these best practices allows MgO board to serve as a reliable substrate for walls, ceilings, and floors in wet and semi-wet areas.

In summary, magnesium oxide board can be used in bathrooms and kitchens, provided that installation is carried out with attention to moisture management and system design. By integrating MgO board into a complete construction system, designers and builders can achieve durable, safe, and hygienic interior environments in spaces that are constantly exposed to moisture and fire risks.

Learn how to use Magnesium Oxide (MgO) board for roofing. Explore types, installation steps, advantages, and precautions for durable, fire-resistant roofs.

Explore Russia’s growing demand for MgO board in 2026. Learn about key applications, fire-safe performance, and market opportunities.

Discover how MgO board enhances prefab houses with fire resistance, moisture protection and eco-friendly benefits for modern modular construction.