Table of Contents

Ask Us Any Question

Introduction

MgO board, or magnesium oxide board, has become a popular choice for construction projects due to its durability, fire resistance, and moisture-handling capabilities. Many builders and homeowners are curious: is MgO board truly waterproof?

In this article, we will explore the water behavior of MgO board, including its moisture resistance, absorption rate, and performance in everyday wet environments. By understanding how MgO boards interact with water, you can make informed decisions about their use in bathrooms, kitchens, and other moisture-prone areas.

What is MgO Board?

Magnesium oxide board, commonly known as MgO board, is a high-performance building material widely used in modern construction. It is valued for its durability, fire resistance, and moisture resistance, making it suitable for a variety of structural and interior applications.

Composition of MgO Board

MgO board is primarily composed of magnesium oxide (MgO) combined with other compounds such as magnesium chloride (MgCl₂) or magnesium sulfate (MgSO₄). Lightweight fillers and reinforcing fibers are also included to enhance strength, reduce weight, and improve workability.

Key Properties and Applications

-

Fire-resistant: Can withstand high temperatures without burning or emitting toxic fumes

-

Moisture-resistant: Maintains stability in humid environments

-

Durable and lightweight: Easy to handle and install in various construction settings

-

Common applications: Interior walls, ceilings, bathroom partitions, kitchen panels, and other areas where durability and resistance to moisture are important

Waterproof vs Water-Resistant: Understanding the Difference

When discussing building materials like MgO board, it’s important to understand the distinction between waterproof and water-resistant. These terms are often used interchangeably, but they represent different levels of protection against moisture.

What Does Waterproof Mean?

A material labeled as waterproof is completely impervious to water. It will not allow water to pass through under any conditions, whether exposed to rainfall, splashes, or immersion. Examples of waterproof materials include certain plastics, rubber membranes, and specialized coatings.

What Does Water-Resistant Mean?

Water-resistant, or moisture-resistant materials can withstand some exposure to water without significant damage, but they are not completely impervious. MgO board falls into this category: it can resist moisture and prevent water damage in typical construction environments, but it is not entirely waterproof.

In practical terms, if MgO board is subjected to prolonged or continuous water exposure, it may start to absorb moisture over time. However, in everyday applications such as bathroom walls, kitchen panels, or interior partitions, the board’s resistance to water is sufficient to maintain performance without structural issues.

Why MgO Board Cannot Be Considered Fully Waterproof

-

The board has microscopic pores on its surface, so a small amount of water can penetrate under extreme conditions

-

Edges and joints are more vulnerable to moisture, requiring proper sealing for critical applications

-

While the board is highly resistant to moisture, complete immersion or continuous water flow will eventually lead to some water absorption

MgO Board’s Water Resistance Performance

MgO board is known for its high moisture resistance, making it suitable for areas where occasional contact with water is expected. Understanding how it behaves under different conditions can help builders and homeowners make informed decisions about its use.

Water Flow Behavior

When an MgO board is positioned vertically or at an angle, and water is poured onto its surface, most of the water flows off along the board’s surface. Only a very small amount penetrates the board through microscopic pores. This natural water-shedding ability makes it effective in areas where water may splash or spill.

Water Absorption and Testing

The water absorption rate of standard MgO boards is approximately 20%. This value is typically determined through a controlled experiment in which the board is fully submerged in water for 24 hours, and the difference in weight before and after immersion is recorded.

It is important to note that daily usage conditions rarely involve full immersion, so the actual water exposure is much lower than in laboratory tests.

Performance in Daily Environments

After absorbing moisture, MgO board can gradually release water through its microscopic pores when placed under favorable conditions, such as proper ventilation, exposure to sunlight, mild heating or temperature fluctuations.

This moisture cycling process does not significantly affect the board’s physical performance, ensuring that it remains stable and durable even after repeated exposure to humidity.

Edge and Joint Considerations

While the board’s main surface is highly resistant to water, edges and seams are more susceptible to moisture. Applying proper sealants or waterproof coatings to these areas is recommended for applications in bathrooms, kitchens, or other moisture-prone environments.

Common Applications in Wet Areas

MgO board is widely used in areas where moisture exposure is a concern. In most construction projects, it functions as a backer board or core material, meaning it is covered by tiles, coatings, or other finish layers. This installation method minimizes direct water contact and maximizes long-term stability in wet environments.

Bathroom Walls

Bathrooms are one of the most common areas where MgO boards are used as substrates behind finish materials. Instead of serving as the final exposed surface, MgO board is typically installed behind ceramic tiles, waterproof membranes, or decorative panels. This layered system allows the board to withstand humidity and occasional splashes without swelling or warping. Edge sealing is still recommended to enhance moisture protection.

Kitchen Panels

In kitchens, MgO boards are often applied as a base layer behind backsplashes, tiles, or waterproof panels, especially around sinks and countertops. The board’s low water absorption rate ensures that it remains stable when supporting other finishing materials, even in environments with steam or intermittent splashes.

Balconies, Basements, and Other Wet Areas

For semi-outdoor or humid indoor environments such as balconies, basements, and laundry rooms, MgO board performs well when used as a structural or substrate layer beneath exterior-grade coatings, cement finishes, or waterproof membranes. While the material is not fully waterproof on its own, these finishing layers prevent continuous water exposure and allow the board to maintain long-term performance.

Visual and Design Considerations

MgO board is rarely used as the final decorative surface in wet areas. Instead, it acts as a smooth, stable, and moisture-resistant base for tiles, waterproof coatings, paints, or composite finishes. These finishing materials not only enhance water resistance but also improve the overall aesthetics of bathrooms, kitchens, and other wet environments.

How to Improve Waterproofing of MgO Board

Although MgO board is highly moisture-resistant, it is not completely waterproof. To ensure long-term performance in areas with frequent water exposure, certain precautions and treatments are recommended.

Using Sealants and Waterproof Coatings

One of the most effective ways to improve water resistance is to apply sealants or waterproof coatings to the board’s surface. These treatments prevent water from entering through microscopic pores and enhance durability in wet areas. Popular options include silicone-based sealants, acrylic coatings, or specialized water-resistant paints.

Edge and Joint Protection

Edges and seams are more susceptible to water penetration than the board’s main surface. Proper treatment includes:

-

Applying waterproof sealant along all edges

-

Using joint tape before coating to prevent leaks

-

Ensuring tight fitting of panels to avoid gaps

These measures are particularly important for bathrooms, kitchens, or any environment with frequent splashes or humidity.

Installation Practices

Installation techniques can also affect the board’s water resistance:

-

Avoid placing boards in areas where they will be fully immersed in water

-

Ensure proper ventilation during and after installation

-

Use sloped installations for areas where water might flow over the board

Following these practices ensures that any absorbed moisture can gradually evaporate without affecting the board’s physical properties.

Combining with Other Waterproof Materials

For highly wet environments, MgO board can be combined with additional waterproof layers, such as:

-

Tile backer boards

-

Waterproof membranes

-

Protective coatings under paint or tiles

This layered approach maximizes water resistance while maintaining the board’s lightweight and durable properties.

Pros and Cons of MgO Board in Moisture-Prone Areas

MgO board is widely appreciated for its performance in areas with potential moisture exposure. However, like any building material, it has both advantages and limitations. Understanding these can help you make informed decisions for your construction projects.

Advantages

-

Moisture-resistant: Can withstand occasional water exposure without swelling or warping

-

Fire-resistant: Offers superior safety compared to traditional gypsum boards

-

Lightweight and easy to install: Reduces labor effort and supports flexible design

-

Durable: Maintains physical properties even after repeated moisture absorption and drying cycles

-

Versatile applications: Suitable for interior walls, ceilings, bathrooms, kitchens, and semi-outdoor areas

Limitations

-

Not completely waterproof: Prolonged water exposure or full immersion can lead to water absorption

-

Edges and seams are vulnerable: Require sealing to prevent localized moisture damage

-

Surface treatment may be needed: In areas with heavy splashing, additional coatings or membranes are recommended

Comparison with Other Common Materials

-

Vs Gypsum Board: Gypsum boards have a higher water absorption rate and are more prone to swelling in wet areas, making MgO board a better choice for moisture-prone environments

-

Vs Cement Board: Cement boards are highly waterproof but heavier and more difficult to cut and install, whereas MgO boards provide a balance of water resistance, fire safety, and ease of handling

Conclusion

MgO board, or magnesium oxide board, is a highly durable and moisture-resistant building material. While it is not completely waterproof, its ability to shed water, resist humidity, and gradually release absorbed moisture makes it suitable for bathrooms, kitchens, and other moisture-prone areas.

By understanding the difference between waterproof and water-resistant, and by implementing proper edge sealing, joint protection, and surface treatments, you can ensure that MgO boards maintain their performance and longevity even in wet environments.

Compared to other materials like gypsum board, MgO board offers a balanced combination of fire resistance, water resistance, and ease of installation, making it a reliable choice for both residential and commercial projects.

In summary, is MgO board waterproof? Not completely—but with the right precautions and installation practices, it provides excellent water resistance and durability, meeting the needs of most moisture-exposed construction applications.

Frequently Asked Questions (FAQ)

1. Can MgO board get wet?

Yes, MgO board can get wet occasionally. It is moisture-resistant, meaning it can handle splashes or humidity without significant damage. However, it is not fully waterproof, so prolonged immersion or continuous water exposure should be avoided.

2. How long can MgO board stay in wet areas?

With proper installation and edge sealing, MgO board can perform reliably in wet areas like bathrooms or kitchens for many years. Its ability to shed water and release absorbed moisture ensures long-term stability under typical indoor conditions.

3. Do I need to seal the edges?

Yes. Edges and joints are the most vulnerable areas for moisture penetration. Applying a waterproof sealant or joint tape is recommended to prevent localized water damage and maintain the board’s durability.

4. Is MgO board suitable for outdoor use?

MgO board is generally designed for interior applications. While it has good moisture resistance, exposure to heavy rainfall or outdoor conditions without additional protective measures may lead to water absorption over time. For outdoor use, combining MgO board with waterproof membranes or coatings is advised.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

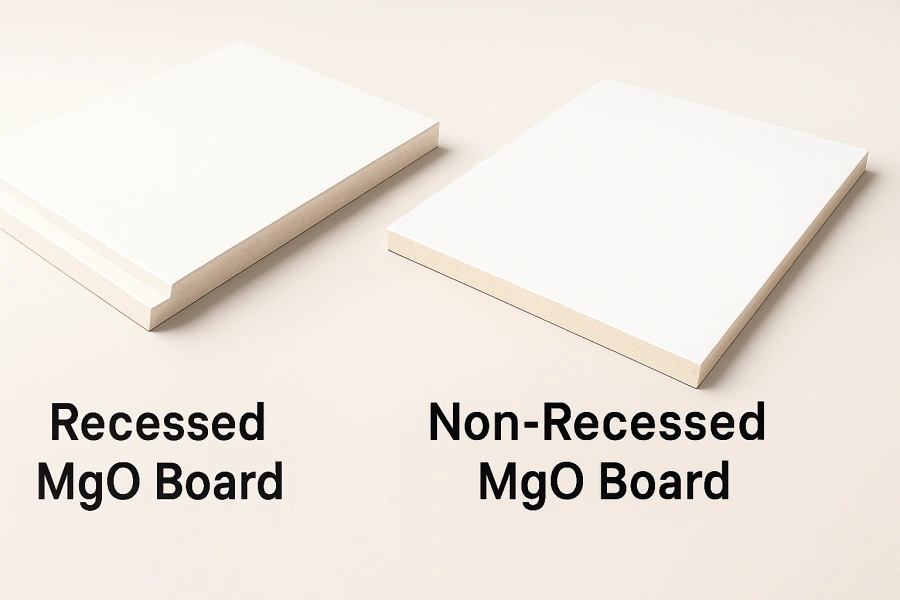

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

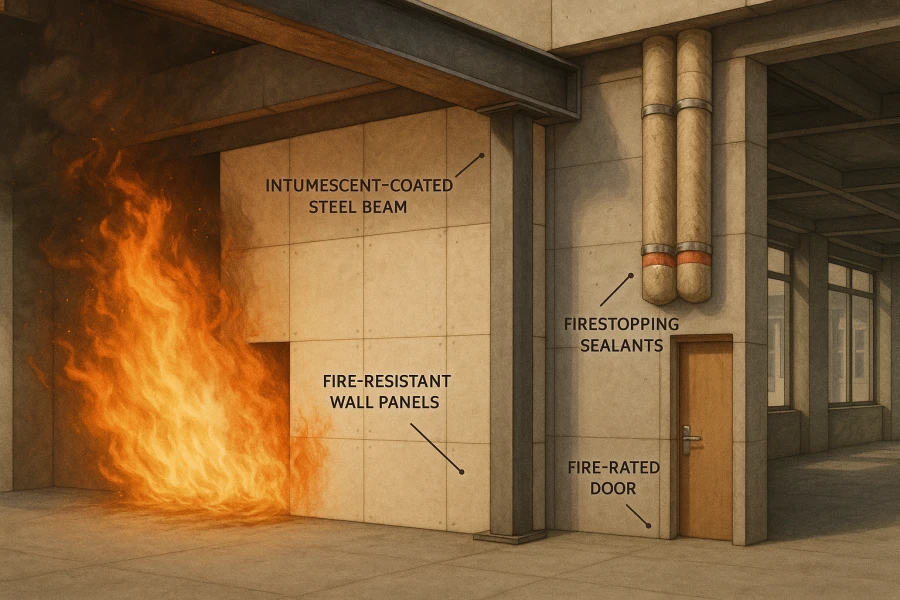

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.