Table of Contents

Ask Us Any Question

Introduction

In modern construction, industrial projects, and even home renovations, selecting the right heat proof material and heat resistant material can mean the difference between safety and disaster. Materials that withstand high temperatures not only protect structures but also extend lifespan and reduce maintenance costs. From residential kitchens to large-scale industrial facilities, different solutions resist heat and fire in unique ways.

This guide explores the top 7 heat proof materials and the 5 key safety gains of heat resistant materials, helping you choose the most suitable options for your next project.

Understanding Heat Proof & Heat Resistant Materials

Heat proof materials are designed to withstand high temperatures without damage, while heat resistant materials maintain structural integrity and safety under extreme conditions. Both types aim to reduce fire hazards, preserve property, and protect occupants.

Common Types

-

MgO Boards – Non-combustible, Class A fire-rated, moisture and mold resistant

-

Gypsum Boards – Cost-effective fire-rated interior walls and ceilings

-

Ceramic Materials – High-temperature industrial and furnace applications

-

Fiber Cement Boards & Calcium Silicate – Durable, moisture-resistant, and fireproof

-

Specialty Composites – Engineered for extreme industrial applications

Top 7 Heat Proof Materials

1. Gypsum Board (Fire-Resistant Drywall)

Overview:

Gypsum board, also known as drywall or plasterboard, is one of the most widely used heat proof materials in residential and commercial construction. Its popularity stems from its affordability, ease of installation, and moderate fire-resistant properties. The core of non-combustible gypsum provides basic fire protection while the paper layers give structural support.

Key Features:

-

Lightweight and Easy to Install: Simple to cut, shape, and fit into walls and ceilings, reducing labor time.

-

Fire Resistance: Gypsum contains water molecules that release steam when heated, slowing fire spread.

-

Cost-Effective: Affordable and widely available for projects with budget constraints.

-

Versatile: Can be painted, textured, or laminated to meet functional or aesthetic needs.

Common Applications:

-

Interior Walls and Partitions: Residential homes, offices, and commercial spaces.

-

Ceilings in Homes and Offices: Provides lightweight, fire-resistant ceiling panels.

-

Temporary Fire Barriers: Used in phased construction to separate areas and reduce fire risk.

2. Calcium Silicate Board

Overview:

Calcium silicate board is a durable, heat proof material known for its excellent fire and moisture resistance. Made by combining silica, lime, and reinforcing fibers, it is stronger than gypsum board and widely used in industrial and commercial construction.

Key Features:

-

High Strength and Stability: Maintains shape and integrity under heat and pressure.

-

Fire and Moisture Resistant: Effective in damp and high-temperature environments.

-

Long Lifespan: Strong and durable, suitable for long-term applications.

Common Applications:

-

Industrial Wall Panels: Tunnel linings, factories, and workshops.

-

Commercial Ceilings: Offices and high-traffic buildings.

-

Fireproof Duct Enclosures: Protects HVAC and electrical installations.

3. Fiber Cement Board

Overview:

Fiber cement board combines cement with cellulose fibers to create a heat proof and fire-resistant material suitable for both interior and exterior applications. It offers strength, moisture resistance, and durability in a lightweight form.

Key Features:

-

Non-Combustible: Provides reliable fire resistance for walls, ceilings, and cladding.

-

Weather and Impact Resistant: Suitable for outdoor use and harsh climates.

-

Moisture and Termite Resistant: Long-lasting and low maintenance.

Common Applications:

-

Exterior Wall Cladding: Residential and commercial façades.

-

Kitchen and Bathroom Partitions: Resists moisture and heat effectively.

-

Fire-Rated Ceiling Systems: Adds fire protection for suspended ceilings.

4. Mineral Wool (Rock Wool & Slag Wool)

Overview:

Mineral wool, including rock wool and slag wool, is an insulating heat proof material made from molten stone or industrial slag. It provides excellent thermal insulation, fire resistance, and acoustic performance.

Key Features:

-

Superior Insulation: Provides excellent thermal and sound insulation.

-

Non-Combustible: Can withstand extremely high temperatures without igniting.

-

Eco-Friendly: Often contains recycled materials and is recyclable.

Common Applications:

-

Fire Doors and Curtain Walls: Improves fire resistance and thermal performance.

-

Roofing Insulation: Protects against heat and reduces energy costs.

-

Industrial Pipes and Furnaces: Safe insulation in high-temperature industrial systems.

5. Vermiculite Board

Overview:

Vermiculite board is a lightweight heat proof material made from exfoliated vermiculite. Its natural mineral composition provides resistance to fire and chemical corrosion while maintaining dimensional stability.

Key Features:

-

Lightweight and Easy to Handle: Simplifies installation and reduces labor.

-

High Fire Resistance: Can withstand high temperatures without structural failure.

-

Stable under Thermal Stress: Maintains integrity under heat exposure.

Common Applications:

-

Fireplace and Stove Linings: Protects surrounding structures from heat.

-

Boiler Insulation Layers: Provides thermal protection in industrial boilers.

-

Heat Shields in Industrial Environments: Safe insulation for machinery and equipment.

6. Magnesium Oxide Board (MgO Board)

Overview:

Magnesium oxide board, commonly called MgO board, is a next-generation heat proof material combining fire safety, durability, and eco-friendliness. Made from magnesium oxide reinforced with fibers, it is non-toxic and highly resistant to fire, moisture, mold, and insects.

Key Features:

-

Non-Combustible and Fireproof: Class A fire rating for walls, ceilings, and partitions.

-

Moisture and Mold Resistant: Ideal for humid or wet environments.

-

Durable and Eco-Friendly: Long-lasting and recyclable without toxic emissions.

Common Applications:

-

Sub-Flooring and Underlayment: Fire-resistant and moisture-stable flooring base.

-

Interior and Exterior Wall Panels: Reliable protection in diverse climates.

-

Fireproof Ceilings and Partitions: Enhances safety in residential and commercial buildings.

7. Ceramic & Refractory Materials

Overview:

Ceramic and refractory materials are engineered to resist extreme heat, making them ideal for high-temperature industrial applications. They offer unmatched fireproofing and durability under conditions where most boards would fail.

Key Features:

-

Extremely Heat-Resistant: Can withstand temperatures above 1,000°C.

-

Durable and Long-Lasting: Resistant to abrasion, chemicals, and thermal cycling.

-

High-Performance for Specialized Use: Suitable for industrial furnaces and kilns.

Common Applications:

-

Industrial Kilns and Furnaces: Protects equipment and maintains thermal efficiency.

-

Steel and Glass Manufacturing Equipment: Resists extreme operational heat.

-

High-Temperature Linings and Fire Chambers: Provides structural integrity and fire protection.

5 Key Safety Gains of Heat Resistant Materials

Safety Gain #1 – Fire Resistance

Heat resistant materials prevent ignition and slow the spread of fire, providing critical extra time for evacuation. Products like MgO boards, ceramic panels, and fire-rated gypsum boards help protect walls, ceilings, and industrial equipment from direct flames. In buildings and factories, this resistance significantly reduces the risk of catastrophic damage and helps contain fire to smaller areas.

Safety Gain #2 – High Thermal Stability

These materials maintain their shape, strength, and performance even under prolonged exposure to high temperatures. MgO boards and ceramic panels resist warping, cracking, or structural degradation, which ensures the overall integrity of walls, floors, and industrial installations. High thermal stability also reduces repair costs and prevents unexpected failures in critical safety zones.

Safety Gain #3 – Enhanced Worker and Occupant Safety

Using heat resistant materials minimizes the risk of burns, injuries, and exposure to harmful fumes. In industrial settings, they protect workers near furnaces or high-temperature machinery. In residential and commercial buildings, fire-rated walls and ceilings slow fire progression, giving occupants additional minutes to evacuate safely, enhancing overall safety for everyone in the space.

Safety Gain #4 – Durability Against Heat Damage

Heat resistant materials are designed for long-term performance, retaining their strength and functionality even after repeated exposure to high temperatures. MgO boards and refractory ceramics withstand thermal cycling without breaking down, which reduces maintenance needs, extends service life, and ensures that safety features remain effective over years of use.

Safety Gain #5 – Environmental and Health Protection

Many heat resistant materials, such as MgO boards, are non-toxic, eco-friendly, and recyclable. They do not release harmful fumes when heated, supporting safer indoor air quality. In industrial applications, their environmental benefits also reduce waste and minimize ecological impact, allowing architects and engineers to combine safety, performance, and sustainability in their projects.

How to Choose the Right Heat Proof & Heat Resistant Material

Application Environment

Consider the specific environment where the material will be used. Walls, ceilings, industrial machinery, and outdoor structures each have different exposure levels to heat, moisture, and fire risk. Selecting a material suited to its environment ensures it performs effectively under expected conditions, whether in residential interiors, commercial buildings, or high-temperature industrial sites.

Material Properties

Evaluate the key properties of potential materials, including thermal stability, fire resistance, durability, and environmental safety. For example, MgO boards offer a balance of fireproofing, moisture resistance, and eco-friendliness, while ceramics excel in extreme heat conditions, and gypsum or calcium silicate boards provide cost-effective protection in moderate-risk areas. Understanding these differences allows for informed material selection.

Cost vs Longevity

While high-quality heat resistant materials may have higher upfront costs, their durability and long-term performance often result in lower maintenance and replacement expenses. Investing wisely ensures that safety and functionality are maintained over the life of the building or facility, providing better value and reliability.

Regulatory Standards

Always verify that chosen materials comply with local fire codes, building regulations, and industry standards. Certified materials ensure safety, avoid legal liability, and give peace of mind that walls, ceilings, or industrial installations will perform as intended during fire or heat exposure.

Conclusion

Selecting the right heat proof and heat resistant materials is crucial for construction safety, long-term durability, and environmental responsibility. From cost-effective gypsum boards to advanced MgO and ceramic solutions, each material has a role in protecting people and property.

By making informed choices, architects, builders, and property owners can ensure fire safety, structural integrity, and sustainability in every project.

📩 Contact us today to discuss your project requirements and get expert guidance.

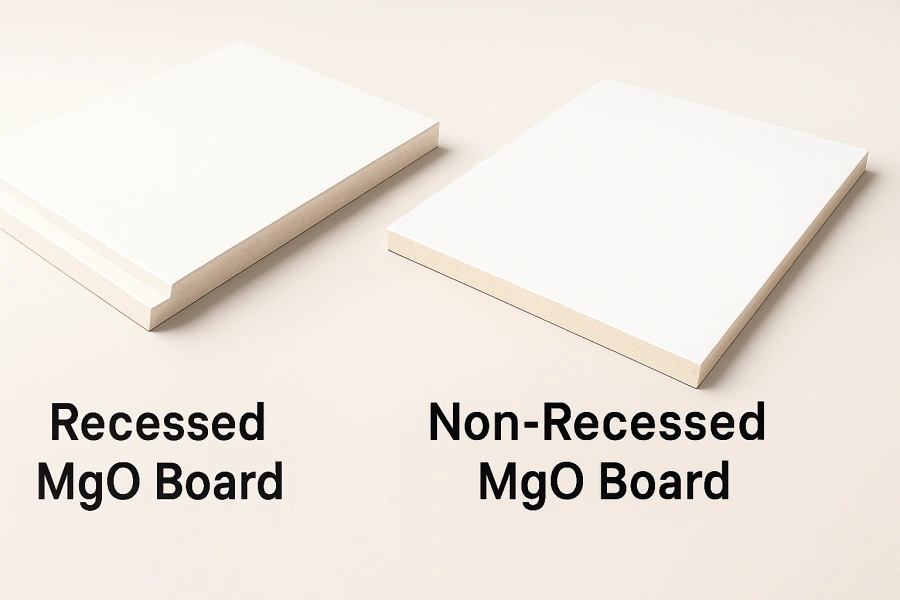

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

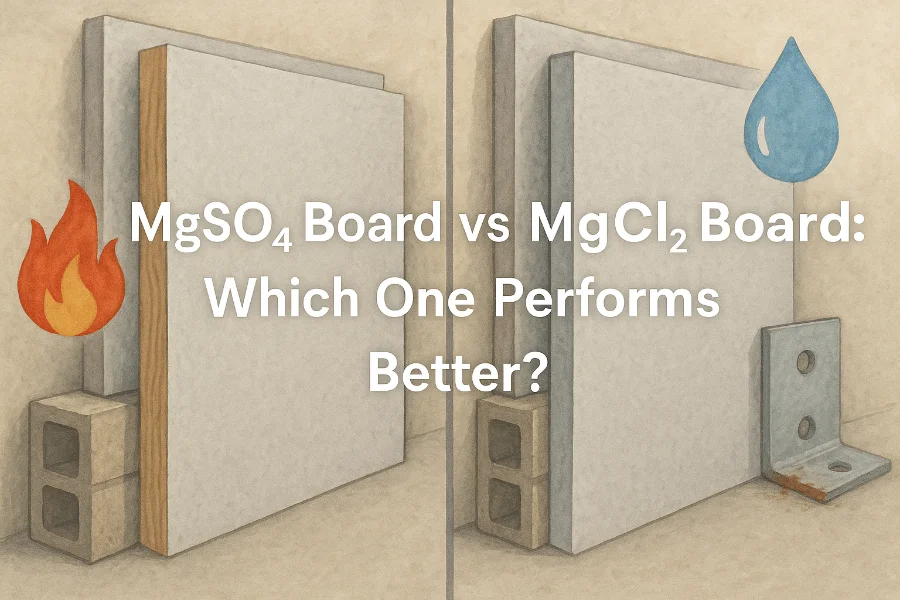

Compare MgSO4 board vs MgCl2 board: discover key differences, performance, and durability to choose the best mgo board for your project.

Discover the top 4 fire rated subfloor materials with pros and cons. Learn which subfloor offers the best fire resistance, durability, and long-term value.