Table of Contents

Ask Us Any Question

1. Introduction

Magnesium oxide board, commonly known as MgO board, has become one of the most popular fireproof and eco-friendly construction materials in modern building projects. But what exactly is MGO board made of? Understanding its composition is essential to appreciate why it performs so well in walls, ceilings, flooring, and other structural applications.

MgO boards are not a single material but a carefully engineered combination of raw materials and components, each serving a specific function. Some ingredients provide strength and fire resistance, others improve moisture stability or reduce weight, and a few enhance surface smoothness and durability.

Knowing the key components and their role in the board’s composition helps builders, architects, and engineers select the right type of MgO board for their projects—whether chloride-based or sulfate-based. It also provides insights into the board’s long-term performance, eco-friendliness, and resistance to fire and moisture.

In this article, we will break down the seven essential ingredients that make up an MgO board, explain how each contributes to the board’s superior performance, and explore how these materials work together to create a safe, durable, and lightweight building solution.

2. Core Binder – Magnesium Oxide (MgO)

At the heart of every MgO board lies magnesium oxide (MgO), the primary binder that gives the board its strength, stability, and fireproof qualities. This mineral is derived from calcined magnesite, a naturally occurring form of magnesium carbonate, and serves as the foundation for the board’s composition.

When combined with an activator and water, MgO undergoes a chemical reaction to form a strong cementitious matrix, either magnesium oxychloride or magnesium oxysulfate, depending on the type of activator used. This reaction is what transforms the individual raw materials and components into a cohesive, high-performance panel.

The inclusion of MgO provides several essential benefits:

-

Fire Resistance: MgO is naturally non-combustible and maintains its structural integrity under high temperatures, making MgO boards ideal for fire-rated walls, ceilings, and floors.

-

Structural Strength: As the core binder, MgO contributes to compressive strength, dimensional stability, and long-term durability.

-

Eco-Friendly: Being inorganic and non-toxic, MgO contains no asbestos or volatile organic compounds (VOCs), making it safe for both construction workers and building occupants.

-

Moisture and Mold Resistance: Its mineral composition resists water absorption and prevents mold growth, enhancing the board’s lifespan and reliability.

3. Activator – Magnesium Chloride (MgCl₂) & Magnesium Sulfate (MgSO₄)

While magnesium oxide (MgO) forms the core binder, it requires an activator to trigger the hardening reaction and transform the mixture into a durable, fireproof board. In MgO board production, the two most common activators are magnesium chloride (MgCl₂) and magnesium sulfate (MgSO₄), each offering distinct advantages depending on the board’s intended application.

3.1 Magnesium Chloride (MgCl₂)

Magnesium chloride is a colorless, flaky crystalline substance. When MgCl₂ is mixed with MgO and water, it forms magnesium oxychloride cement (MOC). This chloride-based system is widely used because it:

-

Sets quickly and provides excellent adhesion

-

Enhances compressive strength and surface smoothness

-

Works well for interior walls, ceilings, and subfloor applications

However, chloride-based boards come with a potential corrosion risk. If unreacted chloride ions remain in the board, they can migrate to the surface or react with metal fasteners, leading to efflorescence or long-term corrosion. To prevent this, high-quality manufacturers, such as Suparna, use a soaking process after initial curing to remove excess chloride ions, ensuring both durability and metal compatibility.

3.2 Magnesium Sulfate (MgSO₄)

Magnesium sulfate is an inorganic compound typically appearing as white crystals or powder. For projects where metal corrosion or moisture exposure is a concern, MgSO₄ serves as a safer alternative. It reacts with MgO to form magnesium oxysulfate cement (MOS), a chloride-free binder system. MgSO₄-based boards provide:

-

Excellent fire resistance and structural strength

-

No risk of efflorescence or metal corrosion

-

Simplified manufacturing and installation, since soaking is unnecessary

Choosing the correct activator is a critical decision for builders and architects. MgCl₂ boards are ideal for fast-setting, smooth-finish applications, while MgSO₄ boards are preferable in environments with high moisture or metal contact.

4. Fillers – Sawdust & Perlite

In addition to the core binder and activator, MgO boards rely on carefully selected fillers to balance weight, strength, and performance. Two of the most important fillers are sawdust (wood fiber) and perlite, both of which contribute unique properties to the board’s composition.

4.1 Sawdust (Wood Fiber)

Sawdust, often sourced from recycled wood or sawmill by-products, serves as a lightweight filler and natural binder. Its inclusion provides several benefits:

-

Flexibility & Toughness: Sawdust reduces brittleness, making the board easier to cut, screw, and handle without cracking.

-

Acoustic Performance: The natural fibers help dampen sound, improving sound insulation in walls and ceilings.

-

Workability & Sustainability: It enhances the board’s workability during installation and supports eco-friendly construction practices.

By incorporating wood fibers, manufacturers ensure that MgO boards remain strong yet manageable, providing a practical solution for builders while promoting environmental responsibility.

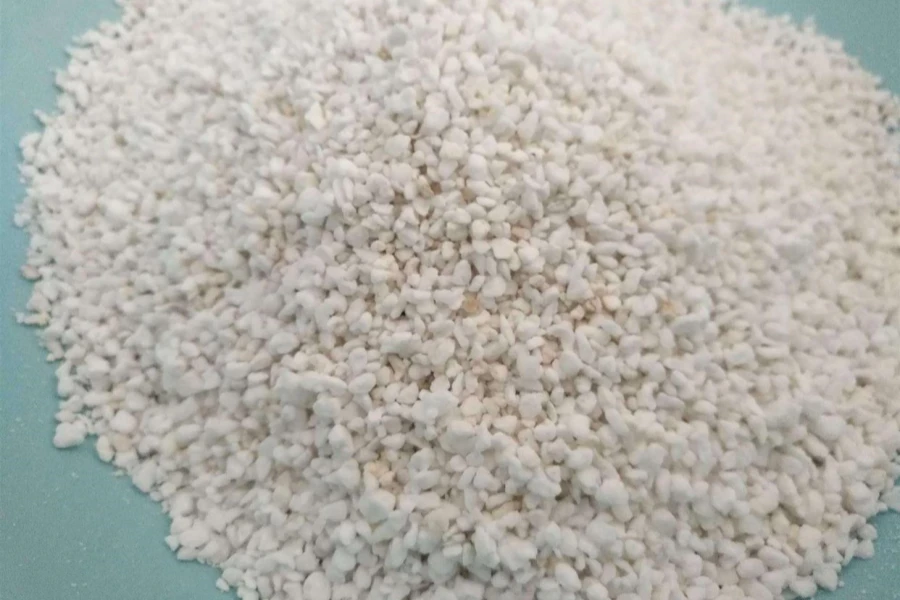

4.2 Perlite

Perlite is a naturally occurring volcanic glass that expands when heated, forming lightweight, porous granules. In MgO board production, perlite acts as a lightweight aggregate, offering several advantages:

-

Weight Reduction: Perlite decreases the overall density of the board, making panels easier to transport and install.

-

Thermal Insulation: Its porous structure traps air, enhancing the board’s thermal performance and energy efficiency.

-

Fire Resistance: Perlite is non-combustible and helps maintain the board’s integrity under high temperatures.

5. Reinforcement – Fiberglass Mesh

To ensure durability and structural stability, MgO boards incorporate fiberglass mesh as a reinforcement layer. While the magnesium oxide core provides compressive strength, fiberglass mesh distributes stress evenly and prevents cracking under bending, impact, or installation forces.

Key Benefits of Fiberglass Reinforcement

-

Crack Resistance: The embedded mesh minimizes the risk of cracks forming during cutting, transportation, or installation.

-

Enhanced Strength: Fiberglass complements the core binder, improving the board’s flexural and tensile strength.

-

Dimensional Stability: It helps maintain panel shape and prevents warping or deformation, even in high humidity or fluctuating temperatures.

6. Surface Layer – Non-woven Fabric

The final component in many MgO boards is the non-woven fabric applied as a surface layer. This layer not only protects the board during handling and installation but also improves its overall performance and finish quality.

Key Benefits of Non-woven Fabric

-

Smooth Surface Finish: Non-woven fabric enhances the board’s flatness and also prevents the slurry from sticking to the rollers during production, ensuring a cleaner and more consistent surface.

-

Improved Bonding: It strengthens the adhesion between the core and surface coatings, reducing the risk of delamination over time.

-

Handling Protection: The surface layer acts as a buffer against minor scratches, impacts, and abrasions during transportation and construction.

7. Manufacturing Overview – How Components Work Together

Understanding the composition of MgO board is important, but seeing how the raw materials and components come together in the manufacturing process highlights why these boards perform so well. Every ingredient plays a distinct role in creating a durable, fire-resistant, and lightweight panel.

Step 1: Material Preparation & Mixing

Precise amounts of magnesium oxide, magnesium chloride (MgCl₂) or magnesium sulfate (MgSO₄), sawdust, perlite, and other additives are measured according to the production formula.

All raw materials are then transferred into a high-speed mixer, where they are blended into a uniform cementitious slurry with consistent viscosity. Proper mixing ensures stable board density and long-term performance.

Step 2: Board Forming & Layering

The slurry is poured onto flat forming templates and evenly spread into continuous sheets. During this process:

-

Fiberglass mesh is embedded to provide tensile strength and crack resistance.

-

Non-woven fabric is layered to improve surface flatness, enhance bonding, and prevent the slurry from sticking to production rollers.

This forms the initial structural framework of the MgO board.

Step 3: Cutting

The wet sheets pass through rollers that applies controlled pressure to ensure consistent thickness and density. Once partially cured, the boards are cut into required sizes using industrial cutting machines, producing clean edges and precise dimensions.

Step 4: Curing & Post-Treatment

Boards enter the first curing stage, where temperature and humidity are carefully regulated to allow initial solidification. After demolding, they undergo a second curing phase at room temperature, during which internal chemical reactions continue to strengthen the board.

For chloride-based MgO boards, an optional soaking process is applied to remove excess chloride ions. This step helps prevent efflorescence and protects metal fasteners from long-term corrosion risks.

Boards are then dried—either naturally or in a controlled chamber—to achieve optimal moisture content.

Step 5: Final Inspection & Quality Control

Each board undergoes strict testing for:

-

Strength and load-bearing performance

-

Dimensional accuracy

-

Fire resistance rating

-

Surface finish and flatness

-

Moisture and corrosion stability

Only panels meeting all quality standards proceed to packaging and shipment.

Through this careful process, the separate components work together to create a balanced, high-quality MgO board that excels in fire resistance, moisture stability, structural strength, and environmental friendliness.

8. Performance & Benefits

Each component in an MgO board contributes to its overall performance, safety, and durability. By understanding how the raw materials and composition work together, builders, architects, and engineers can make informed choices for their construction projects.

Fire Resistance

The combination of magnesium oxide, perlite, and the proper activator gives MgO boards outstanding fireproof properties. Unlike gypsum boards, MgO maintains structural integrity even under extreme heat, making it ideal for fire-rated walls, ceilings, and floors.

Structural Strength

The core binder and fiberglass mesh reinforcement create a panel that is both strong and flexible. MgO boards resist bending and cracking while supporting heavy finishes, ensuring long-term stability for walls, partitions, and subfloors.

Moisture & Mold Resistance

Being inorganic, MgO resists water absorption and mold growth. When combined with appropriate fillers and a well-cured activator system, the boards remain dimensionally stable in humid environments, making them suitable for bathrooms, kitchens, and areas with metal structures.

Lightweight & Workable

Sawdust and perlite reduce overall density without sacrificing strength. This makes boards easier to transport, cut, and install, improving construction efficiency and reducing labor costs.

Eco-Friendly & Safe

MgO boards are non-toxic, free of asbestos and volatile organic compounds (VOCs), and often incorporate recycled materials like sawdust. They align with sustainable building practices and green construction standards.

Versatility

With careful selection of activators (MgCl₂ or MgSO₄) and fillers, MgO boards can be customized for specific applications, including interior partitions, ceilings, subfloors, and exterior sheathing. This flexibility makes them a preferred choice for residential, commercial, and industrial projects.

By combining these benefits, MgO boards offer a balanced solution that addresses fire safety, structural reliability, moisture resistance, and environmental responsibility. Understanding the composition and key components ensures that the boards are used effectively, maximizing performance and longevity.

9. Conclusion

Understanding what an MgO board is made of reveals why it has become a preferred material in modern construction. Each raw material and component—from magnesium oxide, the core binder, to the activators (MgCl₂ or MgSO₄), fillers like sawdust and perlite, fiberglass mesh, and non-woven fabric—plays a crucial role in creating a high-performance, durable, and eco-friendly board.

By carefully selecting the activator and ensuring high-quality manufacturing, builders can maximize the performance and lifespan of MgO boards. With this knowledge, architects, engineers, and construction professionals can make informed decisions when choosing MgO boards for their projects, ensuring safety, durability, and efficiency.

At Suparna, we combine premium raw materials with precise production techniques to deliver MgO boards that meet international standards and the diverse needs of modern construction. From fireproof walls to moisture-resistant ceilings, these boards offer a reliable, sustainable, and high-quality solution for every building project.

If you need technical guidance, samples, or a customized MgO board solution for your project, our team is ready to help.

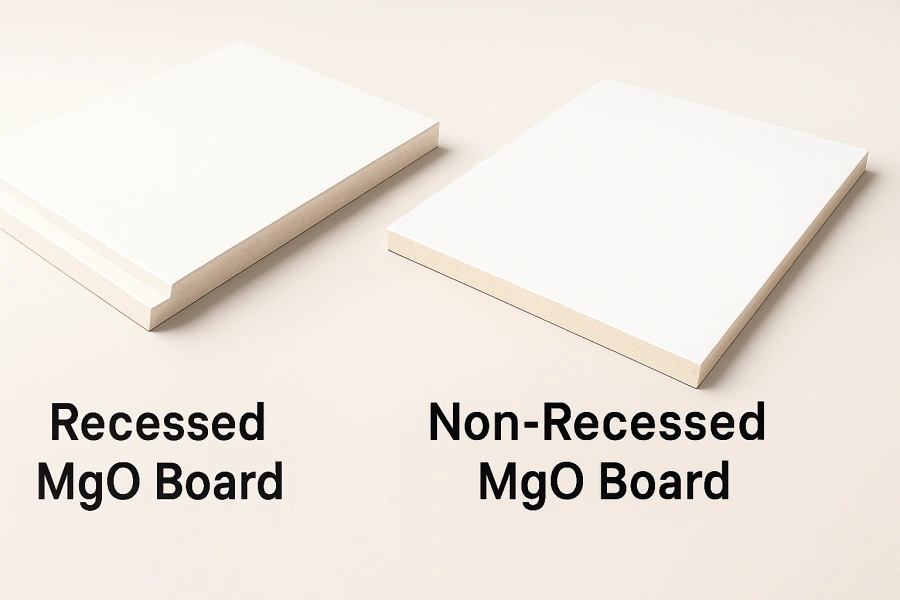

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

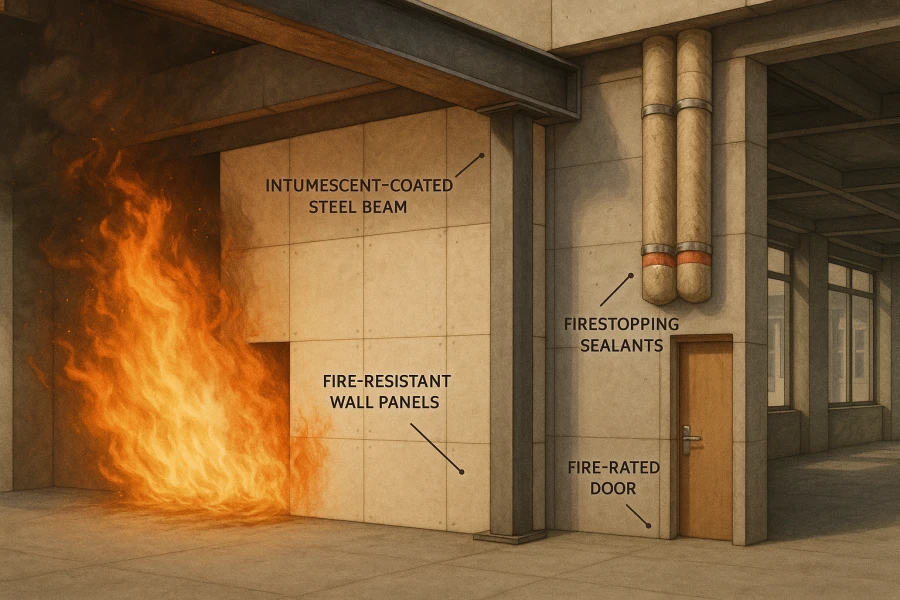

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.

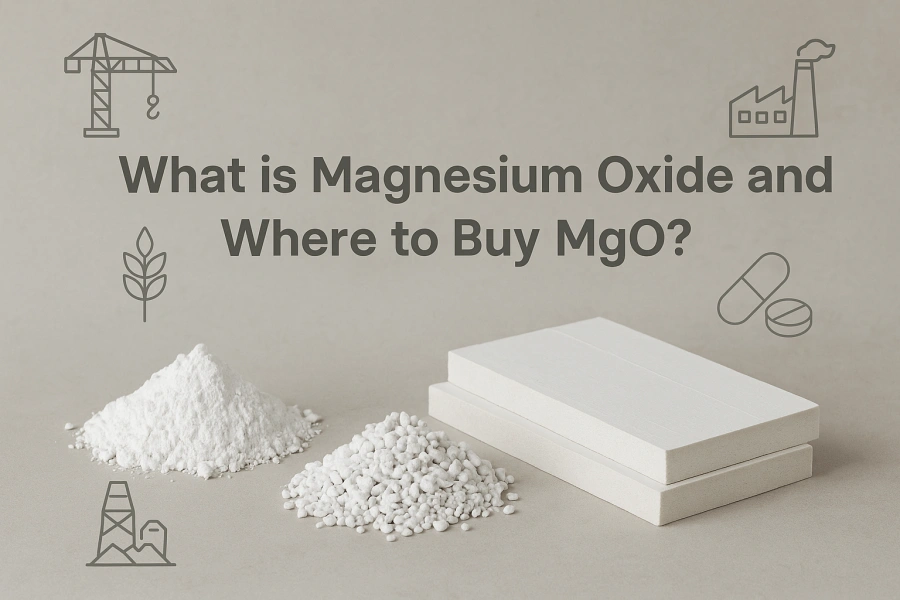

Discover what magnesium oxide (MgO) is, its key properties, applications, and where to buy high-quality MgO.