Table of Contents

Ask Us Any Question

Introduction

In modern construction, safety and energy efficiency are top priorities. MGO Insulated Panels (also called mgo insulated boards) have emerged as a reliable solution that meets these demands. Combining the strength and fire-resistant properties of magnesium oxide boards with effective thermal insulation, these panels offer a versatile option for both residential and commercial buildings.

Builders and architects increasingly prefer MGO Insulated Panels for projects where durability, sustainability, and fire safety are essential. Beyond protection, they contribute to better energy performance, helping buildings stay comfortable while reducing heating and cooling costs.

With this combination of safety, efficiency, and versatility, mgo insulated boards are becoming a cornerstone in modern construction projects worldwide.

What Are MGO Insulated Panels?

Material Composition and Structure

MGO Insulated Panels are composite boards made by sandwiching a core insulation material between two layers of magnesium oxide (MgO) boards. The MgO layers provide excellent fire resistance, moisture protection, and structural strength, while the core—commonly made of materials like EPS (expanded polystyrene), PU (polyurethane), or mineral wool—ensures superior thermal insulation. This combination creates a lightweight yet durable panel suitable for various building applications.

Difference from Standard MGO Boards

Unlike standard MGO boards, which are single-layer panels primarily used for walls, ceilings, or flooring, mgo insulated boards incorporate a thermal insulation layer. This makes them ideal for projects that require both fire safety and energy efficiency. In essence, all insulated panels are MGO boards at their surface, but not all MGO boards include insulation.

Typical Sizes and Specifications

These panels come in various thicknesses depending on the insulation and structural requirements, typically ranging from 50 mm to 150 mm. Standard lengths and widths can be customized, making them adaptable to residential walls, commercial façades, industrial facilities, and cold storage areas.

Top Benefits of MGO Insulated Panels

1. Superior Fire Resistance

One of the primary advantages of mgo insulated boards is their exceptional fire resistance. The magnesium oxide layers are non-combustible, providing a safe barrier against flames. This feature is particularly important for residential and commercial buildings, helping protect both property and occupants while meeting stringent fire safety regulations.

2. Excellent Thermal Insulation

The insulated core significantly reduces heat transfer, making mgo insulated boards highly effective in maintaining indoor temperature. This improves energy efficiency by lowering heating and cooling costs, which is especially valuable in climates with extreme temperatures.

3. Moisture and Mold Resistance

Unlike traditional gypsum or timber boards, mgo insulated boards resist moisture and prevent mold growth. The MgO layers do not absorb water, ensuring long-term durability even in humid environments or areas exposed to occasional water contact.

4. Durability and Structural Strength

These panels are known for their high compressive and flexural strength. MGO Insulated Panels can withstand mechanical stress, making them suitable for load-bearing walls and partitions. They are also resistant to cracks, shrinkage, and deformation, providing a stable and long-lasting solution.

5. Eco-Friendly and Sustainable

Manufactured using natural magnesium oxide and recyclable materials, mgo insulated boards have a low environmental impact. They emit no harmful chemicals, contribute to sustainable construction, and align with green building standards.

6. Lightweight and Easy Installation

Despite their strength, MGO Insulated Panels are lightweight, reducing transportation and labor costs. They can be quickly cut, handled, and installed on-site, which accelerates construction schedules and simplifies assembly in large-scale projects.

7. Versatile Applications

From residential walls and commercial façades to industrial buildings and cold storage facilities, mgo insulated boards adapt to various construction needs. Their combination of fire safety, insulation, and durability makes them a preferred choice for architects and builders worldwide.

Applications of MGO Insulated Panels

Residential Buildings

In modern homes, MGO Insulated Panels are commonly used for interior and exterior walls, ceilings, and partitioning. Their fire-resistant and insulating properties provide a safe and comfortable living environment, while their moisture resistance ensures longevity even in humid areas such as kitchens and bathrooms.

Commercial Buildings

From office complexes to shopping centers, mgo insulated boards enhance safety and energy efficiency. They help maintain consistent indoor temperatures, reduce energy consumption, and meet fire safety codes, making them a reliable choice for large-scale commercial projects.

Industrial Facilities and Cold Storage

The thermal insulation of mgo insulated boards makes them ideal for factories, warehouses, and refrigerated storage rooms. They maintain temperature control while providing fire protection, ensuring operational safety and product integrity.

Green and Energy-Efficient Buildings

Architects and builders increasingly rely on mgo insulated boards for sustainable construction projects. Their eco-friendly materials, combined with energy-saving insulation, support green building certifications and contribute to a reduced carbon footprint.

Why Choose MGO Insulated Panels for Your Project?

Long-Term Cost Savings

While the initial investment in MGO Insulated Panels may be slightly higher than conventional boards, their durability, fire resistance, and thermal insulation lead to significant long-term savings. Reduced maintenance costs and lower energy bills make them a cost-effective choice over the building’s lifespan.

Enhanced Building Safety and Comfort

Safety is paramount in any construction project. MGO Insulated Panels provide superior fire protection and moisture resistance, creating a safer environment for occupants. Additionally, their thermal insulation keeps indoor spaces comfortable year-round, improving overall living and working conditions.

Comparison with Other Materials

Compared to traditional materials like gypsum boards, timber panels, or standard concrete walls, mgo insulated boards offer a balanced combination of fire safety, structural strength, and energy efficiency. They are lighter than concrete walls, more moisture-resistant than timber, and more thermally efficient than plain MGO boards.

Adaptability and Versatility

Whether for residential, commercial, or industrial projects, MGO Insulated Panels adapt to various construction needs. Their customizable sizes and finishes allow architects to integrate them seamlessly into modern designs while maintaining safety and sustainability standards.

Conclusion

MGO Insulated Panels offer a unique combination of fire resistance, thermal insulation, durability, and eco-friendliness, making them an ideal choice for modern construction projects. Whether you are building residential homes, commercial spaces, or industrial facilities, these panels enhance safety, comfort, and energy efficiency.

By choosing mgo insulated boards, you invest in a material that not only protects your property and occupants but also contributes to sustainable building practices. Their lightweight design, easy installation, and versatile applications make them a practical and reliable solution for a wide range of construction needs.

Ready to upgrade your building projects with MGO Insulated Panels? Contact us today to learn more about our products, request a quote, or explore customized solutions tailored to your project requirements.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

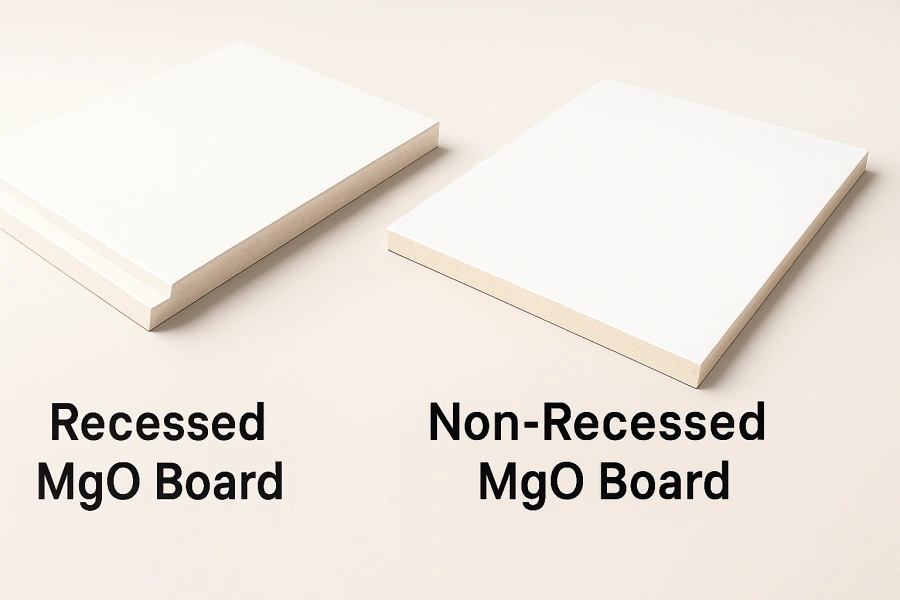

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

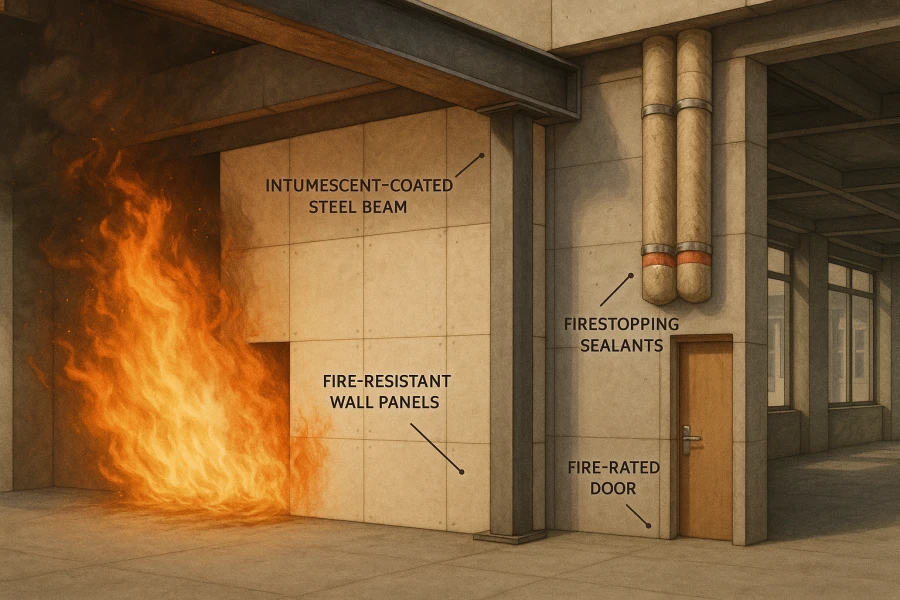

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.