Table of Contents

Ask Us Any Question

Introduction

Magnesium Oxide (MgO) is a versatile material widely used in multiple industries, from construction and agriculture to refractories and environmental solutions. Its two most common forms are MgO powder (light-burned, dead-burned, or fused magnesia) and MgO boards, which are increasingly popular as sustainable fire-resistant building materials.

When we talk about an MGO company, the meaning can be twofold:

-

A supplier of magnesium oxide raw materials such as powders and granules, serving industries like steelmaking, chemicals, and farming.

-

A manufacturer of MgO boards, producing panels for walls, ceilings, flooring, and fire-rated applications in modern buildings.

Both roles are deeply connected. Board manufacturers rely on high-quality MgO raw materials to ensure their products meet fire-safety and durability standards. On the other hand, raw material suppliers often find their products being used by board factories across global markets.

Selecting the right MGO company—whether raw material supplier or board manufacturer—plays a decisive role in the success of your project. A trusted partner ensures stable supply, consistent quality, and long-term value, while a poor choice can lead to costly delays, compliance issues, or safety risks.

What Is an MGO Company?

An MGO company is a business engaged in the production or supply of magnesium oxide in various forms. Broadly speaking, there are two major categories:

-

Magnesium Oxide Raw Material Suppliers

These companies mine and process magnesite ore into MgO powder, granules, or specialized grades such as light-burned, dead-burned, or fused magnesia. Their products are widely used in industries including:-

Steel & Refractories: as a key component in furnace linings and heat-resistant bricks.

-

Chemical Industry: for desulfurization, wastewater treatment, and catalyst applications.

-

Agriculture: as a magnesium supplement for animal feed or soil treatment.

-

Environmental Solutions: in flue gas treatment and waste neutralization.

-

-

Magnesium Oxide Board Manufacturers

These companies specialize in producing MgO boards, which are engineered panels combining strength, fire resistance, and eco-friendliness. Applications include:-

Residential and commercial buildings (walls, ceilings, floors).

-

Fire-rated assemblies in public spaces.

-

Modular and prefabricated housing.

-

Decorative or structural uses in green building projects.

-

While these two types of companies operate in different segments, they are closely connected. High-quality MgO powder is the foundation for durable MgO boards, and many board manufacturers rely on long-term partnerships with raw material suppliers.

In short, when we refer to an MGO company, it could mean a raw material supplier, a board producer, or in some cases—both under one roof.

Why the Right MGO Company Matters

Choosing the right MGO company is not just about comparing prices. The quality, stability, and reliability of your supplier or manufacturer will directly affect your project’s outcome.

-

Impact of Raw Material Quality

For industries using magnesium oxide powder, factors like purity, chemical stability, and particle size consistency are crucial. Low-grade MgO with impurities can reduce efficiency in steelmaking, cause uneven reactions in agriculture, or fail to meet chemical requirements. Over time, such problems increase costs rather than saving them. -

Impact of MgO Board Performance

In the construction sector, boards must meet strict requirements for fire resistance, strength, and durability. A substandard MgO board may crack, warp, or fail under fire tests. Such failures not only delay projects but also expose contractors to serious legal and safety risks. -

Risks of Choosing the Wrong Supplier

-

Project delays caused by unstable supply or inconsistent quality.

-

Rework and additional costs when materials do not meet specifications.

-

Compliance issues if products lack proper certifications for your target market.

-

Damage to reputation for contractors or distributors relying on poor-quality products.

-

On the other hand, the right MGO company becomes a strategic partner. They ensure stable deliveries, provide technical support, and maintain consistent standards across every batch. This reliability reduces risks, builds trust with end-users, and safeguards both the financial and safety aspects of a project.

In short, whether you need raw magnesium oxide or finished MgO boards, the company you choose directly shapes the success or failure of your business operations.

6 Key Factors to Evaluate an MGO Company

1. Product Quality and Consistency

The most important criterion when assessing an MGO company is the quality and consistency of its products. This applies both to magnesium oxide raw materials and MgO boards.

-

For MgO Powder Suppliers:

Product quality is measured by MgO content, particle size, and chemical purity. High-grade MgO ensures predictable performance in industrial applications, whether for steelmaking, refractory bricks, or chemical processes. Trusted companies provide independent test reports and certifications, such as ISO, ASTM, or EN, to verify the purity and stability of their products. -

For MgO Board Manufacturers:

Quality includes not only chemical composition but also mechanical properties. Boards must maintain consistent fire resistance, flexural strength, and dimensional stability. Certified boards meet international fire safety standards and withstand variations in humidity or temperature without warping or cracking. -

Consistency Matters:

Beyond single-batch quality, a reliable MGO company ensures that every shipment—whether powder or board—meets the same standards. Inconsistent products can cause production delays, construction issues, and higher operational costs. -

Value of Verification:

Before committing to a supplier, it’s wise to request samples and third-party reports. A company willing to provide transparent data demonstrates commitment to quality and builds trust.

In summary, product quality and consistency are the foundation of any smart decision when choosing an MGO company. Whether sourcing raw magnesium oxide or ready-to-use boards, quality determines performance, safety, and long-term reliability.

2. Production Capacity and Technology

Another crucial factor when evaluating an MGO company is the production capacity and technology it employs. Reliable companies combine advanced equipment with efficient processes to meet both quality and demand.

-

For MgO Powder Suppliers:

Production capacity depends on the scale of the kilns, the type of calcination (light-burned, dead-burned, or fused), and raw material availability. High-capacity suppliers can fulfill both small test orders and large-scale industrial contracts. Advanced technology ensures uniform particle size, consistent chemical composition, and reduced impurities, which are essential for industries like steel, refractory, and chemical manufacturing. -

For MgO Board Manufacturers:

Capacity is determined by production lines, curing chambers, and automation levels. Modern board production technology allows for customized sizes, thicknesses, and densities, while maintaining fire-resistance and dimensional stability. Companies with automated lines and strict process control can produce thousands of square meters per day, ensuring timely delivery for large construction projects. -

Importance of Technology:

Advanced production methods also improve efficiency and sustainability. For powder suppliers, this might mean energy-efficient kilns; for board manufacturers, optimized curing and low-chloride processing reduces defects and extends board lifespan. -

Why It Matters:

Without sufficient production capacity, even the highest-quality MgO products cannot support ongoing projects. Delays can lead to costly interruptions, while outdated technology can compromise quality and consistency.

In conclusion, when choosing an MGO company, evaluating both production capacity and technological capabilities is essential to ensure reliable, high-quality supply for your project—whether you are sourcing raw magnesium oxide or finished MgO boards.

3. Range of Applications

When considering an MGO company, the range of applications its products support is a key factor in assessing versatility and reliability. A company with diverse applications demonstrates both technical expertise and market adaptability.

-

For Magnesium Oxide Raw Material Suppliers:

High-quality MgO powders are used across multiple industries:-

Steel & Refractories: As a key component in furnace linings and refractory bricks, providing heat resistance and chemical stability.

-

Chemical Industry: In wastewater treatment, flue gas desulfurization, and catalyst production.

-

Agriculture: As a magnesium supplement for animal feed or soil conditioner.

-

Environmental Solutions: Neutralizing acidic waste or removing heavy metals from industrial runoff.

-

-

For Magnesium Oxide Board Manufacturers:

MgO boards serve numerous construction and building applications:-

Residential & Commercial Buildings: Wall panels, ceilings, and flooring with fire-resistant properties.

-

Public & Institutional Spaces: Fire-rated partitions in schools, hospitals, and offices.

-

Modular & Prefabricated Housing: Lightweight, durable, and eco-friendly panels.

-

Specialized Projects: Decorative or structural uses in green building initiatives.

-

-

Why Range Matters:

A broader application spectrum indicates that the MGO company understands different industry needs and can provide tailored solutions. For example, a supplier experienced in both raw MgO and boards can ensure that materials are optimized for specific fire ratings or industrial performance.

In essence, evaluating the range of applications gives insight into the capabilities, expertise, and versatility of an MGO company. Companies that can serve multiple industries are more likely to offer reliable and innovative solutions for your project needs.

4. Global Export Experience

An important consideration when selecting an MGO company is its global export experience. Companies with international reach demonstrate reliability, compliance with regulations, and the ability to handle logistics efficiently.

-

For MgO Powder Suppliers:

Exporting raw magnesium oxide requires familiarity with chemical shipping regulations, proper packaging, and documentation for international standards. Companies with global experience are more capable of delivering consistent quality across borders, whether supplying powder for steel, agriculture, or chemical applications. Their established networks reduce the risk of delays or shipment issues. -

For MgO Board Manufacturers:

Exporting boards involves additional challenges, including safe packaging to prevent moisture or damage, compliance with fire safety standards in different countries, and timely delivery to construction sites. Companies experienced in international markets understand the specific requirements of various regions, ensuring boards meet local building codes and certifications. -

Why It Matters:

A company’s export history reflects its operational reliability and ability to support long-term projects. For buyers, working with an MGO company that has successfully supplied both MgO raw materials and boards worldwide offers confidence in consistent delivery and adherence to international quality standards. -

Additional Benefits:

Global experience often comes with knowledge of market trends, currency fluctuations, and shipping solutions. It also indicates that the company has maintained strong client relationships, which is a positive indicator of trustworthiness.

In short, choosing an MGO company with proven global export experience helps mitigate risks, ensures smooth supply chains, and provides access to both raw MgO and finished boards for worldwide projects.

5. Customer Support and Technical Assistance

Reliable customer support and technical assistance are essential when choosing an MGO company, whether you are sourcing raw magnesium oxide or magnesium oxide boards. Excellent support can save time, reduce errors, and ensure your project meets its performance goals.

-

For MgO Powder Suppliers:

Technical guidance on chemical composition, particle size, and suitable applications is crucial. Experienced suppliers help clients select the right grade of MgO for steelmaking, refractory applications, agriculture, or chemical processing. They may provide lab test results, dosage recommendations, and troubleshooting tips to maximize efficiency and reduce waste. -

For MgO Board Manufacturers:

Support often includes installation instructions, construction guidance, and post-installation assistance. This ensures boards are correctly mounted, maintaining fire resistance, durability, and dimensional stability. Some companies even offer on-site training or customized solutions for unique architectural designs or large-scale projects. -

Why It Matters:

Even high-quality products can underperform without proper technical guidance. Companies that provide professional support help clients avoid costly mistakes, improve material performance, and achieve better project outcomes. -

Building Long-Term Partnerships:

Responsive customer service reflects a company’s commitment to long-term collaboration. When technical assistance is readily available, buyers can confidently scale projects, experiment with new applications, or adapt materials to specific requirements.

In conclusion, customer support and technical assistance are more than just services—they are critical indicators of an MGO company’s professionalism, reliability, and commitment to client success.

6. Sustainability and Environmental Commitment

In today’s construction and industrial sectors, sustainability is a critical factor when evaluating an MGO company. Companies that prioritize environmental responsibility not only help protect the planet but also offer long-term benefits to clients seeking eco-friendly solutions.

-

For MgO Powder Suppliers:

Sustainable production involves energy-efficient calcination, waste reduction, and responsible mining practices. Low-carbon processes reduce greenhouse gas emissions and minimize the environmental impact of raw material extraction. Suppliers that invest in greener technology demonstrate a commitment to both quality and environmental stewardship. -

For MgO Board Manufacturers:

Boards made from MgO are inherently eco-friendly, as they are recyclable, non-toxic, and free from harmful chemicals. Leading manufacturers adopt production techniques that reduce energy consumption, minimize chemical residues, and ensure boards meet environmental certifications. This makes MgO boards a preferred choice for green building projects and sustainable construction. -

Why It Matters:

Choosing a company with strong environmental standards ensures compliance with increasingly strict regulations and supports corporate sustainability goals. It also reflects a long-term commitment to responsible production, which can enhance brand reputation and market competitiveness. -

Future-Oriented Practices:

Many forward-thinking MGO companies are exploring renewable energy use, water-saving processes, and closed-loop recycling. These innovations further reduce the environmental footprint of both MgO powder and boards, aligning with global sustainability trends.

In summary, evaluating an MGO company’s sustainability practices is essential. A company that balances high-quality production with environmental responsibility provides products that are not only reliable but also support greener, safer, and more sustainable projects.

Case Study: Suparna as a Trusted MGO Company

Suparna is a leading MGO company that exemplifies the combination of high-quality magnesium oxide raw materials and superior MgO board supply.

-

Excellence in Raw Materials:

Suparna produces high-purity MgO powders, including light-burned and dead-burned grades. These products are widely used in refractory materials, industrial processes, agriculture, and environmental applications. Suparna ensures consistent chemical composition, particle size, and stability, giving clients confidence in their supply chain. -

Strength in MgO Boards:

Suparna’s MgO boards are designed for fire safety, durability, and eco-friendliness. The boards meet international fire ratings and exhibit excellent resistance to bending, cracking, and moisture. Available in various thicknesses and sizes, they are suitable for walls, ceilings, floors, and modular construction projects. -

Global Reach and Export Experience:

Suparna exports both MgO powders and boards to multiple continents, demonstrating strong logistics, compliance with international regulations, and experience in serving diverse markets. Their reliable supply chain ensures timely deliveries, reducing project delays and supporting long-term partnerships. -

Sustainability and Innovation:

Committed to environmentally responsible practices, Suparna uses energy-efficient production methods and recyclable materials. Their MgO boards are non-toxic and safe for indoor environments, aligning with green building initiatives and sustainable construction goals.

By combining premium raw materials, advanced manufacturing, technical support, and sustainability, Suparna serves as a model MGO company. Clients benefit from both high-quality products and a trustworthy partner capable of meeting complex industrial and construction needs.

How to Make Smarter Decisions When Choosing an MGO Company

Selecting the right MGO company requires careful evaluation across multiple factors. Whether you are sourcing magnesium oxide powders or MgO boards, a strategic approach ensures reliability, quality, and project success.

-

Assess Product Quality and Consistency

Verify chemical composition, MgO content, and mechanical properties. Request certifications and test reports to ensure every shipment meets international standards. -

Evaluate Production Capacity and Technology

Check whether the company can handle your required volume and maintain consistent quality. Modern production lines and advanced technologies indicate efficiency, reliability, and lower defect rates. -

Consider the Range of Applications

A versatile MGO company can support multiple industries and project types. For raw MgO, this means applications in steel, refractories, and chemicals. For boards, it includes walls, ceilings, floors, and modular construction. -

Examine Global Export Experience

Companies experienced in international trade understand packaging, shipping, and compliance requirements. This reduces risks, ensures timely delivery, and guarantees adherence to local standards. -

Check Customer Support and Technical Assistance

Reliable technical support helps you optimize material selection and installation. Whether guidance on powder applications or board mounting instructions, professional support prevents mistakes and enhances performance. -

Review Sustainability Practices

Companies committed to eco-friendly production and recyclable materials contribute to long-term environmental and corporate goals. Sustainable practices also signal forward-thinking management and operational efficiency.

Actionable Tip: Create a checklist based on these six factors before reaching out to suppliers. Request samples, verify certifications, and assess the company’s responsiveness. A well-prepared selection process minimizes risk and ensures your project benefits from high-quality MgO products.

By following these steps, you can make smarter decisions when choosing an MGO company—one that provides reliable raw materials, superior boards, and long-term partnership value.

Conclusion

Choosing the right MGO company is a critical decision that affects project quality, safety, and cost efficiency. Whether you are sourcing magnesium oxide powder for industrial processes or MgO boards for fire-resistant construction, selecting a reliable and experienced supplier ensures consistent performance and minimizes risks.

Throughout this guide, we’ve highlighted the importance of evaluating six key factors: product quality and consistency, production capacity and technology, range of applications, global export experience, customer support, and sustainability practices. Companies that excel in these areas provide not only superior materials but also peace of mind for long-term projects.

A trusted MGO company becomes more than a supplier—it is a partner that helps you achieve durable, safe, and environmentally responsible solutions. From ensuring high-purity raw materials to delivering boards that meet stringent fire ratings, the right choice can significantly enhance both operational efficiency and project outcomes.

Ready to source high-quality MgO products or boards? Contact Suparna today to explore premium solutions, request samples, and receive expert technical guidance tailored to your specific needs. Make a smart choice and ensure your projects succeed with the support of a dependable MGO company.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

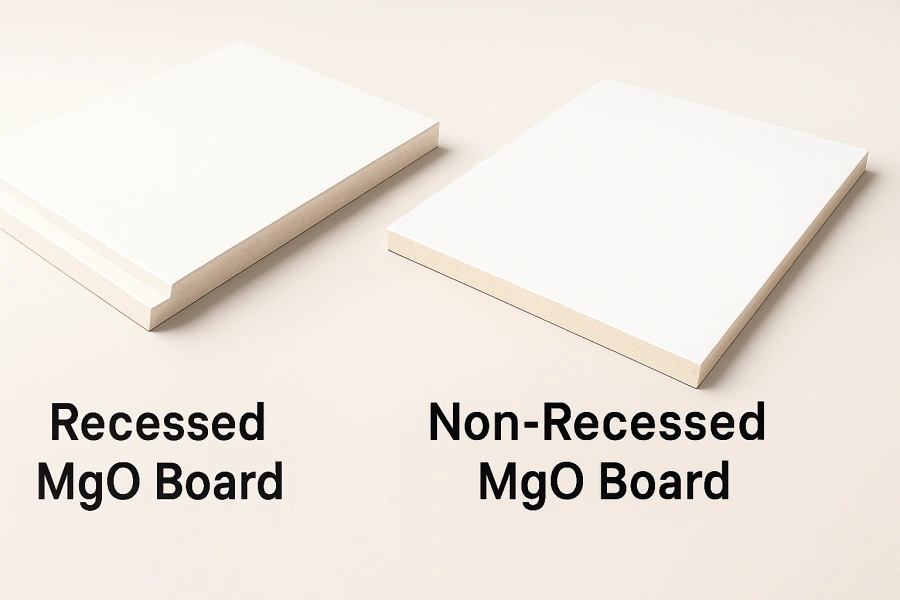

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

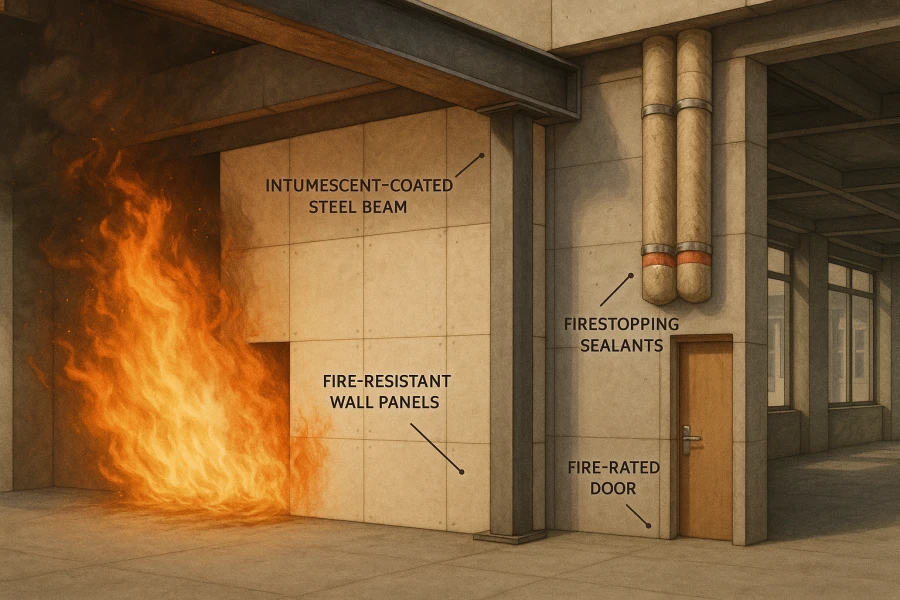

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.