Table of Contents

Ask Us Any Question

Introduction to MGO Boards

What is an MGO Board?

Magnesium Oxide Board, commonly referred to as MGO board, is a high-performance building material widely used in modern construction. Made primarily from magnesium oxide, magnesium chloride, and other additives, MGO boards are renowned for their fire resistance, moisture resistance, and durability. Unlike traditional gypsum boards or cement boards, MGO boards offer a unique combination of strength and lightweight properties, making them suitable for a wide range of applications including walls, ceilings, flooring, and external cladding.

The manufacturing process ensures a dense and uniform panel that can withstand high temperatures, resist mold, and remain structurally stable over time. For builders, designers, and contractors, understanding the characteristics of MGO boards—including mgo board weight—is crucial for safe installation, structural planning, and logistics.

Key Features of Magnesium Oxide Boards

MGO boards stand out for several reasons:

-

Fire Resistance: MGO boards can withstand high temperatures without combusting, making them ideal for fire-safe construction.

-

Moisture and Mold Resistance: Unlike gypsum boards, MGO boards do not absorb water easily, reducing the risk of mold or warping.

-

Durability: The boards are hard and impact-resistant.

-

Eco-Friendly Material: Made from non-toxic materials, MGO boards are environmentally friendly and safe for indoor air quality.

-

Lightweight: Despite their durability, MGO boards are relatively light, which simplifies handling and installation—but the exact weight can vary depending on size and thickness.

Understanding these features sets the stage for discussing MGO board weight, which is often a key concern for builders when calculating load-bearing requirements and ease of installation.

Understanding MGO Board Weight

Typical Weight per Square Meter / Sheet

The weight of an MGO board is one of its most important characteristics, as it affects handling, transportation, and structural planning. Generally, the weight depends on the board’s thickness, density, and dimensions.

-

Standard Sizes: Most MGO boards come in dimensions like 1220mm × 2440mm (4ft × 8ft).

-

Common Thicknesses: 6mm, 8mm, 10mm, 12mm, and 15mm.

-

Typical Weight Ranges:

-

6mm board: Approximately 17–18 kg per sheet

-

8mm board: Approximately 23–24 kg per sheet

-

10mm board: Approximately 29–30 kg per sheet

-

12mm board: Approximately 35–36 kg per sheet

-

15mm board: Approximately 44–45 kg per sheet

-

For reference, in weight per square meter, MGO boards generally range from 7 to 12 kg/m², depending on thickness and additives used. Builders often need this information to calculate load distribution, especially for ceiling installations or suspended walls.

Factors Affecting Board Weight (Thickness, Density, Size)

Several factors influence the actual weight of an MGO board:

-

Thickness: Thicker boards naturally weigh more. A 12mm board can weigh nearly double a 6mm board of the same size.

-

Density: Manufacturing processes and raw material ratios affect the density of the board. Higher-density boards are heavier but offer slightly better impact resistance.

-

Board Size: While 1220mm × 2440mm is standard, customized boards may vary in size, altering their total weight.

-

Additives and Reinforcements: Some MGO boards include fiberglass mesh, perlite, or other fillers to enhance performance. These additions slightly increase weight.

Understanding these factors helps contractors choose the right board for their specific construction needs while optimizing transportation and installation efforts.

Weight Comparison with Other Common Boards (Gypsum, Cement, Plywood)

When planning construction projects, it is helpful to compare MGO boards with alternative materials:

| Board Type | Typical Weight per m² | Fire Resistance | Moisture Resistance |

|---|---|---|---|

| MGO Board (10mm) | 9–12 kg | High | High |

| Gypsum Board (10mm) | 7–9 kg | Medium | Low |

| Cement Board (10mm) | 18–20 kg | High | Medium |

| Plywood (10mm) | 6–8 kg | Low | Low–Medium |

From this comparison, MGO boards offer a balanced solution: they are lighter than cement boards yet stronger and more moisture-resistant than gypsum boards. This makes them an attractive choice for applications where weight, fire safety, and durability are all critical factors.

Applications and How Weight Matters

Flooring

When used for flooring, the weight of an MGO board plays a critical role. Lighter boards are easier to handle, reducing labor costs and installation time. Heavier boards, however, can provide better stability and sound insulation. In residential or commercial flooring applications, boards of 18–20mm thickness are commonly chosen, balancing weight and durability. Properly calculating the weight is essential to ensure the subfloor can safely support the load without risk of sagging or structural damage.

Wall Cladding

For wall applications, MGO boards are often preferred over traditional gypsum boards due to their fire resistance and moisture resistance. Weight is an important consideration when installing boards on high walls or in multi-story buildings. Lighter boards simplify the installation process, especially for ceilings and upper walls, whereas heavier boards provide a more solid feel and can improve impact resistance. Fastening systems and wall framing must account for board weight to maintain safety and stability.

Ceilings and Partitions

Ceilings and partition walls are highly sensitive to material weight. Using lightweight MGO boards for suspended ceilings can reduce the load on support structures while maintaining fireproofing standards. For partitions, the weight of the boards influences wall rigidity, ease of handling, and overall labor efficiency. Builders often prefer boards around 8–12mm for partitions to ensure ease of installation without sacrificing durability.

Transport and Handling Considerations

The weight of MGO boards also affects logistics and handling:

-

Transportation: Knowing the exact weight per sheet or per pallet is critical for planning shipments, avoiding overloading vehicles, and reducing transportation costs.

-

Storage: Heavy boards require proper stacking to prevent bending or warping.

-

On-Site Handling: Lighter boards reduce physical strain for workers and allow faster installation, while heavier boards may need additional support equipment.

In all applications, understanding MGO board weight ensures efficiency, safety, and cost-effectiveness, helping builders and contractors select the right board for the right purpose.

Benefits of Knowing MGO Board Weight

Ease of Installation

Knowing the weight of MGO boards allows builders to plan installation more efficiently. Lighter boards are easier to carry, position, and fix, reducing the physical strain on workers and the risk of accidents. When teams are aware of weight variations between different thicknesses or sizes, they can choose the appropriate handling methods or tools, such as lifts, trolleys, or scaffolding, ensuring a smoother installation process.

Structural Safety and Load Planning

Accurate weight information is essential for structural safety. Engineers and architects must consider the cumulative weight of all boards in walls, ceilings, or flooring to prevent structural overload. Overestimating or underestimating board weight can lead to compromised stability or costly reinforcement measures. By knowing the exact MGO board weight, designers can make informed decisions about framing, support spacing, and load-bearing capacities.

Cost Implications

The weight of MGO boards also impacts the overall project cost. Heavier boards increase transportation costs due to higher shipping weight and may require additional labor or equipment for installation. Conversely, using boards that are too light for certain applications might lead to increased maintenance or early replacement costs. Understanding the weight allows contractors to balance durability, cost, and performance efficiently.

Understanding the weight of MGO boards provides tangible benefits in installation efficiency, safety, and cost management, making it a critical consideration for every construction project.

Tips for Choosing the Right MGO Board Based on Weight

Standard Sizes and Weights

When selecting an MGO board, it’s important to understand the standard sizes and corresponding weights. Most boards come in 1220mm × 2440mm (4ft × 8ft) sheets, with thicknesses ranging from 6mm to 15mm. The typical weight ranges are:

-

6mm: 18 kg per sheet

-

8mm: 24 kg per sheet

-

10mm: 30 kg per sheet

-

12mm: 36 kg per sheet

-

15mm: 45 kg per sheet

Selecting the correct thickness helps balance weight, strength, and ease of installation. Lighter boards are ideal for ceilings or partitions, while heavier boards may be preferable for flooring or high-impact areas.

Lightweight vs Heavier Boards: Pros and Cons

Understanding the trade-offs between lightweight and heavier MGO boards helps in making the best choice for your project:

-

Lightweight Boards:

-

Easier to transport and install

-

Reduce labor costs

-

Ideal for ceilings, partitions, or DIY projects

-

May have slightly lower impact resistance

-

-

Heavier Boards:

-

Provide better stability and sound insulation

-

Suitable for flooring, external walls, or high-traffic areas

-

Require more labor and careful handling

-

Increased transportation cost

-

Choosing the right balance ensures that the board meets the structural, fire safety, and budgetary requirements of your project.

Recommendations for Different Construction Needs

-

Ceilings & Partitions: 6–10mm lightweight boards

-

Walls & Cladding: 10–12mm boards for stability and durability

-

Flooring & High Impact Areas: 18–20mm heavier boards

-

Transport Considerations: Always calculate pallet weight and site handling capacity

By matching board weight to the specific construction application, you can optimize performance, reduce risk, and save costs while maintaining high fire safety standards.

Conclusion

Understanding the weight of MGO boards is essential for anyone involved in construction, whether you are a builder, architect, or project manager. The weight affects installation efficiency, structural safety, cost, and transportation logistics. By knowing the typical weights, factors influencing weight, and how different board sizes and thicknesses perform, you can make informed decisions that enhance both safety and efficiency on your projects.

When choosing the right MGO board, consider:

-

The specific application (flooring, walls, ceilings, partitions)

-

The thickness and size of the board

-

The balance between ease of handling and structural requirements

Selecting the proper board not only ensures compliance with fire safety standards but also improves installation speed, reduces labor costs, and minimizes potential risks.

If you want expert guidance on selecting the ideal MGO board for your project or need detailed weight specifications for bulk orders, contact Suparna MgO Board today. Our team of specialists can provide personalized advice and ensure you choose the right board for optimal performance, safety, and efficiency.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

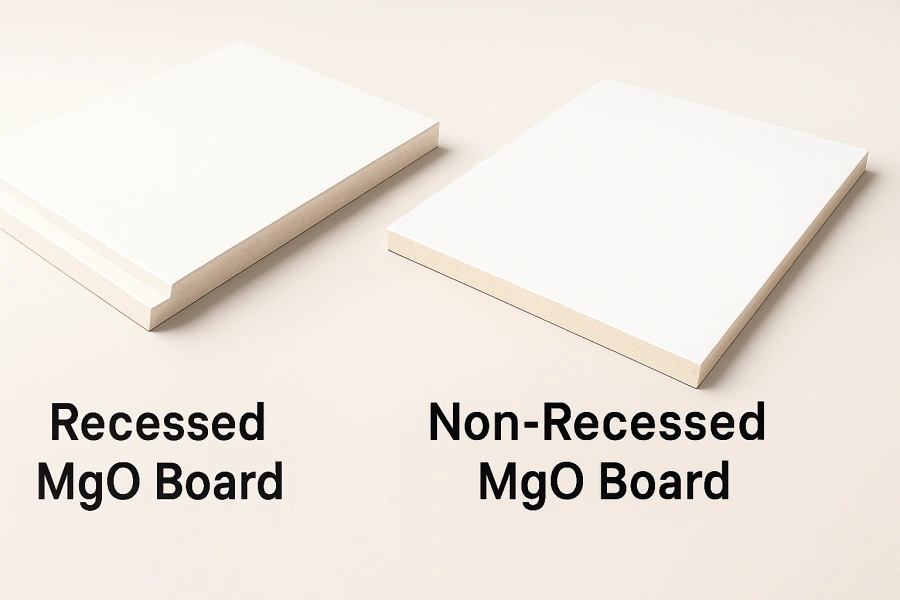

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

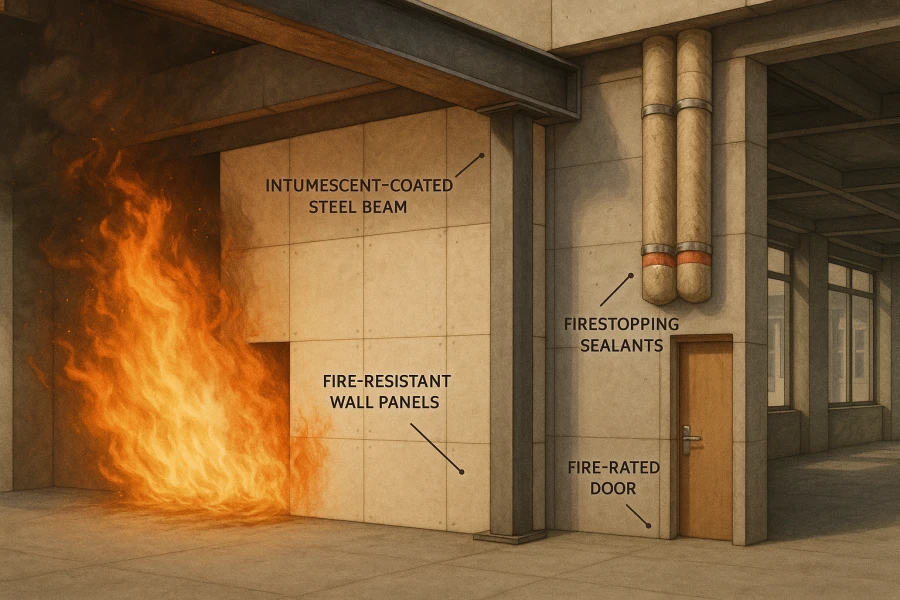

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.