Table of Contents

Ask Us Any Question

Introduction

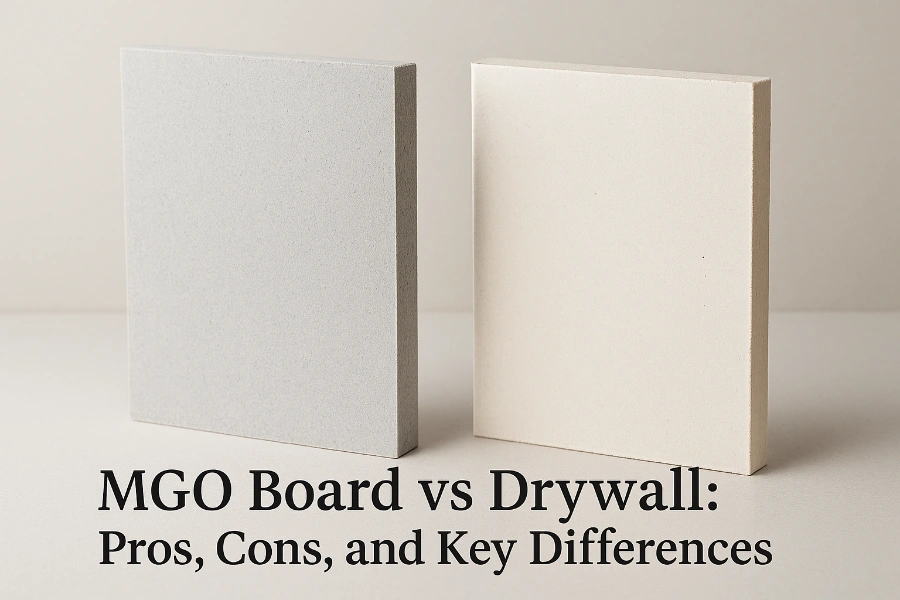

In modern construction and interior design, selecting the right wall material is crucial for durability, safety, and overall performance. Two of the most commonly used options are MGO board and drywall. Each material has unique properties, advantages, and limitations that influence its suitability for different projects.

MGO board is a mineral-based panel known for its fire resistance, moisture tolerance, and structural strength. It has been widely adopted in areas where safety and longevity are priorities. On the other hand, drywall, also called gypsum board, has been a staple in residential and commercial construction due to its lightweight nature, ease of installation, and cost-effectiveness.

Comparing MGO board vs drywall helps architects, builders, and homeowners make informed decisions based on the specific demands of their projects. Factors such as fire safety, moisture exposure, durability, and installation convenience are key considerations. Understanding the pros and cons of each material ensures that the chosen solution meets both performance requirements and budget constraints.

What is MGO Board

Composition and Structure

MGO board, or magnesium oxide board, is a high-performance construction panel made from magnesium oxide, magnesium chloride, and reinforcing fibers. These materials are blended, pressed, and cured to create rigid panels that offer structural strength beyond what typical drywall provides. Some boards incorporate fiberglass mesh or other additives to enhance durability and reduce cracking.

The dense composition of MGO boards not only gives them mechanical stability but also contributes to their fire-resistant and moisture-resistant properties. They can be manufactured in various thicknesses and densities, making them suitable for walls, ceilings, and other structural applications.

Key Advantages

MGO board provides several benefits that make it a popular choice in construction:

-

Fire resistance – the panels are inherently non-combustible, making them ideal for areas where fire safety is a priority.

-

Moisture resistance – MGO board maintains its shape and performance even in humid environments, unlike drywall which can warp or develop mold.

-

Environmental friendliness – produced from abundant natural minerals, MGO boards contain no harmful VOCs and are often considered a greener building material.

-

Strength and durability – the dense structure allows for impact resistance and long-term stability, making walls and ceilings more robust.

Potential Drawbacks

Despite these advantages, there are a few considerations:

-

Cost – MGO boards are generally more expensive than drywall, which can influence project budgets.

-

Corrosion risk – untreated magnesium chloride-based MGO boards can accelerate corrosion of metal components if not properly protected, especially in contact with steel fasteners in humid area.

-

Weight – the density that gives MGO board strength also makes it heavier, requiring more effort during handling and installation compared with lightweight drywall.

Overall, MGO board is a high-performance alternative to conventional drywall, offering superior fire safety, moisture resistance, and durability, though it requires careful handling and consideration of cost.

What is Drywall

Composition and Structure

Drywall, also known as gypsum board, is a widely used wall and ceiling material made primarily from gypsum, a soft sulfate mineral, sandwiched between two layers of heavy paper. It comes in various thicknesses and sizes, with specialty types available for fire resistance, moisture resistance, or soundproofing. The lightweight panels make handling and cutting easier compared with denser boards like MGO.

Drywall is typically installed by screwing or nailing the panels to a wooden or metal frame. Joints are filled with compound, and surfaces are often finished with paint or wallpaper, providing flexibility in interior design. Its composition and installation simplicity have made it the standard choice in many residential and commercial projects.

Key Advantages

Drywall offers several practical benefits:

-

Lightweight – easy to transport, handle, and install, reducing labor effort.

-

Easy to work with – panels can be cut, drilled, or shaped on site with basic tools.

-

Cost-effective – generally more affordable than MGO board, making it suitable for budget-conscious projects.

-

Fast installation – can cover large areas quickly, which is advantageous in large-scale renovations or new constructions.

Potential Drawbacks

While drywall has its strengths, it also has limitations:

-

Limited fire resistance – standard drywall offers some protection but is far less fire-resistant than MGO board.

-

Vulnerable to moisture – exposure to water can cause swelling, warping, and mold growth.

-

Lower durability – drywall is more susceptible to dents, cracks, and impact damage compared with denser panels.

Drywall remains a versatile, economical choice for many interior applications, especially where fire resistance and long-term durability are not critical requirements.

Head-to-Head Comparison: MGO Board vs Drywall

Fire Resistance

MGO board excels in fire resistance due to its mineral composition. It is non-combustible and can withstand high temperatures without losing structural integrity, making it suitable for areas with strict fire safety requirements. Drywall, while offering moderate fire resistance—especially fire-rated types—cannot match the performance of MGO boards in high-risk environments. This makes MGO a preferred option for commercial buildings, kitchens, or areas near heat sources.

Moisture Resistance

One of the key advantages of MGO board is its ability to resist moisture. It does not warp, swell, or support mold growth under humid conditions. In contrast, standard drywall can deteriorate quickly when exposed to water, leading to swelling, softening, or mold problems. Moisture-resistant drywall variants exist, but they still do not achieve the same long-term stability as MGO boards in wet environments.

Durability and Strength

MGO board is significantly stronger and more impact-resistant than drywall. Its dense composition allows it to withstand bumps, knocks, and everyday wear without easily cracking. Drywall, being lightweight and less rigid, is prone to dents, cracks, and damage from impact. For areas subject to heavy use or potential mechanical stress, MGO provides longer-lasting performance.

Environmental Impact

MGO boards are considered environmentally friendly, made from abundant natural minerals and free of harmful volatile organic compounds (VOCs). Drywall production involves gypsum mining and paper processing, and while some recycled materials are used, it generally has a higher environmental footprint than MGO boards, especially when considering durability and replacement frequency.

Cost and Installation

Drywall is lighter and easier to handle, which reduces labor costs and speeds up installation. Its material cost is also lower than MGO board, making it a more economical choice for budget-conscious projects. MGO board, while more expensive and heavier, provides benefits that may offset its initial cost in terms of longevity, safety, and reduced maintenance over time.

Aesthetic Flexibility

Both materials can be finished with paint, wallpaper, or veneer. Drywall offers smooth surfaces that are easy to customize quickly. MGO board, due to its strength and rigidity, allows for a wider range of surface treatments including tiling, cladding, or textured finishes without compromising durability. This makes it suitable for both functional and decorative applications.

Ideal Applications for Each Material

MGO board and drywall serve different purposes depending on the environmental conditions, building requirements, and performance expectations. Understanding where each material excels helps in making an informed choice.

MGO Board Applications

MGO board is particularly suitable for environments where fire safety, moisture resistance, and durability are critical:

-

Commercial buildings, hotels, and public spaces where fire codes are strict.

-

Kitchens, bathrooms, or basements where humidity can damage ordinary drywall.

-

Industrial facilities or laboratories where impact resistance and structural stability are required.

-

High-end residential projects where longevity and minimal maintenance are priorities.

-

Areas needing surface finishes like tiling or cladding without risking board damage.

Drywall Applications

Drywall is ideal for settings where cost, speed, and ease of installation are the main priorities:

-

Residential interior walls and ceilings, especially in bedrooms, living rooms, and hallways.

-

Office spaces or commercial renovations where quick installation is important.

-

Temporary partitions or areas with low exposure to fire, moisture, or heavy impact.

-

Projects with tight budgets where lightweight materials simplify transportation and installation.

By selecting the right material for the appropriate context, builders and designers can optimize both performance and cost-effectiveness, ensuring a balance between safety, durability, and aesthetic flexibility.

Conclusion

When comparing MGO board and drywall, it is clear that each material has its strengths and limitations. MGO board stands out for its fire resistance, moisture tolerance, and long-term durability, making it suitable for high-risk, high-performance, or high-end construction projects. Its higher cost and heavier weight, along with potential corrosion risks if untreated, are factors that need to be considered during planning and installation.

Drywall, in contrast, offers cost-effectiveness, lightweight handling, and quick installation, making it ideal for standard residential interiors or projects with tight budgets. However, it is less resistant to fire and moisture and may require more frequent maintenance or replacement in demanding environments.

Ultimately, the choice between MGO board and drywall depends on the specific needs of the project, including safety requirements, environmental conditions, and long-term performance expectations. For projects that demand fire-safe, durable, and moisture-resistant walls, MGO board is a reliable choice. For cost-sensitive applications where ease of installation is a priority, drywall remains a practical solution.

For more detailed guidance and professional recommendations on choosing the right wall material for your project, contact our team. We can help you select the best solution tailored to your construction requirements, ensuring safety, efficiency, and quality in every build.

Explore the best heat proof and heat resistant materials for safer construction. Learn their benefits, applications, and safety advantages.

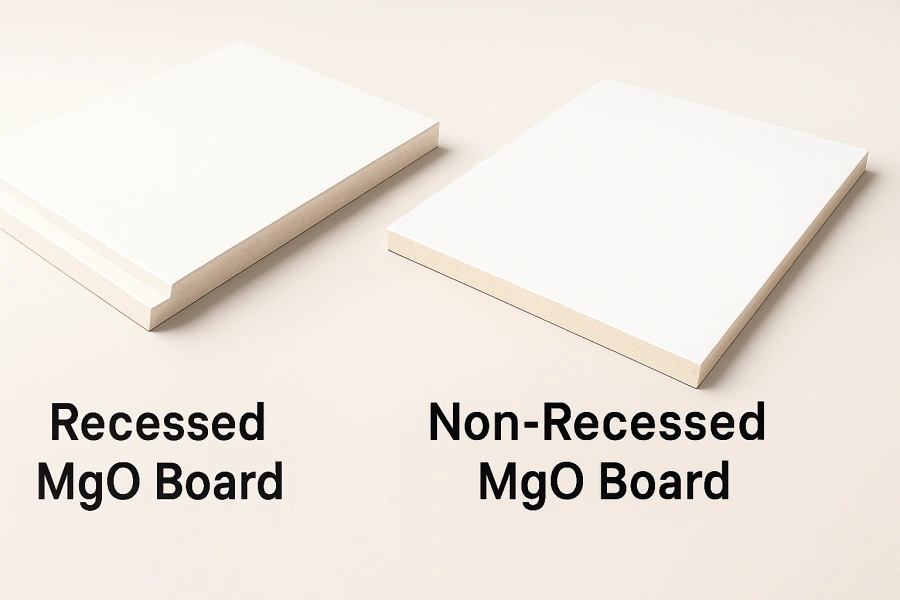

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Compare MgSO4 board vs MgCl2 board: discover key differences, performance, and durability to choose the best mgo board for your project.