Table of Contents

Ask Us Any Question

Introduction

In today’s construction industry, builders and homeowners are constantly comparing MgO board vs cement board when choosing the right substrate or wall panel. Both materials are widely recognized for their strength and durability, but they serve slightly different purposes depending on the project. While MgO board, also called magnesium oxide board, is known for its excellent fire resistance and eco-friendly profile, cement board is often favored for tile backing and wet area applications.

Understanding the difference between MgO panel vs cement panel can save both time and cost in your construction project. In this article, we will break down 7 key differences between the two materials so you can make an informed decision.

What Is MgO Board?

Magnesium oxide board, commonly referred to as MgO board, is a next-generation building material made from magnesium oxide, perlite, fiberglass mesh, and other natural additives. It is engineered to deliver exceptional performance in areas where traditional gypsum or cement boards may fall short.

MgO boards are lightweight yet strong, offering Class A1 fire resistance, moisture resistance, and mold prevention. These qualities make them a preferred choice for interior walls, ceilings, flooring underlayment, and fire-rated partitions. Compared with cement boards, MgO boards are easier to cut and install, reducing labor costs on site.

When discussing mgo board vs cement board, it is important to note that MgO boards are also eco-friendly. They do not contain asbestos, formaldehyde, or other harmful chemicals. This makes them attractive for projects focused on sustainability and indoor air quality.

From another angle, many buyers and architects use the term mgo panel vs cement panel interchangeably with “board.” In both cases, MgO panels stand out for their versatility, making them suitable not only for residential projects but also for commercial buildings that demand higher safety and performance standards.

What Is Cement Board?

Cement board is a traditional construction material made from Portland cement reinforced with fiberglass mesh. It is designed to provide a stable, water-resistant base, making it especially popular as a backing material for tiles in bathrooms, kitchens, and other wet areas. Unlike regular drywall, cement boards do not easily disintegrate when exposed to moisture, which is why contractors often recommend them for areas that need extra durability.

When comparing mgo board vs cement board, one major difference lies in weight and handling. Cement boards are generally heavier and more rigid, which can make installation more labor-intensive. However, this density also contributes to their strength, making them highly impact-resistant and a solid choice for floors and exterior wall sheathing.

The term mgo panel vs cement panel often arises in project discussions. While cement panels share the same moisture- and mold-resistant benefits, they usually lack the superior fire rating and eco-friendly advantages of MgO panels. Still, cement boards are a reliable option where cost control and proven performance are the top priorities, especially in tile-heavy applications.

7 Key Differences Between MgO Board and Cement Board

1. Fire Resistance

One of the most significant differences in the mgo board vs cement board comparison is fire performance. MgO boards are classified as A1 non-combustible, which means they can withstand extremely high temperatures without releasing toxic smoke. This makes them ideal for use in fire-rated walls, partitions, and flooring systems where safety is a top priority.

Cement boards, while also fire-resistant, do not reach the same level of performance. They can protect against flames to a certain extent, but under prolonged exposure to high heat, cement boards may eventually crack or degrade. This difference becomes critical in commercial buildings, schools, and residential projects that must comply with strict fire safety codes.

For architects and contractors considering mgo panel vs cement panel, MgO panels clearly stand out when fire protection is a key requirement. Choosing MgO board not only enhances occupant safety but can also help meet insurance and building regulation standards more easily.

2. Moisture & Mold Resistance

Another major factor in the mgo board vs cement board debate is how each material performs in damp or humid environments. MgO boards are naturally resistant to moisture because of their magnesium oxide composition. They do not swell, warp, or break down easily when exposed to water. In addition, their alkaline nature helps prevent mold and mildew growth, making them an excellent choice for basements, kitchens, bathrooms, and even exterior applications.

Cement boards are also designed for wet areas, and that is why they are commonly used as tile backer boards in showers and laundry rooms. However, they can be heavier and more difficult to handle, and over time, if not properly sealed, they may still absorb moisture. This can slightly compromise performance in extreme humidity.

When comparing mgo panel vs cement panel, MgO panels usually provide longer-lasting protection against water damage and fungal growth. This added resilience often makes them the preferred solution in projects where both structural stability and indoor air quality are priorities.

3. Strength & Durability

When discussing mgo board vs cement board, strength and durability are always key considerations. MgO boards are lightweight yet remarkably strong. Their composition gives them excellent flexural strength, meaning they can withstand bending and impact without cracking easily. This makes them suitable not only for interior walls and ceilings but also for flooring underlayment where foot traffic is high.

Cement boards, on the other hand, are known for their dense and rigid structure. They are highly impact-resistant, which makes them a dependable option for floors, tile backers, and external sheathing. However, their rigidity can sometimes be a disadvantage, as they are more prone to cracking during installation or if the structure shifts slightly.

When comparing mgo panel vs cement panel, MgO panels often have the advantage of combining durability with flexibility. They resist chipping and damage during handling, while cement panels tend to be heavier and less forgiving. For builders seeking long-term stability with easier installation, MgO panels typically prove to be the more versatile option.

4. Weight & Ease of Installation

One of the practical differences in the mgo board vs cement board discussion is weight and how easy each material is to work with. MgO boards are significantly lighter than cement boards, which makes them easier to lift, cut, and install on-site. Contractors can use standard woodworking tools to cut MgO panels, reducing both labor time and tool wear. This efficiency can be a big advantage in large-scale projects where speed and handling matter.

Cement boards, by contrast, are heavier and denser. While this adds to their strength, it also means more effort is required during transport and installation. Cutting cement panels often requires specialized tools, and the dust generated during the process can be messy and hazardous without proper protection.

When comparing mgo panel vs cement panel, MgO panels clearly win in terms of installation convenience. Their lighter weight and cleaner cutting process not only improve working conditions but also help reduce overall labor costs. For teams working under tight schedules, MgO board often proves to be the smarter choice.

5. Environmental Impact

In today’s eco-conscious construction industry, the environmental footprint of building materials is a crucial consideration in the mgo board vs cement board debate. MgO boards are highly sustainable: they are manufactured from natural minerals, require lower energy consumption during production, and do not emit harmful chemicals such as formaldehyde or asbestos. This makes MgO panels an ideal choice for green building certifications and projects that prioritize indoor air quality.

Cement boards, while durable and reliable, typically have a higher environmental impact. The production of Portland cement consumes significant energy and produces CO₂ emissions, contributing to a larger carbon footprint. While cement panels are recyclable, their environmental performance does not match that of MgO panels in terms of sustainability and eco-friendliness.

When considering mgo panel vs cement panel, MgO panels clearly lead in environmental benefits. Choosing MgO boards can help architects and developers meet sustainability goals without compromising performance, making them a more responsible long-term investment.

👉️ Check the safety test reports (formaldehyde, asbestos, VOC) of Suparna MgO Board

6. Cost Comparison

Cost is often a decisive factor when comparing mgo board vs cement board. MgO boards tend to have a higher upfront cost due to their advanced manufacturing process and superior performance features. However, this initial investment can be offset by lower labor costs, faster installation, and reduced maintenance over time. MgO panels’ durability and resistance to fire, moisture, and mold can save money in repairs and replacements.

Cement boards are generally more affordable initially, which makes them attractive for budget-conscious projects. However, their heavier weight and the need for specialized cutting tools can increase labor expenses. Additionally, if used in high-moisture or high-fire-risk areas, cement panels may require extra protective measures, adding to long-term costs.

When evaluating mgo panel vs cement panel, it’s clear that MgO panels offer better overall value for projects where safety, sustainability, and ease of installation are priorities. For long-term performance, the slightly higher price often pays off in reduced maintenance and enhanced building longevity.

7. Versatility in Applications

Versatility is another key factor in the mgo board vs cement board comparison. MgO boards are incredibly adaptable and can be used in a wide range of applications. They are suitable for interior walls, ceilings, flooring underlayment, fire-rated partitions, and even exterior facades. Their combination of light weight, strength, and fire resistance allows architects and builders to explore creative designs without compromising safety or durability.

Cement boards, while strong and moisture-resistant, are typically limited to specific uses such as tile backing, wet area walls, or exterior sheathing. They excel in heavy-duty applications but do not offer the same flexibility in design as MgO panels.

When comparing mgo panel vs cement panel, MgO panels clearly provide more options for modern construction projects. Whether it’s a residential renovation or a commercial building, MgO panels can meet multiple requirements with a single material, simplifying procurement and installation.

Which One Should You Choose?

Choosing between mgo board vs cement board ultimately depends on your project requirements. If fire resistance, moisture protection, lightweight handling, and environmental sustainability are top priorities, MgO boards are the smarter choice. They are ideal for residential interiors, commercial spaces, and areas requiring high safety standards.

Cement boards, on the other hand, are well-suited for budget-conscious projects where heavy-duty strength and wet-area performance are the main concerns, such as tile backing in bathrooms and kitchens. However, the heavier weight and limited flexibility of cement panels may require more labor and time during installation.

Considering mgo panel vs cement panel, MgO panels are generally more versatile, offering multiple applications without compromising performance. This makes them a preferred choice for modern construction projects that aim for efficiency, safety, and sustainability.

Conclusion & Call to Action

In summary, the 7 key differences between MgO board and cement board — fire resistance, moisture & mold resistance, strength, weight, environmental impact, cost, and versatility — highlight why MgO boards are increasingly favored in modern construction.

For builders, contractors, and designers seeking a durable, safe, and eco-friendly solution, MgO panels provide clear advantages over traditional cement boards.

If you want expert guidance or samples for your next project, contact our team today to explore how MgO panels can elevate your construction standards.

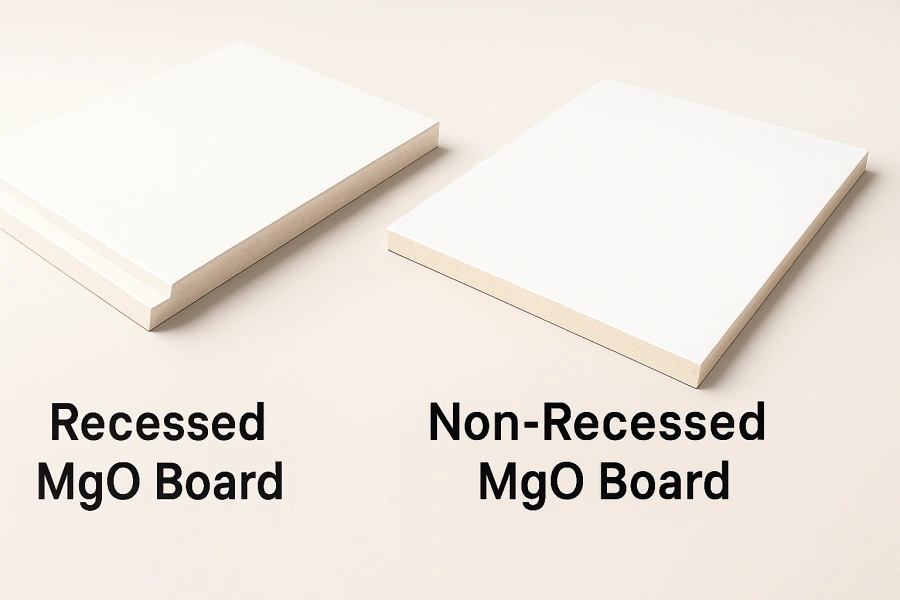

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Compare MgSO4 board vs MgCl2 board: discover key differences, performance, and durability to choose the best mgo board for your project.

Discover the fire rating and fire resistance of MGO board. Learn how this fire-rated magnesium oxide board protects buildings and ensures occupant safety.