Table of Contents

Ask Us Any Question

Introduction

In the fast-paced US construction industry, builders and homeowners are increasingly looking for building materials that are safe, durable, and environmentally responsible. One material gaining wide recognition is MGO board USA (magnesium oxide board), known for its fire-resistant, moisture-proof, and eco-friendly properties. These characteristics make it a reliable choice for modern residential, commercial, and renovation projects across the United States.

Over the past decade, demand in the US has grown for building materials that meet strict safety standards while offering long-term performance. Traditional options, such as drywall or plywood, often fall short in areas like fire resistance or moisture durability. In contrast, magnesium oxide boards produced for the US market provide a stronger, safer alternative.

Adoption of MGO panels in the USA also aligns with the increasing emphasis on sustainable construction. Architects and builders are prioritizing materials that contribute to healthier indoor environments, and MGO boards meet these expectations with their non-toxic composition and low environmental impact during production.

This article explores why MGO board USA is a smart choice for construction in the United States, examining its composition, properties, benefits, and tips for selecting reliable suppliers. Whether you are building a new home, a commercial space, or renovating an existing structure, understanding the advantages of these boards can help you make informed decisions that enhance safety, durability, and overall project value.

What Is MGO Board?

MGO board is a type of building material primarily made from magnesium oxide, often combined with compounds like magnesium chloride or magnesium sulfate. These boards are inorganic, durable, and safe for indoor use, offering a superior alternative to traditional gypsum drywall or fiberboard.

Composition and Structure

The key ingredient in magnesium oxide boards for the US market is magnesium oxide, which provides excellent fire resistance and structural integrity. Depending on the intended use, magnesium chloride or magnesium sulfate may also be included as binders, contributing to water resistance and overall durability.

Proper production processes, such as pre-soaking boards that contain magnesium chloride, prevent potential issues like efflorescence or corrosion, ensuring stable, long-lasting performance in American homes and commercial buildings.

Many boards also include reinforcing fibers, such as glass fiber mesh, which improve impact resistance and prevent cracking. This combination of inorganic materials and fiber reinforcement makes mgo board USA a reliable option for walls, ceilings, floors, and other structural applications.

Key Properties

MGO board USA offers several advantages that make it ideal for construction projects in the United States:

-

Fire Resistance – Withstand high temperatures, providing crucial safety in residential and commercial buildings.

-

Moisture and Mold Resistance – Less prone to water damage or mold growth compared with conventional drywall.

-

Durability and Strength – Strong and long-lasting, capable of enduring everyday wear and tear.

-

Eco-Friendly and Non-Toxic – Free from harmful chemicals, contributing to healthier indoor air quality.

-

Versatility – Suitable for walls, ceilings, flooring, sub-flooring, and even exterior cladding with proper treatment.

In short, MGO board combines fire safety, durability, and environmental friendliness, making it an increasingly popular choice for builders, architects, and homeowners across the United States.

Why MGO Board USA Stands Out

Builders and homeowners in the United States are increasingly choosing mgo board because it offers a combination of safety, reliability, and environmental benefits that are difficult to match with traditional building materials. Here are the key reasons why these boards stand out in the American construction market.

Compliance with US Building Codes

One of the primary considerations in US construction is compliance with strict local and national building codes. Magnesium oxide boards produced for the US market are manufactured to meet these standards, including fire resistance, structural integrity, and moisture control. This ensures that builders can use the boards in both residential and commercial projects without concerns about legal or safety compliance.

Meeting US building codes also makes it easier for architects and contractors to specify MGO boards in construction plans. The consistent quality and standardized production processes of US MGO boards give professionals confidence that the material will perform as expected under American regulatory requirements.

Superior Fire Resistance for American Homes

Fire safety is a critical issue in many parts of the United States, especially in regions prone to wildfires. Unlike traditional drywall, mgo boards are inherently fire-resistant due to their inorganic composition. They do not ignite, release toxic fumes, or deform easily when exposed to high temperatures.

This fire-resistant property makes MGO boards ideal for use in walls, ceilings, and floors in both residential and commercial buildings. For homeowners, it means enhanced protection for families and properties. For commercial buildings, it provides additional safety compliance, potentially reducing insurance costs and liability risks.

Eco-Friendly and Sustainable Production

Sustainability is another key factor that distinguishes MGO panels in the USA. These boards are made from non-toxic, naturally sourced materials, avoiding harmful additives like formaldehyde or asbestos. Many US manufacturers also implement environmentally responsible production techniques, reducing energy use and minimizing waste.

For builders and homeowners seeking green construction solutions, US MGO boards offer an attractive alternative that aligns with LEED certification requirements and other sustainable building initiatives. Using these boards contributes to healthier indoor air quality and a reduced environmental footprint.

Compatibility with US Construction Materials

Another advantage of US MGO boards is their compatibility with common American construction materials. Whether installing drywall, plywood, or sub-floor systems, magnesium oxide boards for US projects integrate seamlessly with existing materials.

They can be easily cut, drilled, and fastened using standard tools, and they accept paints, adhesives, and finishes commonly used in US construction. This versatility reduces labor time, simplifies installation, and ensures that projects remain on schedule.

Benefits of Using MGO Board in US Construction

Using US MGO board in construction projects provides multiple advantages that make it an attractive choice for builders, architects, and homeowners. From enhanced safety to cost savings, the benefits are clear and measurable.

Safety and Fire Protection

Safety is a top priority in US construction, and magnesium oxide boards in the USA excel in this area. Their inorganic composition makes them highly fire-resistant, helping to prevent the spread of flames and protecting both occupants and property. Unlike traditional gypsum drywall, which can combust and release harmful smoke, MGO boards remain stable under high temperatures.

In addition to fire resistance, these boards are mold- and moisture-resistant. This reduces the risk of structural weakening and indoor air quality issues, providing safer living and working environments. For areas prone to extreme weather, such as humid coastal regions or wildfire-prone states, these properties are especially valuable.

Durability and Long-Term Cost Savings

One of the strongest selling points of US MGO board is its durability. These boards resist cracking, warping, and degradation over time, even in challenging environmental conditions. Compared to traditional drywall or plywood, magnesium oxide boards offer a longer service life, which can translate into significant cost savings for homeowners and property managers.

By investing in durable materials upfront, builders and homeowners can reduce maintenance costs, avoid frequent replacements, and enhance the overall value of their properties. This long-term performance makes MGO boards a smart choice for both new construction and renovation projects in the United States.

Easy Installation and Versatility

Another advantage of magnesium oxide panels for US projects is their ease of installation. The boards can be cut, drilled, and fastened using standard tools, which simplifies construction and reduces labor costs. Their compatibility with common US construction materials, such as subfloor systems, drywall frameworks, and exterior sheathing, ensures a smooth integration into various building projects.

Furthermore, MGO boards are versatile in application. They can be used for walls, ceilings, floors, partitions, and even exterior cladding when properly treated. This flexibility allows builders to standardize materials across a project, streamlining procurement and installation processes.

Low Maintenance Requirements

Once installed, MGO board requires minimal maintenance. Its resistance to moisture, mold, and pests ensures that buildings remain in excellent condition for years without intensive upkeep. The boards also accept paints, coatings, and finishes commonly used in the US, allowing for aesthetic customization without compromising performance.

Low maintenance requirements save both time and money over the life of a building. For homeowners, this translates to peace of mind, while for commercial projects, it reduces ongoing operational costs and preserves property value.

How to Choose a Reliable MGO Board USA Supplier

Selecting the right supplier is crucial when sourcing MGO board for construction projects. A reliable supplier ensures consistent product quality, compliance with US building standards, and timely delivery, all of which are essential for smooth project execution. Here are key factors to consider when choosing a supplier.

Quality Certifications and US Compliance

A trustworthy supplier should provide evidence that their magnesium oxide boards for the US market meet relevant safety and quality standards. This includes compliance with US building codes, ASTM testing, and fire-resistance ratings.

Certifications from recognized organizations not only confirm that the boards are safe and reliable but also give builders and architects confidence that their projects will pass inspections. For instance, boards with fire-resistance certification are often required in commercial buildings and multi-family residences in the United States.

Track Record and Experience in the US Market

Experience matters. Suppliers who have successfully served the US market for several years are more likely to understand the unique requirements of American construction, including climate considerations, regulatory compliance, and customer expectations.

When evaluating potential suppliers, consider their portfolio of completed projects in the United States. References or case studies from previous US clients can provide valuable insight into the supplier’s reliability, product performance, and customer service.

Product Range and Customization Options

A reliable US MGO board supplier should offer a diverse product range to meet different project needs. This includes various board thicknesses, sizes, and finishes suitable for walls, ceilings, flooring, and exterior applications.

Customization options are also important. Depending on the project, builders may require specific board dimensions, pre-cut panels, or enhanced properties such as additional water resistance. Suppliers who can accommodate these requirements demonstrate flexibility and a customer-focused approach.

Delivery and After-Sales Support

Timely delivery is critical in construction projects to avoid delays and cost overruns. Reputable suppliers maintain robust logistics capabilities and transparent communication regarding shipping schedules.

After-sales support is equally important. Suppliers who provide installation guidance, technical support, and warranty services ensure that any potential issues are resolved quickly, giving builders and property owners peace of mind.

By carefully evaluating these factors, construction professionals can select a US MGO board supplier that not only delivers high-quality materials but also supports successful project execution from start to finish.

Conclusion

For builders, architects, and homeowners in the United States, choosing the right building materials is critical for safety, durability, and long-term value. MGO board USA—magnesium oxide board produced or supplied for the US market—offers a combination of fire resistance, moisture protection, strength, and environmental friendliness that makes it an ideal choice for a wide range of construction projects.

These boards stand out for their compliance with US building codes, superior fire performance, and compatibility with common American construction materials. Their durability and low maintenance requirements reduce long-term costs, while versatile applications make them suitable for walls, ceilings, floors, and even exterior projects.

Selecting a reliable supplier further ensures consistent quality, timely delivery, and professional support, which are essential for smooth project execution. Builders can feel confident knowing that they are using materials that not only meet regulatory standards but also contribute to safer, more sustainable buildings.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

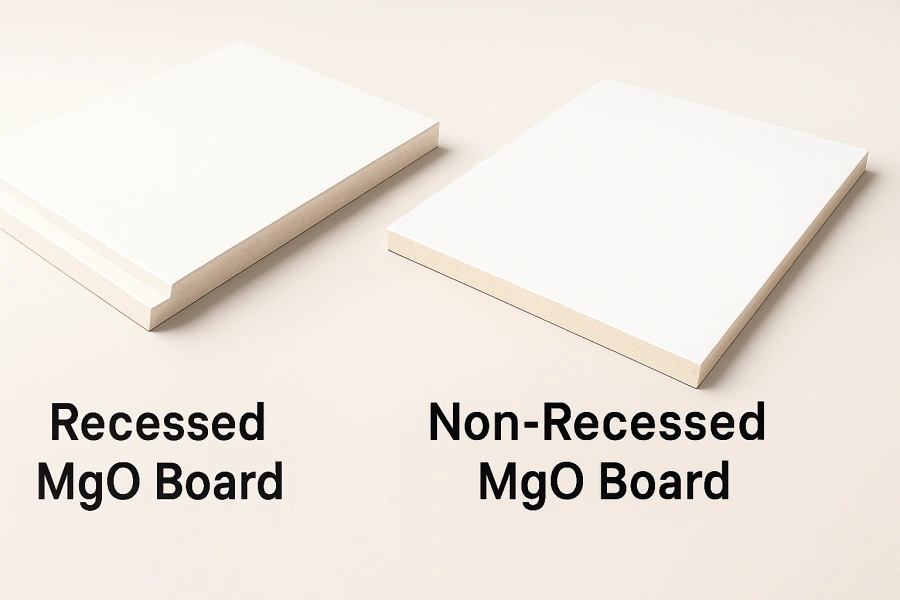

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

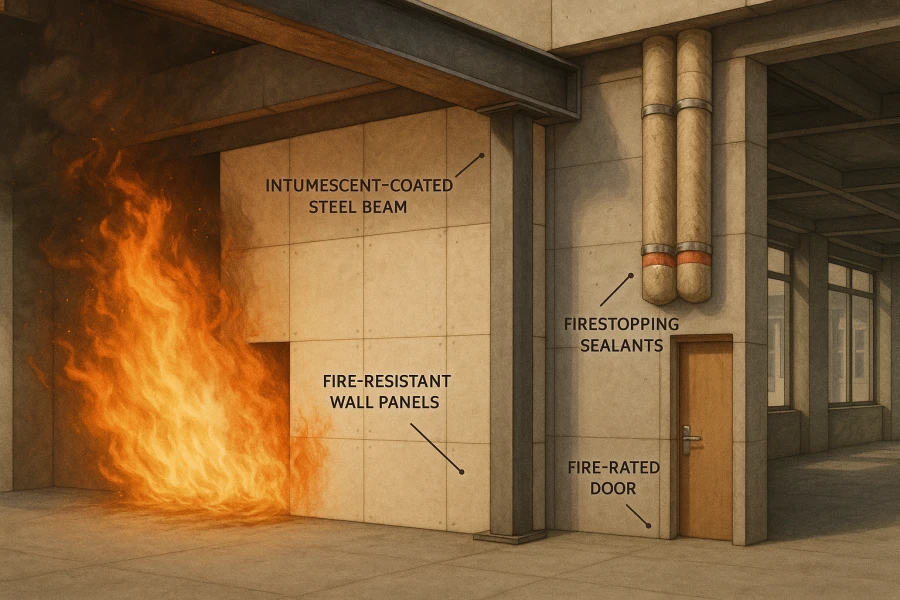

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.