Table of Contents

Ask Us Any Question

Introduction — Why MGO Board Price Matters in 2026

In the global construction market, magnesium oxide boards (MGO boards) have become one of the most reliable fireproof and moisture-resistant building materials. From wall partitions to subflooring and exterior façades, MGO boards are now replacing traditional drywall and fiber cement boards in many projects.

For builders, distributors, and project planners, understanding the current MGO board price is crucial in 2026. The cost of construction materials continues to fluctuate due to changes in raw material costs, logistics, and international demand. Knowing the average price per square meter not only helps estimate project budgets but also ensures you’re getting a fair and competitive deal from suppliers.

As we move through 2026, this guide provides a detailed overview of MGO board prices, key influencing factors, and practical tips to help you secure the best value for your investment.

Average MGO Board Price per m² in 2026

The average MGO board price in 2026 varies depending on thickness, density, and surface finish. Generally, prices are calculated per square meter (m²), which makes it easier for project planners and contractors to estimate material costs.

Typical MgO Board Price Range by Thickness

-

6mm MGO board: Approx. $8–$12 per m²

-

8mm MGO board: Approx. $10–$15 per m²

-

12mm MGO board: Approx. $14–$20 per m²

Note: Prices can fluctuate depending on market demand, raw material costs, and supplier location.

Price Units and Measurement

-

MGO boards are usually sold per sheet or per m², and the exact pricing depends on sheet size.

-

Common sheet dimensions: 1220×2440mm, 1200×2600mm, 1200×3000mm.

-

Calculating price per m² allows easy comparison between different thicknesses and sizes.

Understanding these average costs helps you plan your budget accurately and compare offers from different suppliers without confusion.

Factors That Affect MGO Board Price

The MGO board price is influenced by multiple factors that determine both production cost and final market price. Understanding these factors helps buyers make informed purchasing decisions.

1. Raw Material Costs

The main components of MGO boards include magnesium oxide, magnesium chloride or sulfate, fibers, and fillers. Fluctuations in raw material prices directly affect the cost per square meter. High-purity magnesium oxide or imported additives typically increase the price, while locally sourced materials may reduce it.

2. Board Specifications

-

Thickness and density: Thicker boards and higher density panels provide better fire resistance and durability but cost more.

-

Strength and flexural properties: Boards designed for heavy-duty or exterior applications may carry a premium.

3. Surface Finish and Lamination

-

Boards with PVC lamination, UV coating, or smooth finishes are more expensive due to additional processing.

-

Dust-free boards for full-surface lamination or decorative applications may also increase cost.

4. Packaging and Logistics

-

Export packaging (pallets, dunnage, air bags) and shipping terms (FOB, CIF) impact the delivered price.

-

Bulk shipments usually reduce unit cost per m² compared to small orders.

5. Order Quantity and Customization

-

Larger orders allow suppliers to offer better pricing due to economies of scale.

-

Custom sizes, tongue-and-groove designs, or OEM branding may increase the unit price.

By understanding these factors, buyers can balance cost and quality, ensuring they get the right MGO boards for their projects without overpaying.

Price Comparison — MGO Board vs Fiber Cement Board

When planning a construction project, comparing MGO boards with traditional fiber cement boards can help you evaluate both cost and value.

| Feature | MGO Board | Fiber Cement Board |

|---|---|---|

| Price per m² (6–12mm) | $8–$20 | $6–$15 |

| Fire Rating | A2-s1,d0 | A2-s1,d0 (varies with manufacturer) |

| Moisture Resistance | High | High |

| Ease of Cutting & Milling | Easy | Harder, requires more effort |

| Weight | Lighter | Heavier |

| Installation Efficiency | Faster due to machinability | Slower due to brittleness |

Key Takeaways:

-

Although fiber cement boards can be slightly cheaper per m², MGO boards offer better fire safety, easier machining, and faster installation.

-

For projects requiring full-surface lamination, tongue-and-groove systems, or lightweight panels, MGO boards may provide better overall value despite a slightly higher unit cost.

By considering these factors, buyers can make a more informed choice between cost savings and long-term performance.

How to Get the Best MgO Board Price

Securing a competitive MGO board price requires careful planning and strategic choices. Here are some practical tips:

1. Optimize Thickness and Size

Choosing the right board thickness (6mm, 8mm, 12mm) and sheet dimensions that match your project needs can reduce waste and cost per m². Standard sizes like 1220×2440mm often offer the best price.

2. Order in Bulk

Large orders benefit from economies of scale, lowering the cost per square meter. Suppliers like Suparna often provide better pricing for orders of 5,000+ sheets per year.

3. Choose Suitable Surface Finish

Boards without excessive lamination or coatings are generally cheaper. If your project requires dust-free lamination or decorative finishes, consider balancing aesthetics with budget.

4. Consider Shipping Terms

-

FOB may be more cost-effective for experienced importers.

-

CIF includes shipping and insurance but may increase the per-m² cost.

5. Work with a Reliable Supplier

Partnering with a trusted manufacturer like Suparna ensures consistent quality, stable pricing, and timely delivery. Our expertise in producing high-density, easy-to-machine, fireproof MGO boards helps clients optimize both cost and performance.

By following these strategies, buyers can secure the best price without compromising quality, ensuring their project stays within budget while achieving superior fire and moisture resistance.

Conclusion

In 2026, understanding the current MGO board price per m² is essential for architects, builders, and distributors planning their projects. Prices vary depending on thickness, density, surface finish, packaging, and order quantity, but knowing the average ranges helps you budget accurately and make informed purchasing decisions.

For projects requiring high-quality, fireproof, moisture-resistant, and easy-to-machine MGO boards, working with a reliable supplier like Suparna ensures consistent quality and competitive pricing.

💡 Take Action:

Send us your project specifications today to receive a personalized MGO board quote. Our team will provide detailed pricing, available sheet sizes, and delivery options to help you plan your next project efficiently and cost-effectively.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

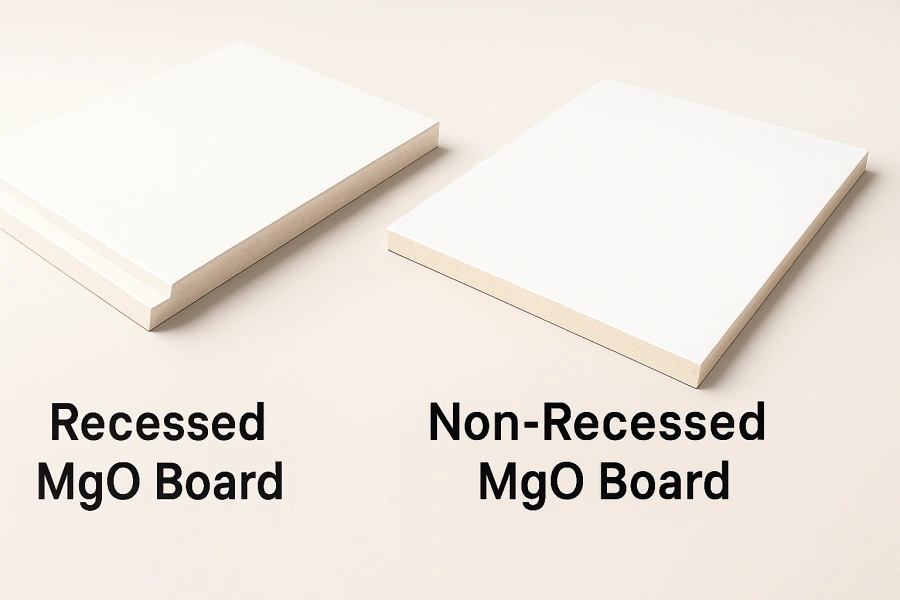

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

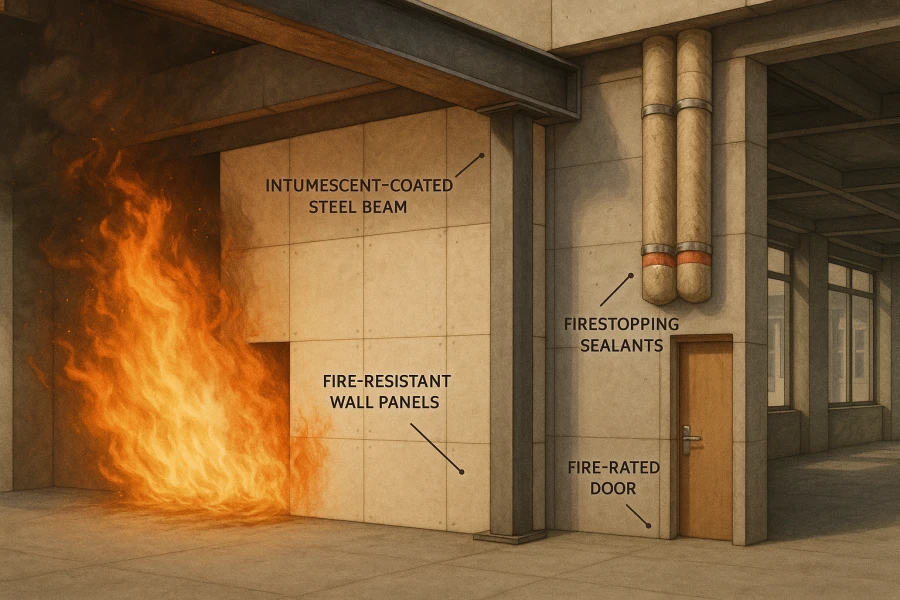

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.