Table of Contents

Ask Us Any Question

1. Introduction

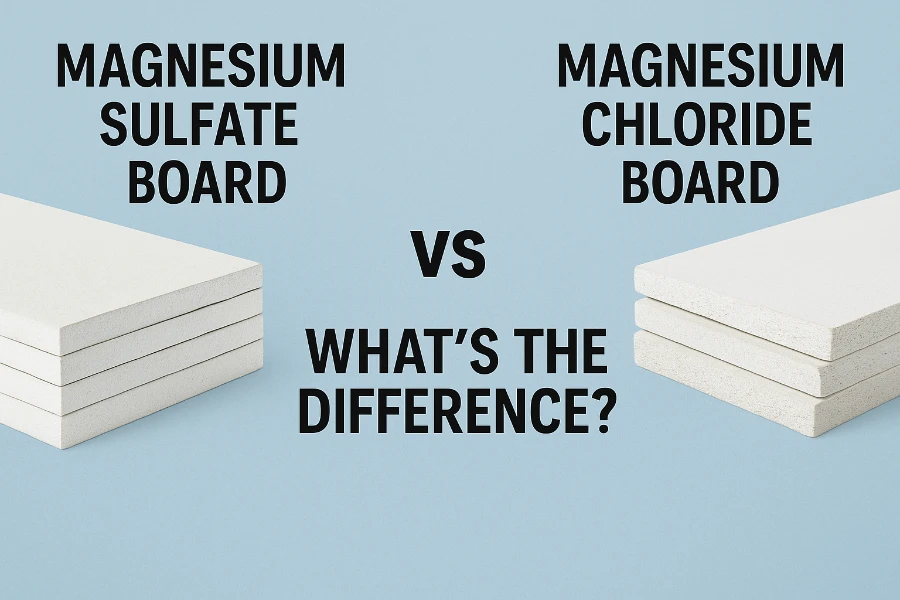

When it comes to selecting the right type of magnesium oxide board (MgO board), one critical distinction that professionals often overlook is the difference between magnesium sulfate board and magnesium chloride board. Although both are considered types of MgO boards, their chemical composition and resulting performance characteristics vary significantly. These differences can have a major impact on the durability, stability, and safety of your construction projects.

In this article, we’ll explore the differences between the two, focusing on their raw materials, moisture resistance, corrosion behavior, long-term stability, environmental impact, and suitable applications. Whether you’re a builder, architect, or procurement officer, understanding these distinctions can help you make a smarter choice.

2. What Is Magnesium Sulfate Board (MgSO₄ Board)?

Magnesium sulfate board, also referred to as magnesium sulphate board or MgSO₄ board, is a high-performance, non-toxic, fire-resistant construction panel primarily composed of magnesium oxide (MgO), magnesium sulfate (MgSO₄), and other mineral fillers. Unlike its chloride-based counterpart, it contains no chloride ions, making it inherently more stable and less reactive.

Key Characteristics:

-

Non-corrosive: No risk of chloride-induced corrosion on metal fasteners or embedded steel.

-

Moisture-resistant: Performs well in humid conditions without warping or swelling.

-

Fire-resistant: Achieves Class A fire rating under most global standards.

-

Environmentally friendly: Free of halogens, asbestos, and formaldehyde.

-

Low alkalinity: Minimizes reactivity with other building materials.

-

Versatile: Suitable for both internal and semi-external applications.

Common Applications:

-

Sub-flooring

-

Wall linings

-

Partition panels

-

Ceilings

-

Fire-rated assemblies

Its chemical stability and long-term durability make it a preferred choice in premium projects, especially where moisture or metal framing is involved.

3. What Is Magnesium Chloride Board?

Magnesium chloride board is another type of MgO board, typically composed of magnesium oxide and magnesium chloride (MgCl₂). It has long been used for its excellent fire-resistance, cost-effectiveness, and ease of manufacturing.

However, the presence of chloride ions introduces certain vulnerabilities, especially in high-humidity or corrosive environments.

Advantages:

-

Affordable: Lower production cost compared to MgSO₄ board.

-

Fire-rated: Still meets Class A fire resistance standards.

-

Better compatibility: Magnesium chloride boards tend to offer better compatibility with surface treatments, such as lamination with PVC films or decorative papers. This makes them a popular choice in applications where post-processing or aesthetic finishing is required. In contrast, magnesium sulfate boards can sometimes show weaker adhesion with certain surface coatings.

Disadvantages:

-

Chloride ion issues: Can cause steel corrosion and surface moisture accumulation.

-

Moisture sensitivity: Prone to absorbing moisture, which can compromise long-term stability.

4. Key Differences Between the Two Boards

| Property | Magnesium Sulfate Board (MgSO₄) | Magnesium Chloride Board (MgCl₂) |

|---|---|---|

| Main Salt Component | Magnesium sulfate (non-chloride) | Magnesium chloride (chloride-based) |

| Corrosion Risk | None | High (without treatment) |

| Moisture Resistance | Excellent | Moderate to poor |

| Stability Over Time | High | Medium |

| Fire Resistance | Class A | Class A |

| Environmental Profile | Halogen-free, low VOC | Contains chloride |

| Metal Compatibility | Safe with steel framing | Can lead to rust and deterioration |

| Cost | Moderate to high | Low |

As shown above, magnesium sulfate boards offer superior performance in nearly every category, especially in challenging environments.

5. Which One Should You Choose?

Choose Magnesium Sulfate Board if:

-

Your project is in a humid or coastal environment.

-

Long-term durability and low maintenance are required.

-

You’re using metal framing or fasteners.

-

Environmental certifications and halogen-free materials are important.

-

You seek higher-end product performance with fewer long-term risks.

Choose Magnesium Chloride Board if:

-

Cost is a major constraint.

-

It’s intended for dry interior use with minimal moisture exposure.

-

You are using treated or non-metallic framing components.

- You need to laminate the board with PVC films or decorative finishes.

It’s also worth noting that not all magnesium chloride boards are created equal. Advanced manufacturers are now using techniques to mitigate some of its downsides, which brings us to the next section.

6. Environmental & Safety Considerations

In recent years, construction professionals have grown increasingly concerned about the chloride-induced corrosion associated with magnesium chloride boards. This issue arises when excess chloride ions migrate through the board, attracting moisture and leading to:

-

Corrosion of embedded steel or fasteners

-

Crying or sweating mgo board (surface moisture accumulation)

-

Structural instability over time

To address this, Suparna, a leading MgO board manufacturer in China, has implemented a soaking technique during the production of its magnesium chloride boards. This process helps extract free chloride ions from the material before curing. As a result, their chloride-based boards exhibit greatly reduced corrosive potential and minimized risk of moisture accumulation, making them more suitable for wider use.

However, magnesium sulfate boards inherently avoid this problem, making them the first choice for green buildings, hospitals, schools, and other applications where low VOC, non-corrosiveness, and long service life are essential.

7. Conclusion

Both magnesium sulfate and magnesium chloride boards serve useful roles in the construction industry, but their differences are more than chemical—they affect your project’s performance, durability, and long-term safety.

To summarize:

-

Magnesium sulfate boards are ideal for demanding applications where moisture, corrosion resistance, and environmental safety matter most.

-

Magnesium chloride boards may be acceptable in controlled environments, temporary projects, cost-sensitive applications, or products that require surface lamination—especially when enhanced with proper manufacturing techniques, like the soaking process used by Suparna.

Ultimately, understanding these differences enables you to make informed material choices that align with your project’s technical, budgetary, and environmental requirements.

8. FAQ

Q1: What is the difference between magnesium sulfate board and magnesium chloride board?

A: The key difference lies in their salt content. Magnesium sulfate boards contain non-corrosive sulfate salts, while chloride boards contain chloride ions that may lead to steel corrosion if not properly treated.

Q2: Is magnesium sulfate board waterproof?

A: While not fully waterproof, magnesium sulfate boards are highly moisture-resistant and do not swell or degrade when exposed to humidity.

Q3: Can magnesium chloride board cause metal corrosion?

A: Yes, unless treated during manufacturing, chloride ions can cause corrosion of steel framing or fasteners. However, some manufacturers like Suparna use soaking techniques to reduce this risk.

Q4: Which MgO board is better for flooring or humid environments?

A: Magnesium sulfate board is generally the better option for subflooring or moisture-prone areas due to its stability and non-corrosiveness.

Still not sure which board fits your project best? Contact us to get expert advice or request a free sample

Explore the best heat proof and heat resistant materials for safer construction. Learn their benefits, applications, and safety advantages.

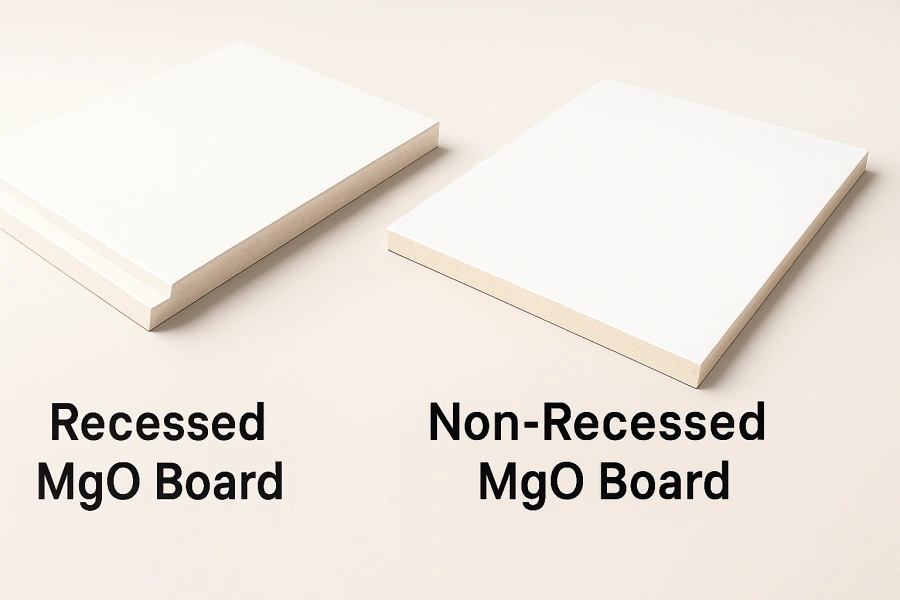

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Compare MgSO4 board vs MgCl2 board: discover key differences, performance, and durability to choose the best mgo board for your project.