Table of Contents

Ask Us Any Question

1. Introduction

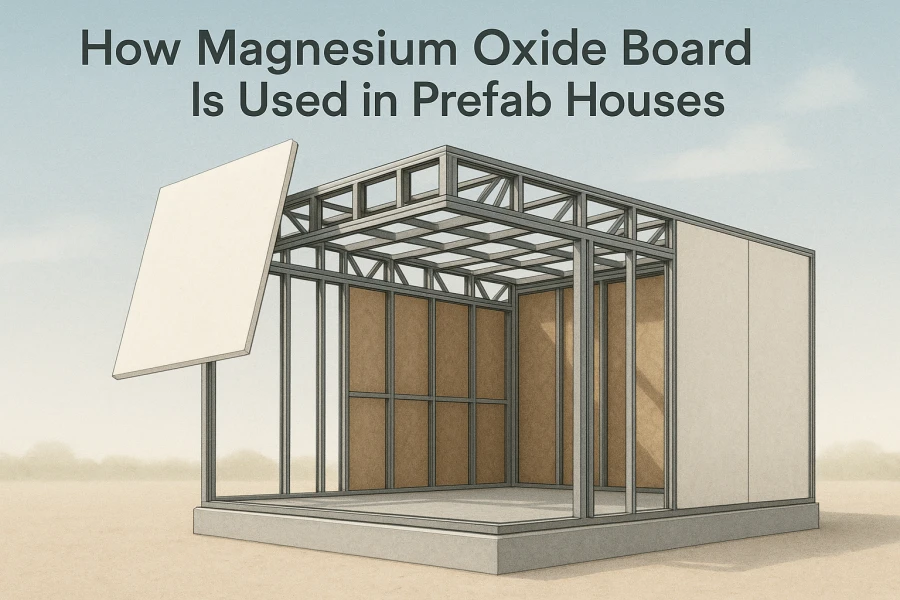

Prefab houses, also known as modular or prefabricated homes, have been gaining significant attention worldwide due to their efficiency, sustainability, and consistent quality. Unlike traditional on-site construction, prefab houses are partially or fully manufactured in a controlled factory environment before being transported and assembled at the construction site. This approach reduces construction time, minimizes waste, and ensures higher precision in building components.

One of the key factors determining the success and durability of prefab homes is the choice of building materials. Magnesium oxide board (MgO board) has emerged as a highly reliable and versatile material for modern modular construction. Known for its fire resistance, moisture resistance, structural strength, and eco-friendly properties, MgO board is increasingly used in various components of prefab houses, from walls and floors to ceilings and wet areas.

In this article, we will explore how MgO board is applied in prefab houses, highlighting its technical properties, advantages for modular construction, installation methods, and real-world applications. By understanding the role of MgO board, manufacturers and builders can make informed decisions to enhance the safety, durability, and sustainability of prefabricated housing projects.

2. Properties and Advantages of MgO Board for Prefab Construction

Magnesium oxide board (MgO board) is increasingly recognized as one of the most suitable materials for prefab houses due to its combination of superior physical properties and practical advantages. Its performance characteristics not only meet the rigorous demands of modular construction but also enhance the safety, durability, and efficiency of prefabricated housing projects.

2.1 Fire Resistance

MgO board is non-combustible and offers a high fire-resistance rating, making it an essential material for modular homes where safety is a top priority. Unlike traditional gypsum or wood-based panels, MgO board does not emit toxic smoke or fumes when exposed to fire.

Benefits for prefab houses include:

-

Reliable fire protection for walls, ceilings, and floor underlayments

-

Compliance with international fire safety standards (EN, ISO, ASTM equivalents)

-

Suitable for multi-story modular buildings requiring strict fire codes

These characteristics make MgO board an ideal choice for both residential and commercial prefab modules, ensuring long-term safety and compliance with regulations.

2.2 Moisture and Mold Resistance

Prefab modules often experience long transportation distances and varying environmental conditions. MgO board has low water absorption and excellent resistance to warping, swelling, and mold growth.

Practical advantages include:

-

Stability of panels during shipping and storage

-

Reduced risk of damage in wet or humid climates

-

Suitable for wet areas such as bathrooms, kitchens, or laundry rooms

By maintaining dimensional integrity, MgO board helps modular components arrive on-site in optimal condition, reducing installation issues and maintenance costs.

2.3 High Strength and Structural Stability

MgO board exhibits high compressive and flexural strength, making it capable of supporting screws, fasteners, and other attachments securely.

Applications in prefab construction:

-

Structural and non-structural walls

-

Floor and roof underlayments

-

Structural Insulated Panels (SIPs) requiring rigidity

Its strength ensures that modular units remain stable and durable, even under mechanical stress or during handling and installation.

2.4 Ease of Fabrication and Installation

MgO board is easy to cut, trim, and drill, making it highly compatible with automated factory processes. Panels can be prepared with CNC cutting or pre-drilled holes, streamlining assembly.

Advantages for prefab houses:

-

Faster factory assembly and reduced labor costs

-

Minimal on-site adjustments due to precise pre-fabrication

-

Compatibility with screws, adhesives, and mechanical fasteners

These properties allow manufacturers to produce consistent, high-quality modules efficiently.

2.5 Environmental and Sustainable Benefits

MgO board is environmentally friendly, containing no VOCs, asbestos, or harmful organic chemicals. It is recyclable and contributes to green building standards.

Key benefits include:

-

Supports LEED, BREEAM, or local green certifications

-

Improves energy efficiency and indoor air quality

-

Aligns with sustainable construction practices in modular housing

By choosing MgO board, prefab builders can achieve higher environmental performance while meeting modern regulatory requirements.

2.6 Production and Handling Advantages

MgO board’s physical stability and durability offer additional benefits for production and logistics:

-

Reduced waste and defects during factory assembly

-

Resistance to vibration and impact during shipping

-

Reliable protection of panels during long-distance transportation

These advantages help modular manufacturers save time, reduce costs, and deliver high-quality prefab units consistently.

3. Applications of MgO Board in Prefab Houses

Magnesium oxide board (MgO board) is highly versatile and can be used in nearly every component of a prefab house. Its properties—fire resistance, moisture stability, high strength, and ease of fabrication—make it suitable for walls, floors, ceilings, wet areas, and structural panels. Below are the most common applications.

3.1 Interior Wall Panels

MgO board is commonly used for interior walls in modular homes, including:

-

Partition walls in bedrooms, living rooms, and offices

-

Fire-rated walls separating different modules

-

Decorative walls that can be painted, laminated, or tiled

Thickness and Finishes

-

Typical thicknesses: 8–12 mm for lightweight panels; thicker boards (15–20 mm) for added rigidity

-

Can be finished with paint, wallpaper, tiles, or laminates without additional support

Benefits:

-

High fire and mold resistance for indoor safety

-

Easy to cut and install in factory settings

-

Minimal maintenance during the building’s lifecycle

3.2 Exterior Wall Sheathing

MgO board can be used as an exterior wall base layer:

-

Acts as a substrate for decorative cladding or EIFS (Exterior Insulation and Finish Systems)

-

Provides fire protection for multi-story prefab modules

-

Offers dimensional stability under temperature changes and humidity

Multi-Story Applications

-

Installed over light steel or timber frames

-

Suitable for high-rise modular apartments and office buildings

-

Improves long-term durability of facades

3.3 Floor Underlayment

Floors in prefabricated homes require a stable, flat base to prevent deformation and support finishes. MgO board is ideal for:

-

Tile, laminate, or SPC flooring installation

-

Raised flooring systems with light steel or timber frames

-

Fireproof and moisture-resistant underlayments

Thickness and Load-Bearing

-

Typical thicknesses: 18–22 mm depending on floor structure

-

Provides excellent compressive strength for residential and commercial modules

3.4 Roof and Ceiling Panels

MgO board can be used in roof and ceiling modules for prefab houses:

-

Roof decking substrate

-

Ceiling panels with fire protection

-

Humidity-resistant and dimensionally stable under environmental stress

Advantages

-

Lightweight yet strong

-

Resistant to sagging and warping

-

Enhances fire safety for entire prefab modules

3.5 Structural Insulated Panels (SIPs)

MgO board is increasingly used in SIPs for modular construction:

-

Forms the outer layers of sandwich panels

-

Core insulation can include EPS, XPS, PIR, PU foam, or rock wool

Benefits of MgO SIPs

-

Combines structural strength, thermal insulation, and fire resistance

-

Lightweight for easy transport

-

Faster factory assembly compared to OSB-based SIPs

-

Excellent acoustic and thermal performance

3.6 Modular Bathroom Pods / Wet Areas

Prefabricated bathroom modules require moisture- and mold-resistant materials. MgO board is ideal for:

-

Shower walls and ceilings

-

Under-tile backer boards in wet areas

-

Chemical-resistant surfaces for cleaning

Advantages Over Gypsum Boards

-

High water resistance

-

Mold and mildew prevention

-

Suitable for daily steam exposure and cleaning

3.7 Exterior Facade and Fire Barriers

MgO board is also used in exterior cladding systems and as fire-rated barriers:

-

Acts as a base layer for decorative facades

-

Serves as a fire-resistant barrier between modular units

-

Provides long-term durability against weathering and UV exposure

Benefits

-

Meets both aesthetic and safety requirements

-

Supports multi-story modular construction

-

Improves overall lifespan of prefabricated buildings

4. Installation Methods

MgO board is designed for both factory and on-site installation, making it ideal for prefabricated and modular housing. Proper installation ensures safety, dimensional stability, and long-term performance.

4.1 Factory Assembly

In prefab construction, the majority of MgO panels are prepared and partially assembled in the factory. This controlled environment allows for precision and speed in module production.

Panel Preparation

-

Cutting boards to exact dimensions using CNC or manual methods

-

Pre-drilling holes for screws or mechanical fasteners

-

Adding optional surface finishes such as primers, paints, or laminates

Panel Attachment

-

Panels are fastened to light steel or timber frames

-

Adhesives or screws ensure strong and secure connections

-

Fire- and moisture-resistant sealants can be applied at joints for enhanced protection

Advantages of Factory Assembly

-

Consistent quality and precise dimensions

-

Reduced labor and errors on site

-

Faster overall production cycle for prefab modules

4.2 On-Site Assembly

Once the prefabricated modules are transported to the construction site, MgO panels are integrated into the final structure.

Module Connection

-

Modules are lifted into place using cranes or other handling equipment

-

MgO panels are screwed, glued, or mechanically fastened to adjacent components

-

Fire- and moisture-resistant compounds seal joints between panels

Finishing and Adjustments

-

Panels are ready for painting, tiling, or laminate finishes

-

Minimal adjustments are required due to dimensional stability

-

Ensures faster installation compared to traditional materials

Benefits of On-Site Use

-

Reduced construction time and labor costs

-

Reliable performance under various environmental conditions

-

Preserves panel integrity and module quality during final assembly

4.3 Tips for Optimizing Installation

-

Use standardized panel sizes to streamline factory and site processes

-

Pre-plan fastener positions to minimize on-site drilling

-

Store MgO panels in dry, ventilated areas to prevent accidental moisture exposure before installation

-

Incorporate fire- and moisture-rated sealants for joints, especially in wet or high-risk areas

5. Case Studies / Real-World Examples

To better understand the versatility and benefits of MgO board in prefab houses, it is helpful to examine real-world applications across different regions. These examples demonstrate how MgO board enhances safety, efficiency, and durability in modular construction projects.

5.1 Europe: SIP Walls and Wet Area Modules

In several European countries, modular housing manufacturers use MgO board in Structural Insulated Panels (SIPs) and wet-area modules such as bathrooms:

-

Application: MgO boards are used as outer layers of SIPs, combined with EPS or XPS insulation cores. Wet-area walls and ceilings are also lined with MgO boards.

-

Benefits:

-

High fire resistance ensures compliance with EU building regulations

-

Moisture and mold resistance protect wet areas during transport and usage

-

Panels provide excellent thermal and acoustic insulation

-

-

Outcome: Faster factory assembly, reliable module integrity during shipping, and enhanced occupant safety

5.2 Australia: Floor Underlayment and Tile Installations

Prefab homes in Australia often face high humidity and occasional flooding risks. MgO boards are used for floor underlayments under tiles or laminate:

-

Application: 12–20 mm thick MgO boards installed over timber or light steel framing before finishing floors

-

Benefits:

-

Moisture-resistant base prevents warping or swelling

-

High compressive strength supports heavy flooring and furniture

-

Reduces installation time compared to cement or traditional plywood underlayments

-

-

Outcome: Long-lasting, stable floors with minimal maintenance, suitable for residential modular homes

5.3 Middle East: Exterior Cladding and Interior Partitions

In the Middle East, where heat, humidity, and fire safety are major concerns, MgO boards are widely used in exterior and interior applications:

-

Application:

-

Exterior wall sheathing and base layers for decorative cladding

-

Interior partitions in modular office buildings and residential units

-

-

Benefits:

-

Fire-resistant panels enhance safety for multi-story modular buildings

-

UV and heat-resistant materials increase façade longevity

-

Lightweight boards reduce transportation and installation costs

-

-

Outcome: Durable exterior and interior modular solutions that meet local building codes

5.4 Lessons Learned

From these case studies, the following lessons are clear:

-

MgO board performs exceptionally well under diverse environmental conditions

-

Factory-prepared modules with MgO panels reduce on-site labor and construction errors

-

Multi-purpose applications (walls, floors, ceilings, SIPs, wet areas) make MgO board highly versatile

-

Manufacturers benefit from increased efficiency, reduced waste, and compliance with fire and environmental regulations

6. Conclusion

Magnesium oxide board (MgO board) has proven to be an exceptional material for prefab houses and modular construction. Its combination of fire resistance, moisture and mold protection, high strength, and environmental friendliness makes it a reliable choice for walls, floors, ceilings, SIPs, wet-area modules, and exterior facades.

By integrating MgO board into prefab modules, manufacturers can achieve:

-

Enhanced safety: Non-combustible panels provide fire protection for multi-story buildings and wet areas.

-

Structural stability: High compressive and flexural strength ensures dimensional stability during transport and assembly.

-

Efficient construction: Factory-ready panels reduce labor, minimize errors, and shorten assembly times.

-

Sustainability: Eco-friendly materials support LEED, BREEAM, and local green building certifications, while maintaining low VOC emissions.

-

Durability: Resistant to moisture, warping, mold, and UV exposure, MgO boards extend the life of modular homes.

Case studies from Europe, Australia, and the Middle East demonstrate that MgO board meets diverse environmental challenges while maintaining quality and safety standards. Whether used in SIPs, interior walls, floors, ceilings, or wet-area modules, MgO board enhances the overall performance and value of prefabricated houses.

As the global demand for modular housing grows, MgO board is poised to become an increasingly popular material choice for manufacturers seeking to deliver safe, sustainable, and efficient prefab homes. Its versatility, reliability, and ease of use make it a key component in the future of modern construction.

Learn how to properly install MgO boards for walls, ceilings, and flooring. This step-by-step guide covers cutting, fastening, joint treatment, etc.

Discover how MgO board performs in bathrooms and kitchens. Learn about moisture resistance, fire safety, mold prevention, and installation practices.

Learn how to use Magnesium Oxide (MgO) board for roofing. Explore types, installation steps, advantages, and precautions for durable, fire-resistant roofs.