Table of Contents

Ask Us Any Question

Introduction

Heat resistant boards have become increasingly popular in modern construction, especially in commercial and industrial projects where safety and durability are paramount. Known for their ability to withstand high temperatures and reduce fire risks, these boards are often marketed as a superior alternative to traditional materials like gypsum boards.

However, while heat resistant boards offer clear advantages, they are not without limitations. Understanding these potential drawbacks before making a purchase is crucial for contractors, architects, and building owners alike. From material performance constraints to installation challenges and cost considerations, there are several factors that could influence the effectiveness and practicality of using heat resistant boards in your project.

This article will explore the key limitations you must know before buying a heat resistant board, helping you make an informed decision and avoid costly mistakes.

Material Limitations

While heat resistant boards are engineered to withstand high temperatures, they do have certain material-related limitations that buyers need to understand.

Heat Resistance Thresholds

Not all heat resistant boards perform the same under extreme conditions. Each board has a specified temperature limit, and exceeding this threshold can compromise structural integrity. For example, prolonged exposure to temperatures beyond the board’s rated capacity may cause warping, cracking, or discoloration. Contractors should always check the manufacturer’s technical specifications and ensure the board is suitable for the intended application.

Moisture and Water Sensitivity

Another important consideration is how these boards react to moisture. Some heat resistant boards can absorb water if exposed to high humidity or direct contact, leading to swelling or reduced strength. This is especially relevant for projects in areas prone to moisture or where boards are used in kitchens, bathrooms, or near HVAC systems. Proper sealing, waterproof coatings, or using moisture-resistant variants can mitigate this risk.

Compatibility with Other Materials

Heat resistant boards may not always be compatible with every adhesive, coating, or decorative finish. Certain paints, tiles, or laminates may fail to adhere properly, or the board may react chemically with specific materials, affecting durability and appearance. Before finalizing installation, it is advisable to test compatibility on a small sample or consult the manufacturer for recommended material pairings.

Understanding these material limitations is essential to ensure the board performs as expected. Ignoring these factors can lead to costly repairs, shortened lifespan, and safety issues, which defeats the main purpose of using a heat resistant board in the first place.

Installation Challenges

Even the best heat resistant boards can pose difficulties during installation. These challenges often catch buyers off guard, especially if they assume that installation is similar to ordinary wall or ceiling panels.

Cutting and Handling Difficulties

Heat resistant boards are generally denser and harder than traditional gypsum boards. While this contributes to their durability and fire resistance, it also makes cutting and shaping them more challenging. Specialized tools such as carbide-tipped saw blades or heavy-duty cutters may be required, and improper handling can easily cause chipping, cracking, or even injury. Additionally, the boards are often heavier, requiring careful lifting and support during placement, particularly for ceiling or elevated wall installations.

Labor and Time Considerations

Due to their weight and hardness, installing heat resistant boards can be more labor-intensive than other materials. Projects may require additional manpower or longer installation times, which can increase labor costs. Inexperienced installers might struggle with proper alignment, securing boards without damage, or ensuring tight joints, leading to gaps or weak spots that compromise fire resistance. Planning for adequate time and skilled labor is essential to achieve a safe and professional result.

Understanding these installation challenges before purchasing helps prevent frustration, delays, and unexpected costs. It also ensures that the heat resistant board performs effectively once installed, providing the fire protection and durability you expect.

Cost Considerations

One of the key limitations of heat resistant boards is their cost. Compared to traditional materials, heat resistant boards often come with a higher price tag. This can impact both small and large-scale projects, especially when multiple boards are required.

While the upfront cost may seem significant, it is important to weigh it against the potential benefits. Heat resistant boards offer improved fire protection, durability, and often reduced maintenance costs over time. However, for budget-conscious projects or those with tight margins, the initial investment can be a deciding factor.

Additionally, higher material costs are sometimes compounded by installation expenses. As discussed earlier, these boards may require specialized tools and more skilled labor, further increasing the overall project budget. Buyers should calculate both material and installation costs to determine the true financial impact.

Understanding these cost considerations helps project managers and contractors make informed decisions. It also prevents unpleasant surprises during procurement or construction phases. While heat resistant boards are an excellent choice for safety and long-term performance, being aware of their financial implications is essential for successful project planning.

Maintenance and Durability Concerns

While heat resistant boards are designed to withstand high temperatures and provide fire protection, they are not completely maintenance-free. Understanding their long-term durability and upkeep requirements is essential for maximizing their performance.

Cracks and Deformation

Over time, heat resistant boards may develop minor cracks or slight warping, particularly in areas subject to fluctuating temperatures or structural movement. These issues, if left unaddressed, can compromise the board’s protective properties and the overall integrity of the installation. Regular inspections are recommended, especially in commercial kitchens, industrial facilities, or other high-heat environments.

Surface Wear and Damage

The surfaces of heat resistant boards can be prone to scratches, dents, or staining, particularly during cleaning or renovation work. Choosing appropriate cleaning methods and avoiding abrasive tools helps maintain the board’s appearance and longevity. In some cases, surface coatings or paints recommended by the manufacturer can enhance resistance to wear and tear.

Replacement and Repairs

Although durable, heat resistant boards may require replacement or repair after several years, depending on environmental conditions and usage intensity. Planning for potential maintenance costs ensures that your investment continues to provide safety and functionality without unexpected disruptions.

By understanding these maintenance and durability concerns, building owners and contractors can implement proper care routines. This ensures that heat resistant boards continue to offer reliable protection while maintaining their aesthetic appeal over time.

Regulatory and Safety Notes

When purchasing and installing heat resistant boards, it is essential to consider local regulations and safety standards. Compliance with building codes and fire safety requirements ensures that your project remains both legal and safe.

Building Codes and Standards

Different countries and regions have specific standards regarding fire-resistant materials. Heat resistant boards must meet these requirements to be used in commercial, industrial, or residential constructions. For example, some standards dictate the minimum fire-resistance rating, thickness, or installation method. Failing to comply can lead to inspection issues, fines, or safety hazards.

Fire Safety Compliance

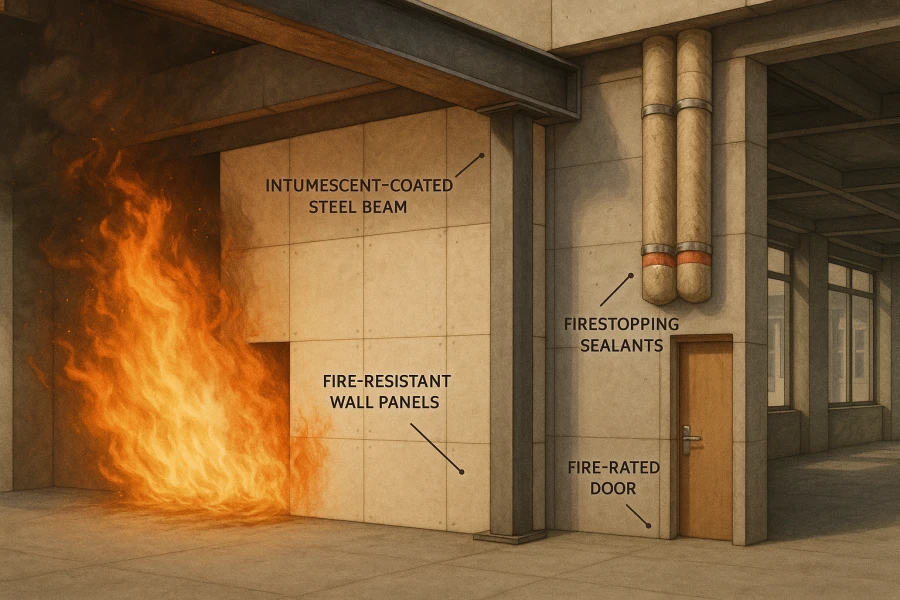

Even though heat resistant boards are designed to resist fire, their effectiveness depends on proper installation and adherence to safety guidelines. Gaps, improper joints, or incompatible materials can reduce fire resistance. Always follow manufacturer instructions and local fire regulations to ensure optimal protection.

Environmental and Health Considerations

Some boards may contain additives or coatings to enhance heat resistance. It is important to verify that these materials meet environmental and health safety standards, particularly in residential or high-occupancy buildings. Choosing certified, non-toxic boards can prevent potential health risks and environmental concerns. For instance, magnesium oxide boards are often recognized as a safe and eco-friendly option when properly manufactured, offering both fire resistance and health assurance.

By paying attention to regulatory and safety notes, buyers can avoid legal issues and ensure that heat resistant boards provide maximum protection. Compliance with standards is not only a legal requirement but also a key factor in safeguarding lives and property.

Conclusion

Heat resistant boards offer essential fire protection and durability, but they are not without limitations. From material constraints and installation challenges to higher costs, maintenance needs, and regulatory requirements, buyers must carefully evaluate whether these boards are the right choice for their specific projects.

Being aware of potential drawbacks helps contractors, architects, and building owners make informed decisions. Proper planning, skilled installation, and adherence to safety standards ensure that heat resistant boards perform effectively, providing long-term protection and peace of mind.

If you are considering using heat resistant boards and want expert guidance, feel free to contact us for professional advice or request sample boards. Our team can help you choose the right solution for your project, ensuring safety, compliance, and optimal performance.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

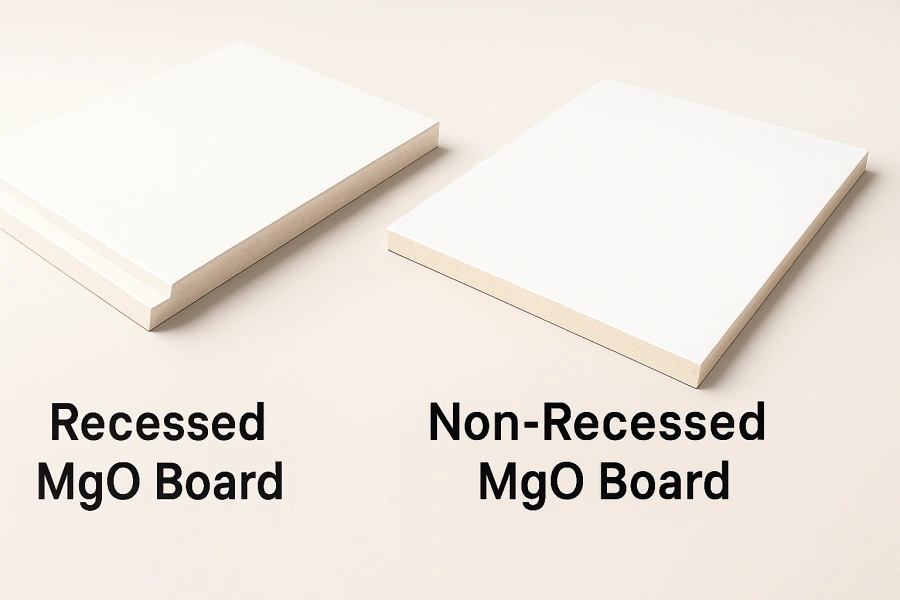

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.