Table of Contents

Ask Us Any Question

Introduction

In the modern construction industry, selecting the right building materials is more important than ever. Among the many options available, magnesium oxide (MGO) boards have emerged as a popular choice due to their fire resistance, durability, and eco-friendly properties. However, not all MGO boards are created equal. Choosing the wrong board can lead to increased costs, safety risks, and long-term maintenance problems.

This guide aims to help builders, contractors, and project planners avoid common mistakes when selecting best MGO boards. By understanding what makes a board high-quality and cost-effective, you can ensure a safer, more efficient, and sustainable construction project. Throughout this article, we will explore the criteria for selecting the best MGO board, highlight top suppliers in 2026, and provide practical tips for saving costs without compromising quality.

What is an MGO Board?

Magnesium oxide boards, commonly known as MGO boards, are a type of building material made primarily from magnesium oxide and other mineral compounds. These boards are designed to provide superior fire resistance, moisture resistance, and structural strength, making them suitable for a wide range of construction applications. Best MGO boards are increasingly preferred over traditional gypsum or plywood panels due to their durability and environmentally friendly properties.

Definition of Magnesium Oxide Board

An MGO board is essentially a panel composed of magnesium oxide, magnesium sulfate, and reinforcing materials such as fiberglass mesh. Unlike traditional gypsum boards, MGO boards are resistant to fire, water, and mold, and they do not release harmful chemicals into the environment. This makes them a safer and more sustainable choice for both residential and commercial construction projects.

Common Applications

Best MGO boards can be used in a variety of construction scenarios. They are commonly applied in:

-

Interior and exterior walls

-

Flooring underlayment

-

Roof and ceiling sheathing

-

Fire-rated doors and partitions

Their versatility allows architects and builders to use the same material for multiple purposes, reducing the complexity of sourcing different panels for different functions.

Key Benefits

The key benefits of best MGO boards include:

-

Fire resistance, often rated Class A or A1, which can prevent the spread of flames in buildings

-

Moisture and mold resistance, making them suitable for bathrooms, kitchens, and basements

-

Structural strength that allows for load-bearing applications

-

Eco-friendly composition, which contributes to green building standards

By understanding these fundamental characteristics, it becomes easier to evaluate and select the best MGO board for any project.

Common Mistakes When Choosing Best MGO Boards

Selecting the best MGO board can be challenging, especially with the wide variety of products available on the market. Many builders and project managers make avoidable mistakes that can impact the performance, durability, and cost-effectiveness of their projects. Understanding these common errors is the first step toward making an informed decision.

Ignoring Density and Thickness Requirements

One of the most frequent mistakes is overlooking the density and thickness specifications of MGO boards. These factors directly affect the board’s strength, fire resistance, and suitability for different applications. For instance, a board that is too thin may warp under moisture exposure, while a board with insufficient density may fail to provide the required structural support. Always check the technical datasheets and ensure the board meets the project’s specific requirements.

Overlooking Fire Resistance Ratings

Fire safety is a critical consideration, yet some buyers fail to verify the fire resistance rating of MGO boards. Not all boards offer the same level of protection. Choosing a board with a lower fire rating can compromise the safety of a building and may not comply with local fire safety regulations. Ensure that the board has certified fire ratings appropriate for your application.

Choosing Low-Quality Suppliers or Uncertified Products

Another common error is purchasing boards from suppliers without proper certifications or a proven track record. Low-quality boards may contain impurities, inconsistent formulas, or poor reinforcement, leading to cracking, warping, or reduced fire resistance. Always select reputable suppliers and confirm that the products have necessary certifications such as ISO, CE, or ASTM.

Focusing Only on Price, Not Long-Term Value

While it is tempting to prioritize upfront cost, focusing solely on price can be costly in the long term. Low-priced boards may lead to higher maintenance, replacement costs, and potential safety issues. Evaluating the total value—including durability, performance, and supplier reliability—ensures you choose a board that delivers long-term benefits and reduces overall project expenses.

How to Identify the Best MGO Board

After understanding the common mistakes in selecting best MGO boards, the next step is to know how to identify the highest quality options. The best MGO board is not necessarily the most expensive, but it must meet specific standards for performance, safety, and sustainability. Here are the key factors to consider.

Checking Certifications and Quality Standards

One of the most reliable ways to determine board quality is to verify certifications. Look for international standards such as ISO, CE, or ASTM. These certifications indicate that the product has passed rigorous testing for fire resistance, moisture protection, and structural integrity. Certified boards also ensure compliance with building codes, reducing the risk of project delays or legal issues.

Assessing Durability and Strength

The board’s physical properties, including density, thickness, and reinforcing materials, play a critical role in durability. Best MGO board should resist cracking, warping, and impact damage over time. Testing a sample board or reviewing the supplier’s technical data sheets can help ensure the material meets the structural requirements for your specific project.

Considering Environmental Impact and Sustainability

Sustainability is an increasingly important factor in modern construction. The best MGO boards use eco-friendly materials that do not release harmful chemicals. They are recyclable and contribute to green building certifications. Choosing environmentally responsible boards not only benefits the planet but also enhances the overall reputation and compliance of your construction project.

Evaluating Supplier Reliability and Support

Even the best MGO board is only as good as the supplier behind it. Reliable suppliers offer consistent quality, timely delivery, and professional technical support. They provide detailed product documentation, samples, and advice for installation. When evaluating suppliers, consider their experience, reputation, and ability to meet your project timelines.

Top MGO Board Suppliers in 2026

In 2026, several leading suppliers provide high-quality MGO boards for different construction needs. While each supplier offers strong performance, there are differences in company scale, pricing, and flexibility.

Large International Brands

These companies have a well-established reputation and offer a wide range of products. Their boards are consistently high quality and come with extensive certifications. However, as large enterprises, their pricing tends to be higher, and they may have less flexibility in order customization or small-batch deliveries.

Suparna MgO Board

Suparna stands out for its flexibility and responsiveness. Suparna can accommodate smaller orders, customized sizes, and faster delivery schedules. This makes it particularly suitable for projects where adaptability and cost efficiency are priorities, without compromising on performance.

Tips to Save Costs Without Compromising Quality

Selecting the best MGO board does not mean overspending. With careful planning and informed decision-making, you can achieve high-quality results while keeping costs under control. Here are some practical strategies.

Order in Bulk to Reduce Unit Cost

Purchasing boards in larger quantities often allows you to negotiate lower prices per unit. Bulk orders also minimize the frequency of shipments, which can reduce logistics costs and ensure a steady supply for ongoing projects.

Combine MGO Board with Compatible Accessories

Using compatible installation accessories, such as protective gear, adhesives, or complementary panels, can prevent material waste and reduce repair costs. Ensuring that all components work seamlessly together helps maintain the integrity and longevity of the installation.

Plan Projects Carefully to Avoid Waste

Accurate measurements, layout planning, and coordination among team members are critical. Mistakes during cutting or installation can lead to wasted boards and increased expenses. Taking the time to plan and organize your project will save both material costs and labor hours.

Use Local Logistics Partners for Faster Shipping

Shipping costs and delays can significantly impact project budgets. Partnering with reliable local logistics providers ensures faster delivery times and reduces the risk of damage during transit. This approach also provides more flexibility for urgent orders or last-minute adjustments.

Conclusion

Choosing the best MGO board requires careful evaluation of quality, performance, and supplier reliability. By understanding the key factors such as fire resistance, durability, environmental impact, and certifications, builders and project managers can avoid common mistakes and ensure long-term success for their projects.

Among the top suppliers in 2026, Suparna MgO Board stands out for its advanced production methods, wide range of options, and consistent international quality standards. Their boards are suitable for a variety of applications, from residential walls and flooring to commercial fire-rated installations, making them a reliable choice for those seeking both performance and value.

By following the guidelines in this article, you can save costs without compromising on quality, choose the best MGO board for your needs, and ensure a safer and more sustainable construction project. For further assistance, sample requests, or technical consultation, feel free to contact Suparna MgO Board and explore the full range of their high-quality solutions.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

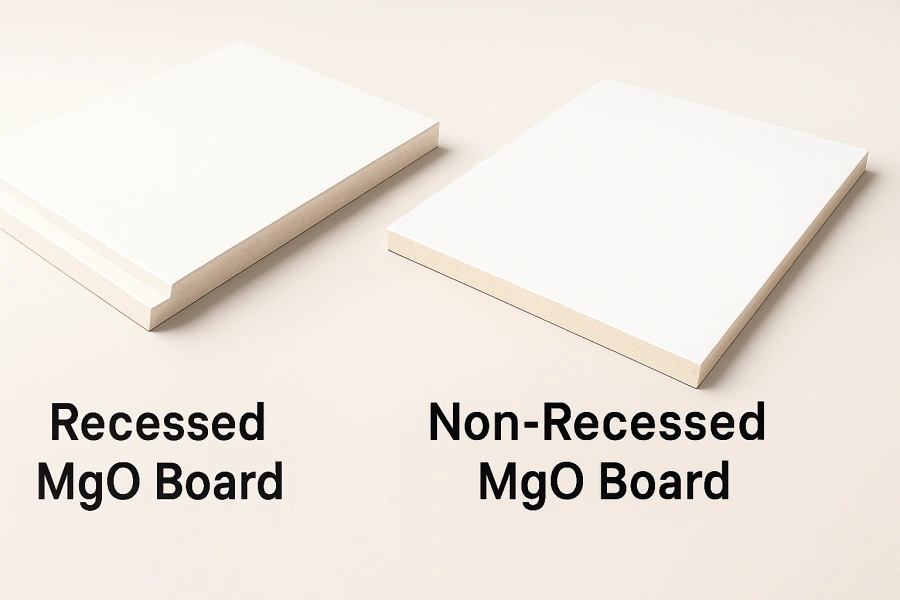

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

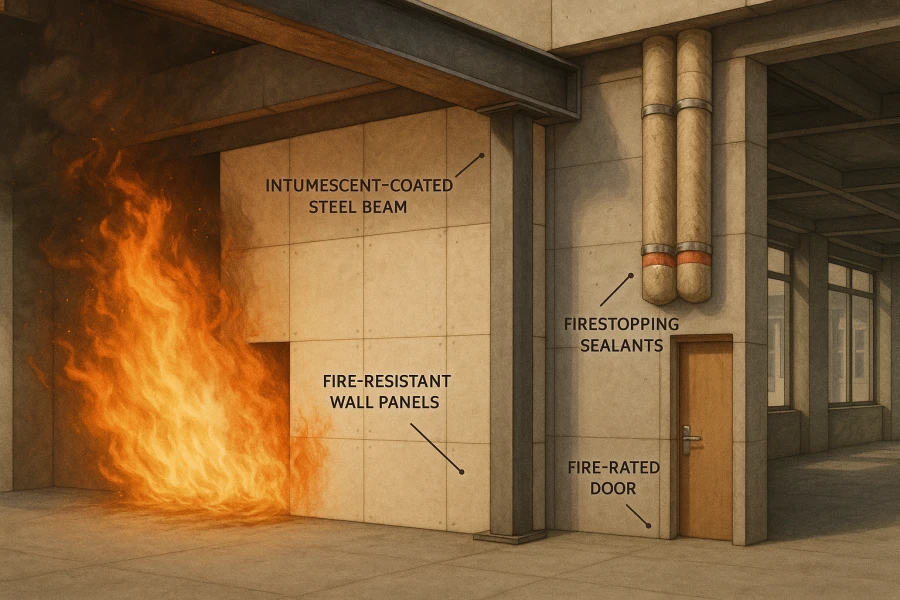

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.