Table of Contents

Ask Us Any Question

Introduction

Magnesium oxide boards (MgO boards) have become increasingly popular in modern construction due to their exceptional fire resistance, moisture resistance, and durability. Unlike traditional building materials such as gypsum or cement boards, MgO boards are non-toxic, eco-friendly, and offer superior structural stability.

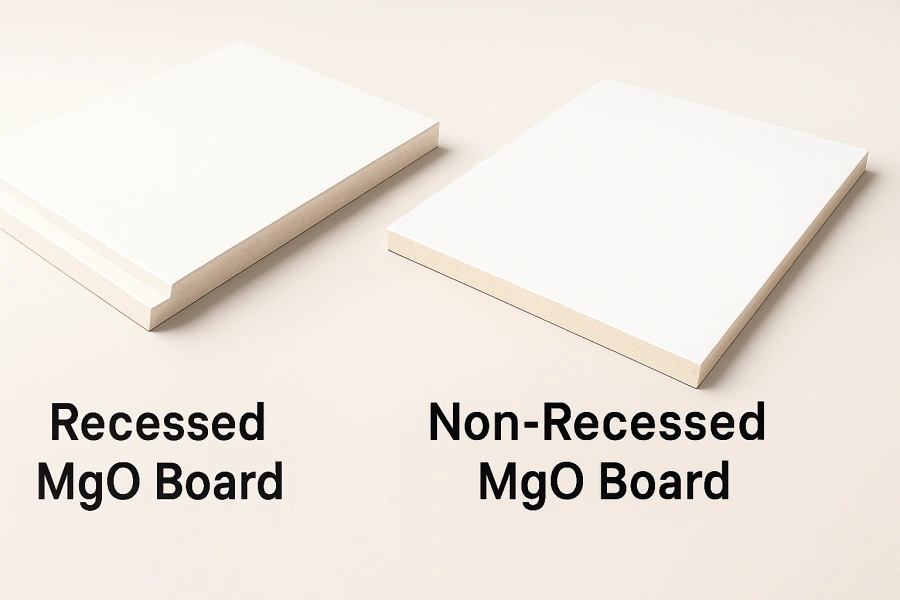

As more architects, contractors, and homeowners discover the benefits of MgO boards, choosing the right type for a project becomes crucial. One of the most common decisions is whether to use recessed MgO boards or non-recessed MgO boards. Each type has distinct features, advantages, and ideal applications.

This article will guide you through the differences between recessed and non-recessed MgO boards, explain what each type is best suited for, and help you make an informed decision for your construction or renovation project. By the end, you will have a clear understanding of how to select the right MgO board to meet both functional and aesthetic requirements.

What is an MgO Board?

A magnesium oxide board (MgO board) is a high-performance construction material made primarily from magnesium oxide, magnesium chloride or sulfate, and various fillers such as perlite or wood fibers. It is widely used as a fire-resistant, moisture-resistant, and eco-friendly alternative to traditional gypsum or cement boards.

MgO boards are valued for their unique combination of strength, durability, and safety. They are non-combustible, making them ideal for areas where fire protection is critical. Additionally, MgO boards are resistant to mold, mildew, and termites, which makes them suitable for both residential and commercial construction projects.

Key Features of MgO Boards

-

Fire Resistance: MgO boards can withstand high temperatures without igniting, providing enhanced safety for walls, ceilings, and partitions.

-

Moisture and Mold Resistance: Unlike gypsum boards, MgO boards perform well in humid environments such as bathrooms, kitchens, or basements.

-

Durability and Structural Strength: MgO boards are strong, impact-resistant, and less prone to warping or cracking over time.

-

Eco-Friendly and Non-Toxic: Made from natural minerals, MgO boards are safe for indoor use and do not release harmful chemicals.

Common Applications of MgO Boards

-

Walls, ceilings, and partitions in residential buildings

-

Offices, hotels, and commercial spaces requiring fire protection

-

Industrial facilities and functional areas where durability and moisture resistance are important

-

Renovation projects where a lightweight yet strong material is needed

By understanding what MgO boards are and their core benefits, you can better evaluate the differences between recessed and non-recessed types in the following sections.

What is a Recessed MgO Board?

A recessed MgO board is a type of magnesium oxide board with pre-formed grooves or recesses along its edges. These grooves are specifically designed to make joint finishing easier, allowing for a seamless and professional appearance once installed. Recessed MgO boards are popular in interior construction projects where aesthetics and a smooth finish are highly valued.

Features of Recessed MgO Boards

-

Pre-formed grooves: The recessed edges provide a natural space for joint compound or tape, making it easier to hide seams.

-

Smooth, seamless finish: After installation and finishing, the joints are nearly invisible, giving walls and ceilings a polished look.

-

Faster installation: Recessed edges reduce the time and labor required to achieve a smooth surface, especially for large-scale projects.

-

Professional appearance: Ideal for areas where a high-quality finish is required, such as offices, hotels, or luxury residential buildings.

Common Applications of Recessed MgO Boards

-

Interior walls and ceilings in residential and commercial buildings

-

High-end construction projects where aesthetics matter

-

Spaces requiring smooth, paint-ready surfaces for wallpaper, paint, or decorative panels

-

Environments where fire resistance is needed without compromising on appearance

Recessed MgO boards combine the inherent benefits of magnesium oxide—such as fire and moisture resistance—with a design that simplifies finishing, making them a preferred choice for projects that demand both performance and style.

What is a Non-Recessed MgO Board?

A non-recessed MgO board, also known as a flat or standard MgO board, has straight, flat edges without any pre-formed grooves. Unlike recessed boards, non-recessed MgO boards require additional joint treatment during installation to achieve a smooth, finished surface. Despite this, they retain all the core benefits of MgO boards, including fire resistance, moisture resistance, and structural durability.

Features of Non-Recessed MgO Boards

-

Flat, straight edges: Non-recessed boards do not have grooves, which allows for flexible installation methods.

-

Requires joint treatment: To create a seamless surface, additional joint compound, tape, or mesh must be applied at the seams.

-

Durable and strong: These boards maintain excellent fire and moisture resistance and are highly resistant to mold, warping, and termites.

-

Customizable finish: Non-recessed boards are suitable for projects where the installer wants more control over joint finishing and decorative treatments.

Common Applications of Non-Recessed MgO Boards

-

Partition walls and ceilings in residential, commercial, or industrial buildings

-

Functional areas where joint appearance is less critical

-

Renovation projects requiring custom finishing techniques

-

Structural or practical applications where aesthetics are secondary

Non-recessed MgO boards provide a versatile option for projects where flexibility in installation or custom finishing is important. While the finishing process may require more effort compared to recessed boards, they offer the same reliability and performance characteristics, making them suitable for a wide range of construction needs.

Key Differences Between Recessed and Non-Recessed MgO Boards

Although both recessed and non-recessed MgO boards share the core benefits of magnesium oxide—such as fire resistance, moisture resistance, and durability—they differ primarily in edge design, installation process, and finishing requirements. Understanding these differences is essential for choosing the right board for your project.

Comparison Table

| Feature | Recessed MgO Board | Non-Recessed MgO Board |

|---|---|---|

| Edge Type | Pre-formed grooves along edges | Flat, straight edges |

| Installation | Easier and faster; joints are hidden | Requires additional joint treatment |

| Finish | Smooth and seamless | Customizable but more labor-intensive |

| Labor Requirement | Less labor needed | More labor needed for finishing |

| Aesthetic Value | High; ideal for visible surfaces | Medium; suitable for functional areas |

| Common Use | Interior walls and ceilings, decorative areas | Partition walls, industrial or renovation projects |

Installation Differences

-

Recessed MgO Boards: The pre-formed grooves allow joint compound or tape to sit neatly within the edges, reducing finishing time and labor. This makes recessed boards ideal for projects that require a seamless, paint-ready surface.

-

Non-Recessed MgO Boards: Flat edges require extra joint treatment, often involving multiple layers of joint compound and sanding. While this adds installation time, it provides flexibility for custom finishes and decorative designs.

Cost and Labor Considerations

-

Recessed boards can save labor costs and installation time due to easier joint treatment.

-

Non-recessed boards may have a lower material cost but can require more labor to achieve a smooth finish, especially in high-visibility areas.

By comparing these features, contractors, architects, and DIY enthusiasts can quickly determine which type of MgO board best suits their project requirements, balancing cost, time, and aesthetics.

How to Choose Between Recessed and Non-Recessed MgO Boards

Choosing the right type of MgO board depends on several factors, including project type, aesthetic requirements, installation time, and budget. By understanding these considerations, you can make a well-informed decision that balances functionality, appearance, and cost.

Based on Project Type

-

Recessed MgO Boards: Best suited for interior walls and ceilings where a seamless, high-quality finish is required. Ideal for residential homes, offices, hotels, and commercial spaces where aesthetics are important.

-

Non-Recessed MgO Boards: Suitable for partition walls, industrial applications, or areas where joint appearance is less critical. They are also preferred for renovation projects requiring custom finishes.

Based on Finish Requirements

-

If you want a smooth, seamless surface that is ready for paint, wallpaper, or decorative panels, recessed MgO boards are the preferred choice.

-

If the project allows for custom joint treatment or decorative finishes, non-recessed boards provide flexibility and control over the final appearance.

Based on Installation Time and Cost

-

Recessed boards can save labor and installation time due to their pre-formed grooves, making them cost-effective for large projects.

-

Non-recessed boards may have a slightly lower material cost but require more labor for joint finishing, which could increase overall project time and expenses.

By evaluating these factors, you can select the right MgO board that meets your project’s functional, aesthetic, and budgetary needs.

Conclusion

Both recessed and non-recessed MgO boards offer the inherent advantages of magnesium oxide, including fire resistance, moisture resistance, durability, and eco-friendliness. The main difference lies in their edge design and installation process: recessed boards have pre-formed grooves that simplify joint treatment and provide a seamless, professional finish, while non-recessed boards have flat edges that offer flexibility for custom finishing but require more labor during installation.

When deciding between these two types, consider your project type, desired finish, and installation requirements. Recessed MgO boards are ideal for interior walls and ceilings where aesthetics are critical and time-saving installation is important. Non-recessed MgO boards are suitable for functional partitions, industrial applications, or projects where custom joint treatment and flexibility are preferred.

By understanding these differences, contractors, architects, and homeowners can make informed choices that ensure safety, durability, and a visually appealing result. Selecting the right MgO board not only improves the quality of construction but also maximizes efficiency and long-term performance.

Explore the best heat proof and heat resistant materials for safer construction. Learn their benefits, applications, and safety advantages.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

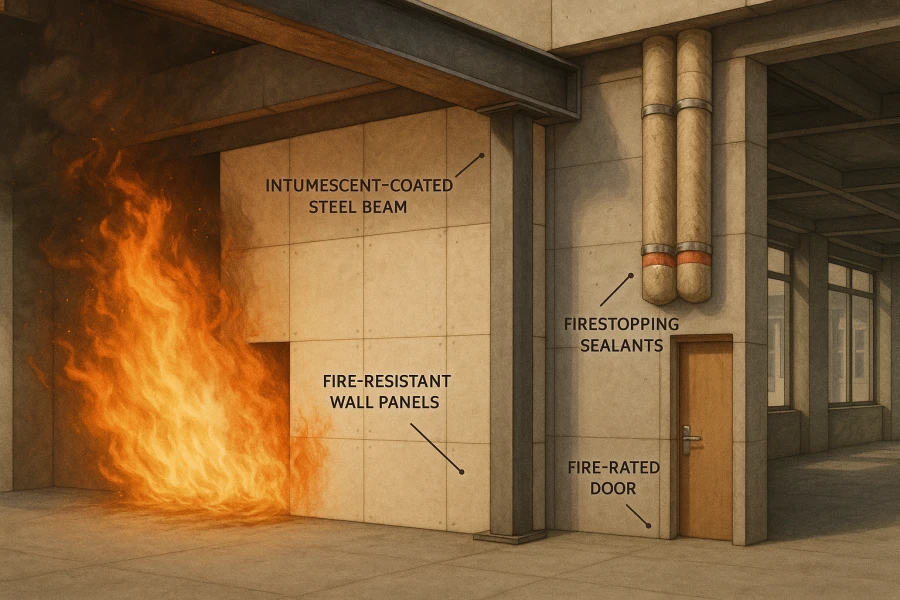

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.