Table of Contents

Ask Us Any Question

Why Magnesium Oxide Matters Today

Magnesium oxide, commonly known as MgO, has emerged as one of the most versatile and essential chemical compounds in modern industries. Its unique combination of chemical stability, high melting point, and environmental friendliness makes it a crucial material in construction, manufacturing, agriculture, and even medicine. With the increasing global demand for fire-resistant, durable, and eco-friendly materials, magnesium oxide is gaining prominence not only among industrial experts but also among businesses and consumers who seek reliable and sustainable solutions.

In recent years, the construction sector has particularly embraced magnesium oxide for its role in producing fireproof panels, wallboards, and insulation materials. At the same time, the chemical industry values MgO for its ability to react with various acids and water, forming essential compounds used in fertilizers, pharmaceuticals, and environmental applications. Understanding what magnesium oxide is and why it is widely used can help businesses, engineers, and consumers make informed decisions when choosing materials that meet both performance and safety standards.

This article explores the fundamentals of magnesium oxide, its key properties, diverse applications, global market presence, and where to source it, providing a comprehensive guide for anyone looking to leverage this remarkable compound.

What Is Magnesium Oxide (MgO)?

Magnesium oxide (MgO) is a white, hygroscopic solid mineral that occurs naturally as the mineral periclase and is also produced synthetically from magnesite or other magnesium-rich minerals. Chemically, it consists of one magnesium atom and one oxygen atom, giving it the chemical formula MgO. The compound is highly stable and exhibits remarkable resistance to heat and chemical reactions under normal conditions, making it suitable for a wide range of industrial applications.

The production of magnesium oxide typically involves the calcination of magnesium carbonate or magnesium hydroxide at high temperatures. This process removes water and carbon dioxide, leaving behind pure MgO. The resulting compound can then be crushed, ground, and graded to meet specific purity and particle size requirements for different industrial uses.

Magnesium oxide is distinct from other magnesium compounds such as magnesium chloride (MgCl₂) or magnesium sulfate (MgSO₄). Unlike MgCl₂, which is highly soluble in water, MgO has limited solubility and forms magnesium hydroxide (Mg(OH)₂) when it reacts with water. This property is particularly important in applications like cement, refractory materials, and environmental treatments. MgO’s high melting point, around 2852°C, and its ability to maintain structural integrity at elevated temperatures are key factors that make it a preferred choice for heat-resistant applications.

Overall, magnesium oxide is a fundamental chemical building block, valued for its versatility, durability, and safety, providing the foundation for numerous industrial, agricultural, and construction applications.

Key Properties and Technical Advantages of Magnesium Oxide

Magnesium oxide (MgO) stands out among chemical compounds due to its remarkable combination of physical, chemical, and environmental properties. Its unique characteristics make it highly versatile across various industries, from construction and manufacturing to agriculture and medicine. Understanding the key properties and technical advantages of magnesium oxide is essential for anyone seeking reliable, high-performance materials.

Chemical Stability and High Melting Point

One of the most notable features of magnesium oxide is its exceptional chemical stability. MgO is highly resistant to most chemical reactions under normal conditions, which makes it a durable and dependable material. Its high melting point of approximately 2852°C and boiling point near 3600°C allow MgO to maintain structural integrity even under extreme heat. This property makes it ideal for refractory applications, such as furnace linings, crucibles, and heating elements, where materials must withstand prolonged exposure to high temperatures without degrading.

Excellent Heat and Electrical Insulation

Magnesium oxide also exhibits excellent heat insulation properties while maintaining low thermal conductivity. This combination allows it to act as a protective barrier against heat transfer, making it valuable in thermal insulation systems. Additionally, MgO is widely used as an electrical insulator due to its ability to withstand high voltages without conducting electricity. Its stable dielectric properties enable safe and efficient operation in electrical and electronic components, including power cables, heating wires, and industrial insulation systems.

Reactivity and Versatility

While MgO is chemically stable, it retains selective reactivity that adds to its versatility. When it reacts with acids, magnesium oxide forms various magnesium salts, which are essential in fertilizers, pharmaceuticals, and water treatment processes. In contact with water, MgO converts into magnesium hydroxide (Mg(OH)₂), a reaction that is particularly important in the production of cement, plaster, and other construction materials. This controlled reactivity allows magnesium oxide to serve multiple roles across different industries without compromising safety or stability.

Environmental and Health Safety

Another significant advantage of magnesium oxide is its environmental and health-friendly nature. MgO is non-toxic, non-corrosive, and generally considered safe for handling in industrial, agricultural, and medical settings. It does not release harmful emissions, making it a sustainable choice for applications where environmental considerations are critical. The compound’s ability to be recycled and reused further enhances its appeal as an eco-friendly material, aligning with modern sustainability standards and green building initiatives.

Durability and Long-Term Reliability

Magnesium oxide offers long-term durability that few other compounds can match. It maintains its structural and chemical integrity over extended periods, resisting degradation from moisture, heat, and chemical exposure. This longevity ensures that products and structures incorporating MgO remain safe, stable, and functional for many years, reducing maintenance costs and enhancing overall efficiency.

In summary, magnesium oxide’s key properties—chemical stability, high melting point, thermal and electrical insulation, controlled reactivity, environmental safety, and long-term durability—make it a highly advantageous material. These technical benefits explain why MgO continues to be an essential compound in modern industries, providing reliable solutions for applications ranging from industrial manufacturing to sustainable construction and beyond.

Major Applications of Magnesium Oxide

Magnesium oxide (MgO) is an exceptionally versatile compound, with applications spanning construction, industrial manufacturing, agriculture, and medical fields. Its unique combination of chemical stability, heat resistance, and environmental safety allows it to perform critical functions in a wide range of products and processes. Understanding the major applications of magnesium oxide helps businesses and end-users select the right material for their specific needs.

Construction and Building Materials

In the construction sector, magnesium oxide plays a key role in producing fire-resistant and durable building materials. MgO is commonly used to manufacture magnesium oxide boards that offer superior fire resistance compared to traditional gypsum boards. Its ability to maintain structural integrity under high temperatures makes it ideal for fireproof walls and partitions. Additionally, magnesium oxide is used in flooring, ceiling boards, and insulation panels, providing moisture resistance, dimensional stability, and long-term durability. The versatility of MgO in construction has contributed to its rising popularity in modern green building projects, where sustainability and safety are prioritized.

Industrial and Manufacturing Uses

Magnesium oxide’s high melting point and chemical stability make it indispensable in industrial applications. It is used as a refractory material in furnaces, kilns, and crucibles to withstand extreme heat without degrading. In metallurgy, MgO serves as a flux, aiding in the smelting and refining of metals. The compound is also utilized as a raw material in ceramics, glass, and rubber manufacturing, where it enhances strength, thermal resistance, and durability. Furthermore, magnesium oxide is applied in chemical processes as a neutralizer for acids and as a catalyst in various industrial reactions, demonstrating its multifunctional utility.

Agriculture and Environmental Applications

MgO is valuable in agriculture due to its nutrient content and environmental benefits. It is a key component in magnesium fertilizers that improve soil quality and promote plant growth. Its alkaline properties help neutralize acidic soils, creating optimal conditions for crops. In environmental management, magnesium oxide is used to treat wastewater, neutralize acidic industrial effluents, and stabilize pollutants, preventing contamination and supporting sustainable practices. These applications highlight MgO’s ability to contribute to both productivity and environmental protection.

Medical and Pharmaceutical Uses

The medical and pharmaceutical industries also benefit from magnesium oxide’s properties. As a dietary supplement, MgO provides a source of magnesium for maintaining healthy bones, muscles, and metabolic functions. It is used as an antacid to relieve heartburn and indigestion and as a mild laxative to alleviate constipation. Its safety profile and non-toxic nature make it suitable for various formulations, reflecting its versatility beyond industrial and construction applications.

Other Specialized Applications

Beyond these major sectors, magnesium oxide finds use in other specialized areas. In electronics, MgO acts as an insulator and protective coating. It is employed in flame retardants, high-temperature insulation boards, and chemical stabilization of polymers. The compound also contributes to environmental remediation and advanced research applications, demonstrating that its utility extends far beyond conventional uses.

In conclusion, magnesium oxide’s wide-ranging applications—from construction and industrial manufacturing to agriculture and medicine—highlight its essential role in modern society. Its unique combination of heat resistance, chemical stability, and environmental safety allows it to meet diverse industrial, commercial, and scientific needs, making MgO a truly indispensable compound across multiple domains.

Grades and Forms of MgO in the Market

Magnesium oxide (MgO) is available in a variety of grades and forms, each tailored for specific industrial, agricultural, construction, or medical applications. Understanding the differences between these grades and forms is essential for selecting the right type of magnesium oxide for a particular use, ensuring optimal performance and cost-efficiency.

Grades of Magnesium Oxide

Magnesium oxide is generally classified into three main grades based on its calcination temperature, purity, and reactivity:

-

Light-Burned MgO (Caustic Calcined)

-

Produced at relatively low temperatures (700–1000°C).

-

Highly reactive with water, forming magnesium hydroxide quickly.

-

Commonly used in agriculture as a soil amendment, in water treatment, and as a raw material for chemical reactions.

-

-

Hard-Burned MgO

-

Calcined at moderate temperatures (1000–1500°C).

-

Moderately reactive; retains structural stability while still participating in chemical processes.

-

Suitable for applications in refractory bricks, cement production, and some construction materials where controlled reactivity is needed.

-

-

Dead-Burned MgO

-

Produced at very high temperatures (over 1500°C).

-

Highly stable, with low reactivity and minimal hydration.

-

Used in high-temperature refractory applications, steelmaking, and other industrial processes where durability under extreme heat is critical.

-

Each grade has specific advantages depending on the application, so selecting the correct MgO grade ensures maximum efficiency and performance.

Forms of Magnesium Oxide

Magnesium oxide is available in several physical forms, allowing it to be used across a wide range of industries:

-

Powder

-

The most common form, easy to transport and mix with other compounds.

-

Used in construction (e.g., cement, plaster), agriculture (fertilizers), and industrial chemical processes.

-

-

Granules

-

Larger particle size than powder, often used in refractory applications or slow-reacting chemical processes.

-

Preferred when controlled dissolution or reaction rate is required.

-

-

Pellets or Briquettes

-

Compressed forms for easier handling in large-scale industrial applications.

-

Typically used in metallurgy, water treatment, and high-temperature furnaces.

-

-

Sheets or Boards

-

Pre-formed panels made from MgO, often used in construction for fireproofing, wallboards, and flooring.

-

While technically a derivative of magnesium oxide, these products leverage the same chemical properties of MgO for practical applications.

-

Choosing the Right Grade and Form

Selecting the right grade and form of magnesium oxide requires consideration of the intended application, required reactivity, durability, and handling preferences. Light-burned MgO is ideal for rapid chemical reactions, while dead-burned MgO is necessary for extreme heat and refractory stability. Similarly, powder is suitable for mixing and formulation, whereas pellets or boards are better for bulk handling or construction purposes. Understanding these distinctions ensures that magnesium oxide delivers its full potential in any application.

In summary, magnesium oxide’s versatility is enhanced by the availability of multiple grades and forms. By carefully choosing the appropriate type, users can achieve superior performance in chemical reactions, industrial processes, agricultural applications, and construction projects, making MgO a highly adaptable and valuable material across industries.

Where to Buy Magnesium Oxide?

Magnesium oxide (MgO) is widely produced and traded globally, with a significant portion of supply originating from China. As the largest producer of magnesium oxide, China has developed advanced production facilities, especially concentrated in the northeastern provinces. These regions have decades of experience in MgO production, ensuring consistent quality, high output, and competitive pricing. For buyers around the world, sourcing magnesium oxide from China provides access to a stable supply of high-purity material suitable for a wide range of applications.

In addition to China, magnesium oxide is produced in smaller quantities in countries such as Russia, Turkey, and the United States. However, these regions primarily serve local or niche markets, and the majority of industrial-grade magnesium oxide still comes from Chinese manufacturers. This global distribution makes China the most reliable hub for purchasing magnesium oxide in bulk or for specialized applications.

When considering where to buy MgO, it is essential to focus on suppliers with verified quality control, proper certification, and experience in exporting. Buyers should pay attention to the purity level, particle size, and burn grade (light-burned, hard-burned, or dead-burned), depending on their specific requirements. Additionally, logistics, packaging, and transportation options should be considered to ensure the material arrives safely and efficiently.

For international buyers, sourcing magnesium oxide from China offers the dual advantage of experienced production and global shipping capabilities. By connecting with reputable suppliers, businesses can secure high-quality MgO suitable for construction, industrial, agricultural, or pharmaceutical uses.

Finally, for readers seeking a trusted supplier with reliable quality and experience in magnesium oxide production, it is advisable to reach out to professional manufacturers who can provide samples, detailed specifications, and guidance on the most suitable MgO grade for their needs. This approach ensures that every purchase delivers the performance, stability, and versatility that magnesium oxide is known for.

Global Market Outlook for Magnesium Oxide

The global demand for magnesium oxide (MgO) has been steadily increasing due to its versatile applications in construction, industry, agriculture, and healthcare. Analysts predict that this trend will continue over the next decade, driven by growing interest in fire-resistant building materials, environmentally friendly manufacturing processes, and sustainable agricultural practices.

Construction Industry Driving Demand

In the construction sector, magnesium oxide is increasingly used in fireproof panels, wallboards, flooring, and insulation materials. With stricter building safety regulations and the rising emphasis on green construction, MgO has become a preferred choice over traditional gypsum or cement-based materials. As a result, construction projects in North America, Europe, and Asia are contributing significantly to the global demand for high-quality magnesium oxide.

Industrial and Manufacturing Applications

Industrial manufacturing also plays a major role in shaping the market. MgO is essential in refractory products, steelmaking, cement production, ceramics, and chemical processing. The need for durable, high-temperature-resistant, and chemically stable materials ensures consistent industrial demand. Regions with large metallurgical and manufacturing sectors, such as China, India, and Europe, represent significant consumption hubs for industrial-grade magnesium oxide.

Agricultural and Environmental Growth

Magnesium oxide is increasingly valued in agriculture for soil conditioning, magnesium supplementation, and environmental protection applications. As the global population grows, sustainable farming practices are gaining importance, boosting demand for MgO fertilizers and soil amendments. Additionally, its use in wastewater treatment and environmental remediation highlights the compound’s expanding role in sustainable practices, further supporting market growth.

Regional Market Insights

-

China: As the world’s largest producer, China dominates both domestic consumption and exports, particularly from the northeastern provinces where production is highly concentrated.

-

Europe and North America: These regions rely on imports for high-purity MgO used in construction and specialized industrial applications.

-

Middle East and Southeast Asia: Growing infrastructure projects and industrial development are increasing regional consumption.

Future Trends and Opportunities

The magnesium oxide market is expected to experience steady growth due to ongoing industrialization, urbanization, and the adoption of green construction standards. Technological innovations in production, including improved calcination processes and higher-purity grades, are likely to enhance the performance and efficiency of MgO, attracting new applications and industries.

In conclusion, magnesium oxide’s market outlook is highly positive. Its versatility, durability, and environmentally friendly characteristics position it as a critical material across multiple sectors. Global demand is projected to continue rising, particularly in construction, industrial, agricultural, and environmental applications, offering ample opportunities for manufacturers, distributors, and buyers worldwide.

Building a Safer Future with MgO

Magnesium oxide (MgO) is more than just a chemical compound; it is a versatile material that underpins modern construction, industrial processes, agriculture, and healthcare. Its exceptional chemical stability, high melting point, thermal and electrical insulation properties, and environmental safety make it an indispensable resource across multiple sectors. From fireproof building panels to industrial refractories, from soil amendments to pharmaceutical supplements, MgO continues to demonstrate its unmatched versatility and reliability.

As industries around the world prioritize sustainability, safety, and efficiency, the role of magnesium oxide becomes even more significant. Its environmentally friendly nature, combined with long-term durability, allows businesses and consumers to implement solutions that are both practical and responsible. Furthermore, the availability of various grades and forms ensures that magnesium oxide can be tailored to meet the specific needs of diverse applications, whether in construction, manufacturing, agriculture, or healthcare.

For businesses and professionals seeking to source high-quality magnesium oxide, understanding the compound’s properties, grades, and applications is crucial. China remains the primary global hub for MgO production, offering consistent quality and large-scale supply, particularly from its northeastern provinces with decades of production experience. By connecting with experienced suppliers, buyers can secure magnesium oxide that meets international standards and fulfills their operational requirements.

If you are interested in exploring premium magnesium oxide products, requesting samples, or obtaining detailed technical specifications, contacting an experienced manufacturer can provide valuable guidance. By choosing the right supplier, you ensure that your projects or products benefit from the full advantages of magnesium oxide, achieving both performance and safety goals.

Magnesium oxide is not just a material—it is a pathway to safer, more sustainable, and more efficient solutions across industries. Now is the time to leverage its potential for your next project.

Discover what an MgO board is made of, including its core binder, activators, fillers, and reinforcement. Learn key raw materials and components.

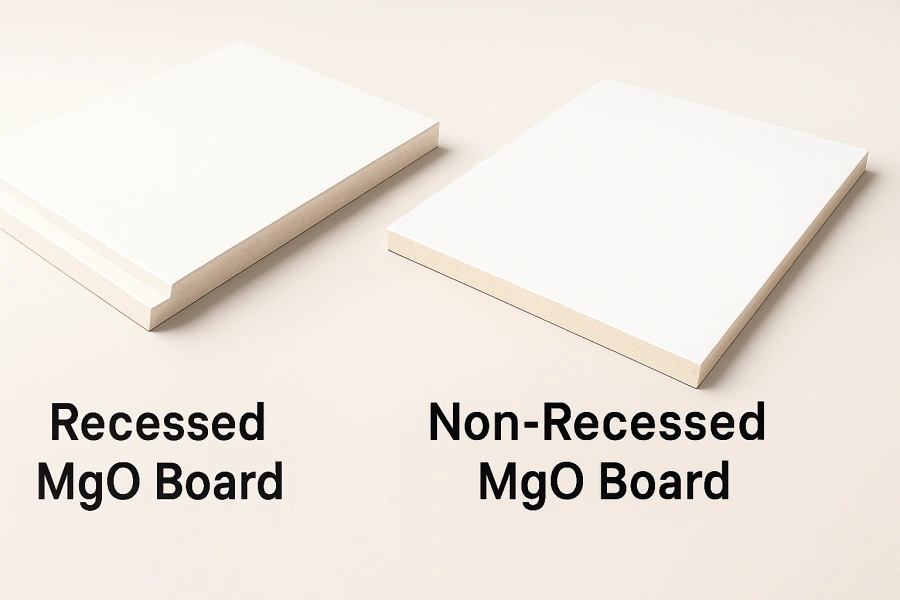

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

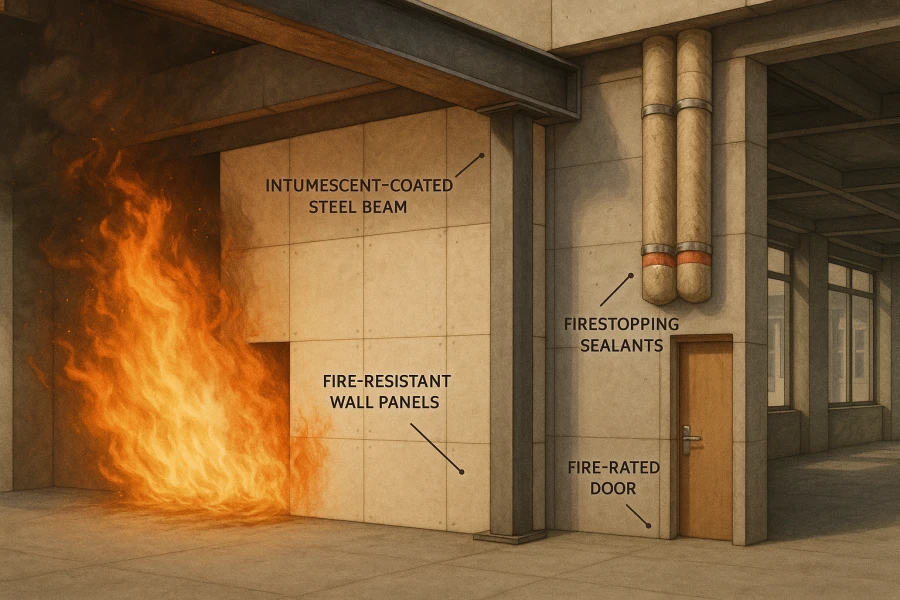

Passive fire protection materials slow fire spread, protect structures, and save lives. Learn about 5 effective materials for safer, compliant buildings.