Table of Contents

Ask Us Any Question

1. Introduction to Fire Rated Subfloors

What is a fire rated subfloor?

A fire rated subfloor is a type of flooring foundation specifically designed to resist fire and slow its spread in case of an emergency. Unlike standard subfloors made from plywood or OSB, fire rated subfloors are constructed using materials that meet stringent fire safety standards. These fire rated subfloors are commonly used in residential, commercial, and industrial buildings where safety codes require enhanced fire resistance.

Fire rated subfloors are not only designed to withstand high temperatures but also to provide structural support, ensuring that the overall flooring system remains stable during a fire. They are often tested according to international standards such as ASTM E119 or EN 13501 to verify their fire-resistance performance. Using a fire rated subfloor can significantly reduce the risk of fire damage, protect the lives of occupants, and minimize property loss.

Why fire resistance matters in subfloor construction

Fire resistance is a critical factor in subfloor construction because the subfloor serves as the foundation of the entire flooring system. If a standard subfloor catches fire easily, it can accelerate the spread of flames throughout the building. This can compromise structural integrity, endanger occupants, and increase insurance costs.

A fire rated subfloor ensures that in the event of a fire, the flooring can resist heat for a certain period, giving occupants more time to evacuate and firefighters a better chance to contain the blaze. Moreover, fire resistant subfloors often exhibit additional benefits such as moisture resistance, mold prevention, and long-term durability, making them a more reliable investment for both safety and performance.

In modern construction, fire safety regulations increasingly require buildings to include fire rated subfloors, especially in multi-story residential or commercial projects. Choosing the right material for a fire rated subfloor is essential to meet these regulations and to enhance overall building resilience.

2. Common Subfloor Materials

Before selecting the ideal subfloor for a project, it is important to understand the most commonly used materials and how they perform in terms of fire resistance, durability, and overall practicality. Each material has unique characteristics that make it suitable for certain applications while presenting limitations in other areas. Below, we explore four widely used subfloor materials.

Plywood Subfloor

Overview:

Plywood has long been a standard choice for subfloor construction due to its strength and versatility. Made from layers of wood veneer bonded together with adhesives, plywood offers good structural integrity and can support various types of floor finishes.

Pros:

-

Strong and stable, capable of handling heavy loads

-

Relatively affordable and widely available

-

Easy to cut and install, saving time on labor

Cons:

-

Highly flammable and offers limited fire resistance

-

Sensitive to moisture, which can cause warping or delamination over time

Plywood subfloors are often used in residential construction where cost is a primary concern, but they may require additional fireproofing treatments to meet modern safety codes.

Oriented Strand Board (OSB) Subfloor

Overview:

Oriented Strand Board (OSB) is made from compressed wood strands and adhesives, forming a dense, structural panel. OSB has gained popularity as an alternative to plywood due to its cost-effectiveness and uniformity.

Pros:

-

Excellent structural rigidity, suitable for supporting flooring systems

-

More affordable than high-grade plywood

-

Consistent thickness and fewer voids than traditional plywood

Cons:

-

Absorbs water more easily, leading to swelling or degradation if exposed to moisture

-

Fire resistance is generally lower than mineral-based boards like MgO

OSB is commonly chosen for budget-conscious projects but may require fire-resistant coatings or underlayments in areas with strict safety requirements.

Magnesium Oxide (MgO) Board Subfloor

Overview:

Magnesium Oxide (MgO) board is a mineral-based material known for its excellent fire resistance and durability. It is widely used in projects where fire safety, moisture resistance, and long-term performance are critical.

Pros:

-

Superior fire resistance, often rated for up to one hour or more

-

Resistant to mold, mildew, and moisture

-

Highly durable and dimensionally stable over time

Cons:

-

Higher material cost compared to wood-based subfloors

MgO boards are ideal for commercial or multi-story residential projects, particularly where fire safety codes are stringent and longevity is a priority.

Cement Board Subfloor

Overview:

Cement boards are composed of cement and reinforcing fibers, providing a solid, fireproof base. They are commonly used under tile, stone, or other finishes that require a rigid, moisture-resistant foundation.

Pros:

-

Completely fireproof and highly moisture resistant

-

Durable and long-lasting, with minimal maintenance

-

Ideal for high-traffic or wet areas such as bathrooms and kitchens

Cons:

-

Heavy and labor-intensive to install

-

Can be brittle if not supported properly, requiring careful handling

Cement boards are often selected for applications where both fire and water resistance are crucial, although the weight and installation effort can increase project complexity.

3. Performance Comparison

Selecting the right subfloor material requires a careful evaluation of its performance characteristics. While each material has distinct strengths, understanding their differences can help builders and homeowners make informed decisions. Here, we compare plywood, OSB, MgO board, and cement board across key criteria.

Fire Resistance Ratings

Fire resistance is the most critical factor for a fire rated subfloor.

-

Plywood: Low fire resistance; untreated plywood ignites easily and burns quickly. Additional fire-retardant treatments are often necessary to meet building codes.

-

OSB: Slightly better than plywood but still flammable; fire-retardant coatings can improve performance.

-

MgO Board: Excellent fire resistance; typically rated for up to 1–2 hours of fire exposure, depending on thickness. Mineral-based composition prevents flame spread.

-

Cement Board: Non-combustible; provides the highest level of fire resistance and does not contribute to smoke or toxic fumes during a fire.

Choosing MgO or cement boards ensures compliance with stringent fire safety standards, making them ideal for high-risk areas.

Moisture and Mold Resistance

Moisture management affects the longevity and safety of the flooring system.

-

Plywood: Susceptible to warping, delamination, and mold growth when exposed to moisture.

-

OSB: Absorbs water more readily than plywood, which can cause swelling and structural weakening.

-

MgO Board: Highly resistant to moisture and mold due to its mineral composition; ideal for humid environments.

-

Cement Board: Completely water-resistant; does not support mold growth and maintains dimensional stability even in wet conditions.

MgO and cement boards are the preferred choice for areas with high humidity or risk of water exposure.

Durability and Lifespan

Durability determines how long the subfloor can perform without significant maintenance.

-

Plywood: Moderate lifespan; vulnerable to moisture and fire, requiring regular inspection and potential replacement.

-

OSB: Similar to plywood but slightly less durable if exposed to moisture.

-

MgO Board: Long-lasting and highly stable; resistant to cracking, shrinkage, and deformation over time.

-

Cement Board: Extremely durable; maintains integrity under heavy loads and in high-traffic areas, though care must be taken during installation to prevent cracking.

For projects prioritizing longevity, MgO and cement boards clearly outperform wood-based subfloors.

Cost-Effectiveness and Maintenance

Cost and ease of maintenance are practical considerations for every construction project.

-

Plywood: Low initial cost, but additional fireproofing and potential moisture mitigation can increase total expenses.

-

OSB: Affordable and consistent in quality, though additional treatments may be needed for fire or moisture protection.

-

MgO Board: Higher upfront cost, but long-term benefits such as fire safety, durability, and minimal maintenance can offset the initial investment.

-

Cement Board: Higher installation costs due to weight and labor, yet offers long-term savings in durability and low maintenance requirements.

Investing in fire rated subfloors like MgO or cement boards often proves cost-effective over the building’s lifecycle, balancing upfront costs with safety and longevity.

4. How to Choose the Right Subfloor Material

Selecting the most suitable subfloor material depends on multiple factors, including project type, local building codes, budget, and installation requirements. A thoughtful decision ensures both safety and long-term performance of the flooring system.

Project Type and Local Building Codes

The type of project—residential, commercial, or industrial—plays a key role in choosing a subfloor. Multi-story buildings and commercial spaces often require stricter fire-resistance ratings, making MgO board or cement board a preferred choice.

Local building codes may dictate minimum fire ratings or specific subfloor materials for safety compliance. For example, some jurisdictions require mineral-based boards in multi-unit dwellings to reduce fire hazards. Understanding and adhering to these regulations is essential to avoid costly modifications or penalties during inspection.

Budget vs. Performance Considerations

While plywood and OSB offer lower upfront costs, their limited fire resistance and susceptibility to moisture can lead to higher maintenance expenses over time.

MgO board and cement board have higher initial costs, but their superior fire resistance, moisture protection, and long-term durability often provide better value in the long run. Evaluating the total cost over the life of the building—rather than just material prices—ensures an investment that prioritizes both safety and quality.

Installation and Labor Factors

Ease of installation is another important consideration. Plywood and OSB are lightweight and easier to cut, making them suitable for projects with limited labor resources.

MgO boards require careful handling and precise installation techniques to prevent cracking and ensure proper alignment, while cement boards are heavy and labor-intensive but provide unmatched fire and water resistance. Choosing a material that matches available labor skills and installation equipment can prevent delays and maintain construction quality.

By balancing project requirements, budget constraints, and installation capabilities, builders can make informed decisions about the optimal fire rated subfloor material. For most projects emphasizing safety and long-term performance, MgO board and cement board emerge as strong candidates.

5. Conclusion and Recommendation

Selecting the right fire rated subfloor is a crucial decision for any construction project. Through this guide, we have explored the top four subfloor materials—plywood, OSB, MgO board, and cement board—highlighting their respective advantages and limitations.

Plywood and OSB offer affordability and ease of installation but fall short in fire resistance and long-term durability. Cement board provides unmatched fireproofing and moisture resistance but is heavier and more labor-intensive to install. Among the options, magnesium oxide (MgO) board stands out for its combination of excellent fire resistance, mold and moisture resistance, and structural stability. Although the initial cost is higher, the long-term benefits make it a wise investment for both safety and performance.

When choosing a subfloor, it is essential to consider your project type, budget, local building codes, and installation resources. Prioritizing fire safety and durability ensures not only compliance with regulations but also peace of mind for building occupants.

For builders, architects, and homeowners looking for reliable fire rated subfloor solutions, we provide expert consultation and high-quality materials tailored to your project needs. Contact our team today to explore how our MgO boards can enhance safety and longevity in your construction projects.

Explore the best heat proof and heat resistant materials for safer construction. Learn their benefits, applications, and safety advantages.

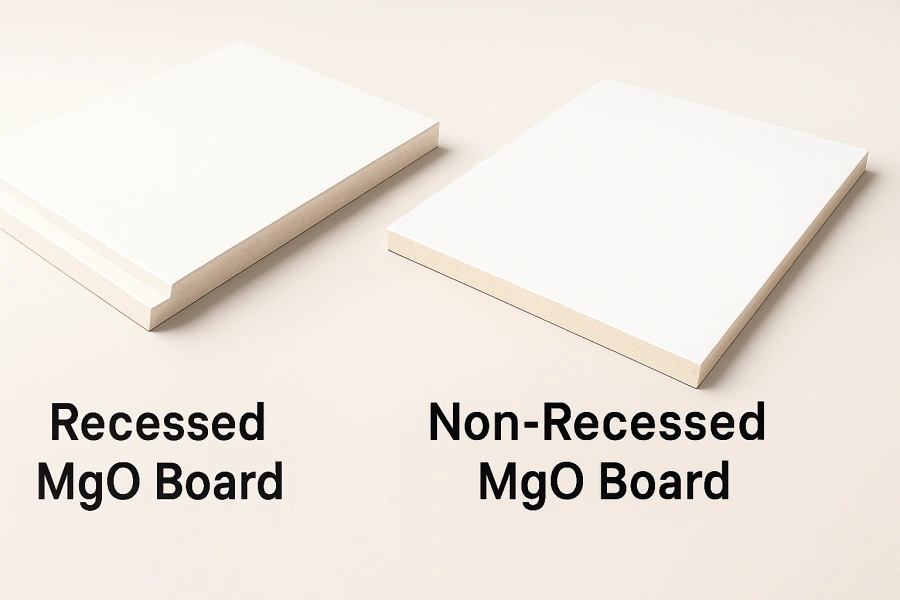

Compare recessed vs non-recessed MgO boards. Learn features, applications, and tips to choose the right fire- and moisture-resistant board.

Compare MgSO4 board vs MgCl2 board: discover key differences, performance, and durability to choose the best mgo board for your project.