Table of Contents

Introduction

When we talk about fireproof and eco-friendly construction materials, MGO board—short for magnesium oxide board—often stands out. But what is MGO board made of, exactly? Understanding its composition is key to appreciating why it performs so well in modern buildings.

An MGO board is not a single substance but a carefully engineered combination of mineral binders, fillers, and reinforcing materials. Each ingredient contributes a specific property—some improve strength, some reduce weight, and others enhance moisture or fire resistance. Knowing what goes into the board also helps builders select the right type for their project, whether it’s chloride-based or sulfate-based.

In this article, we’ll break down the seven essential ingredients that make up an MGO board and explain how each one contributes to its remarkable durability, safety, and performance.

Core Binder — Magnesium Oxide (MgO)

At the heart of every magnesium oxide board lies magnesium oxide (MgO)—the primary binder that gives the board its strength and fireproof quality. MgO is a mineral compound derived from calcined magnesite, a naturally occurring form of magnesium carbonate. When mixed with an activator and water, it undergoes a chemical reaction that forms strong magnesium oxychloride or magnesium oxysulfate cement, depending on the formula used.

The result is a solid, stable structure with exceptional fire resistance, compressive strength, and dimensional stability. Unlike gypsum, which loses strength when exposed to high temperatures, MgO maintains its integrity even under extreme heat. This is why MGO boards are widely used in fire-rated wall systems, ceilings, flooring, and sheathing panels.

Beyond performance, magnesium oxide is also an eco-friendly material. It’s non-toxic, contains no asbestos or formaldehyde, and emits no VOCs. Its mineral origin makes it naturally resistant to mold, insects, and moisture, further extending the service life of buildings where it’s used.

Activator — Magnesium Chloride (MgCl₂)

While magnesium oxide acts as the main binder, it needs an activator to trigger the hardening reaction. In most traditional MGO boards, this activator is magnesium chloride (MgCl₂). When combined with MgO and water, it forms a cementitious compound called magnesium oxychloride cement (MOC)—a material known for its impressive fire resistance, quick curing, and smooth surface finish.

Magnesium chloride helps the mixture set firmly and gives the board excellent adhesion and dimensional stability. Boards using MgCl₂ are widely used in interior partitions, ceilings, and subfloor systems due to their balance of strength and workability. However, this chloride-based system comes with a potential risk if not properly treated.

Corrosion Risk if Not Treated

One critical issue in some low-quality MGO boards is efflorescence. This happens when unreacted chloride ions inside the board migrate to the surface and crystallize as the board absorbs moisture from the air. Visually, this appears as a white powdery substance or surface dampness.

More importantly, the chloride ions can also react with metal fasteners, screws, or steel structures in contact with the board, leading to corrosion over time. This can compromise the stability and safety of the entire system if left unchecked.

To prevent such problems, responsible manufacturers—like Suparna—apply a soaking process after initial curing. This process removes excess chloride ions from the board before drying, effectively reducing the risk of efflorescence and metal corrosion. In addition, the use of high-purity raw materials, proper curing conditions, and waterproof coatings further ensures long-term stability and reliability.

In short, magnesium chloride is an essential ingredient in traditional MGO boards, but it must be handled with care. When produced under strict quality control and treated correctly, MgCl₂-based boards can perform safely and durably for decades.

Alternative Activator — Magnesium Sulfate (MgSO₄)

For projects where metal corrosion or efflorescence is a concern, magnesium sulfate (MgSO₄) serves as a safer alternative to magnesium chloride. When used as the activator in an MGO board, MgSO₄ reacts with magnesium oxide to form magnesium oxysulfate cement (MOS), a chloride-free binder system.

Unlike MgCl₂-based boards, MgSO₄ boards do not suffer from efflorescence, and there is no risk of chloride-induced corrosion of embedded metals. This means there’s no need for a soaking or washing process, simplifying manufacturing and installation while enhancing long-term safety.

It’s important to note that MgCl₂ and MgSO₄ systems are mutually exclusive—a board cannot contain both. Manufacturers choose one activator based on the intended application: MgCl₂ is often preferred for interiors due to fast curing and smooth finish, while MgSO₄ is ideal where metal contact or moisture exposure could pose problems.

In addition to safety, MgSO₄-based boards maintain excellent fire resistance, mechanical strength, and dimensional stability, comparable to chloride-based boards. For architects, builders, and engineers, choosing MgSO₄ boards can be a more reliable, low-maintenance option, particularly in commercial or industrial environments.

👉️ Check the differences between MgSO4 board and MgCl2 board

Filler — Sawdust (Wood Fiber)

Sawdust, or wood fiber, is a key filler in many MGO boards. Its primary role is to enhance toughness and reduce brittleness, making the board easier to handle, cut, and screw without cracking. By introducing natural fibers into the mineral matrix, manufacturers improve the board’s flexural strength and impact resistance.

Beyond mechanical benefits, sawdust contributes to acoustic insulation by dampening sound transmission through walls and ceilings. It also slightly reduces the board’s density, which makes installation easier and reduces transportation costs.

From a sustainability perspective, using sawdust—often sourced from recycled wood or sawmill by-products—makes MGO boards more environmentally friendly. This aligns with green building standards and helps architects meet eco-certifications without compromising performance.

In summary, sawdust is a simple yet effective ingredient that balances strength, flexibility, and sustainability in modern MGO boards.

Lightweight Aggregate — Perlite

Perlite, a naturally occurring volcanic glass, is widely used as a lightweight aggregate in MGO boards. Its primary function is to reduce the overall density of the board while maintaining sufficient structural strength. This makes panels easier to handle and install, especially in ceilings, partitions, and flooring applications.

In addition to lowering weight, perlite contributes significantly to thermal insulation. Its porous structure traps air, helping to maintain stable indoor temperatures and improving the energy efficiency of buildings. It also enhances fire resistance, as perlite can withstand high temperatures without degrading, complementing the board’s magnesium oxide core.

Perlite’s inclusion ensures that MGO boards remain strong yet lightweight, combining practicality with safety. Builders benefit from panels that are easy to transport, cut, and install without compromising durability or fireproof performance.

Reinforcement — Fiberglass Mesh

Fiberglass mesh is an essential reinforcement layer embedded within MGO boards to improve tensile strength and resistance to cracking. While the magnesium oxide core provides compressive strength, fiberglass ensures that the board can withstand bending, impact, and installation stresses without fracturing.

Typically, the mesh is placed in strategic layers during the board’s manufacturing process, creating a composite structure where the fibers distribute stress evenly. This reinforcement is especially important for large panels or subfloor applications, where unsupported areas might otherwise crack over time.

Beyond strength, fiberglass mesh also contributes to the board’s dimensional stability, preventing warping or deformation in humid environments. Its inclusion makes MGO boards more durable and reliable, suitable for both residential and commercial construction projects.

Surface Layer — Non-woven Fabric

The final ingredient in many MGO boards is non-woven fabric, which serves as a surface layer to enhance board performance and finish quality. This fabric improves surface flatness, ensuring a smooth and even panel that is ready for painting, laminates, or other decorative finishes.

Non-woven fabric also enhances bonding between the core and surface coatings, reducing the risk of delamination or peeling over time. In addition, it helps protect the board during handling and installation, acting as a buffer against minor scratches and impacts.

For builders and designers, non-woven fabric provides practical benefits: it makes the board easier to install, improves adhesion of finishing materials, and contributes to a cleaner, professional appearance in the completed structure.

Manufacturing Snapshot — How These Ingredients Become a Board

Creating an MGO board is a precise process that transforms magnesium oxide, activators, fillers, reinforcements, and surface layers into a durable, fireproof panel. Here’s a simplified overview of the production steps:

-

Proportioning and Mixing

-

Magnesium oxide is combined with the chosen activator—either magnesium chloride or magnesium sulfate.

-

Sawdust, perlite, and other fillers are added to balance strength, flexibility, and weight.

-

Water is introduced to initiate the chemical reaction, and the mixture is thoroughly blended to ensure uniform consistency.

-

-

Forming and Layering

-

The mixture is poured into molds or formed into sheets.

-

Fiberglass mesh is embedded during this stage to provide tensile reinforcement.

-

Non-woven fabric is applied to the surface for finish quality and adhesion support.

-

-

Pressing and Cutting

-

Boards are pressed under controlled pressure to achieve uniform density and thickness.

-

Panels are cut to standard sizes, with attention to maintaining smooth edges and precise dimensions.

-

-

Curing and Post-treatment

-

Boards undergo a controlled curing process to allow the chemical reaction to complete.

-

For MgCl₂-based boards, a soaking step may be applied to remove excess chloride ions and prevent efflorescence or corrosion.

-

-

Drying and Finishing

-

The boards are dried to reach optimal moisture content.

-

Surface finishing and quality inspection ensure the final product meets fire resistance, strength, and dimensional stability standards.

-

Through this careful combination of ingredients and controlled manufacturing steps, the final MGO board achieves a balance of strength, fire resistance, moisture stability, and environmental friendliness, making it suitable for a wide range of construction applications.

👉️ Check the entire production process

Composition Impact — Performance, Safety & Best Practices

Each ingredient in an MGO board plays a distinct role, and together they create a high-performance, safe, and durable construction material. Understanding these contributions helps builders, architects, and engineers make informed choices.

-

Magnesium Oxide (MgO): Provides the board’s core strength, fire resistance, and long-term stability.

-

Magnesium Chloride (MgCl₂): Enables rapid setting and adhesion but requires proper soaking to prevent efflorescence and corrosion when metal fasteners are used.

-

Magnesium Sulfate (MgSO₄): Safer alternative activator, no soaking needed, ideal for metal-contact or humid environments.

-

Sawdust (Wood Fiber): Improves flexibility, impact resistance, and contributes to acoustic performance.

-

Perlite: Reduces weight and enhances thermal insulation and fire resistance.

-

Fiberglass Mesh: Provides tensile reinforcement, preventing cracks and improving board durability.

-

Non-woven Fabric: Enhances surface flatness, bonding, and handling protection.

Best Practices:

-

Choose MgSO₄-based boards for applications near steel or metal components to eliminate corrosion risk.

-

Verify whether MgCl₂ boards have undergone proper soaking treatment.

-

Ensure proper screw spacing and panel support when using sawdust-filled boards to maintain strength.

-

Consider perlite and fiber content depending on desired weight, insulation, and structural performance.

By selecting boards with the appropriate composition and handling them correctly, builders can maximize performance, safety, and longevity, while minimizing maintenance and potential hazards.

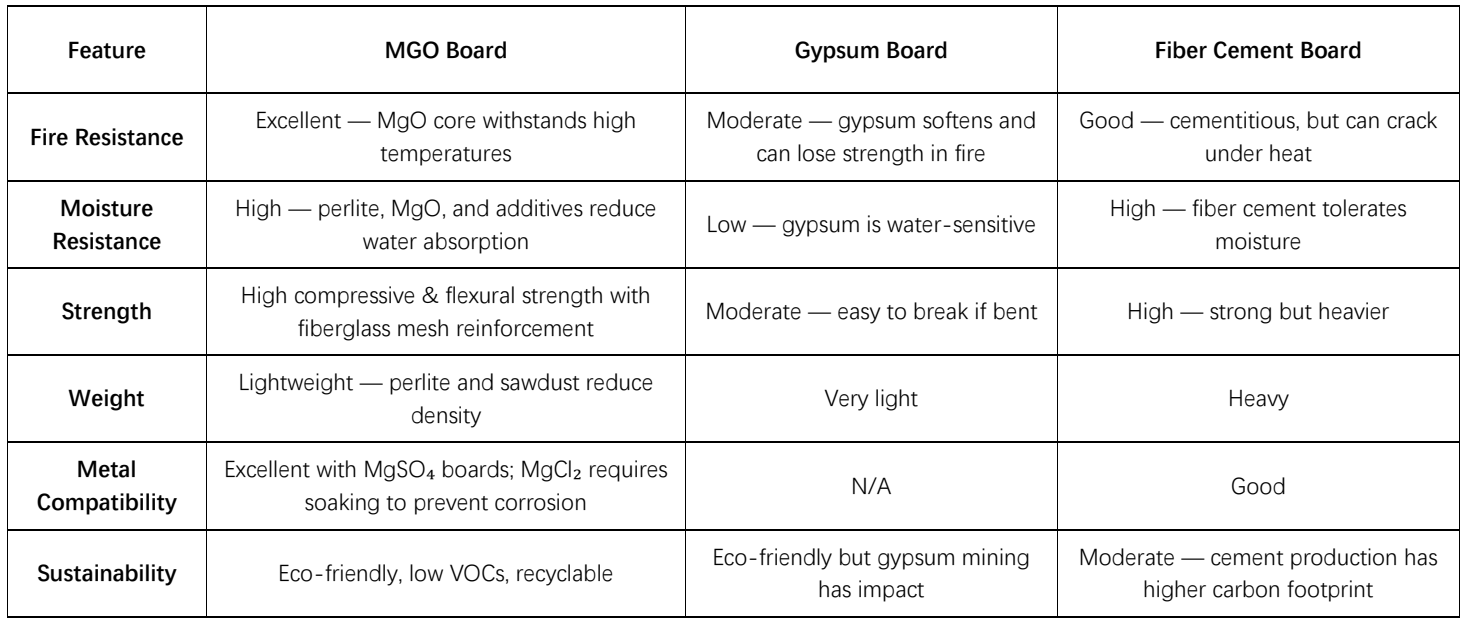

Quick Comparison — MgO Board vs Gypsum & Fiber Cement

MGO boards stand out when compared to traditional wall and ceiling materials such as gypsum board and fiber cement board. Here’s a concise comparison highlighting the impact of composition:

This comparison shows that MGO boards, due to their carefully engineered composition, offer a balanced combination of fire safety, moisture resistance, strength, and environmental benefits, making them a preferred choice in modern construction.

Conclusion

In summary, understanding what an MGO board is made of reveals why it is a superior choice for modern construction. The seven key ingredients—magnesium oxide, magnesium chloride or sulfate, sawdust, perlite, fiberglass mesh, and non-woven fabric—work together to provide:

-

Fire resistance and structural integrity

-

Moisture stability and metal compatibility

-

Lightweight yet strong performance

-

Eco-friendly and sustainable benefits

By carefully selecting the type of activator and verifying manufacturing quality, builders can ensure maximum safety, durability, and long-term performance.

At Suparna, we combine these high-quality ingredients with precise manufacturing techniques to produce MGO boards that meet international standards and diverse construction needs.

Interested in learning more or requesting a sample? Contact us today and discover how our MGO boards can elevate your next project—safer, stronger, and environmentally responsible.

Discover why MGO building material is the future-proof green solution for durable, fire-resistant, and eco-friendly construction projects.

Discover why MGO board USA is the smart choice for American construction—fire-resistant, durable, eco-friendly, and compliant with US building standards.

Discover the current MGO board price per m² in 2025. Learn factors affecting cost, compare with fiber cement boards, and get tips to save on your project.