build your dream home

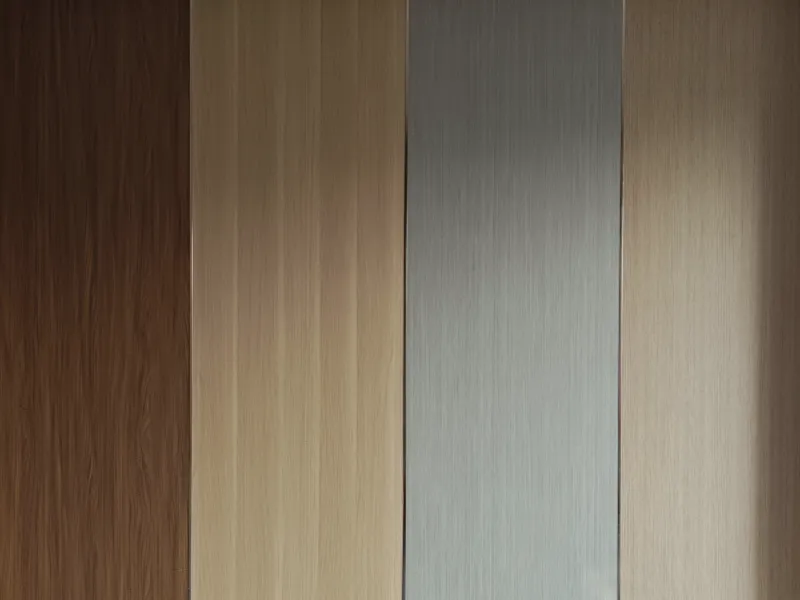

Suparna Magnesium Oxide Board

At Suparna, we offer a full range of high-performance Magnesium Oxide Boards (MgO board)designed for diverse construction needs. Our product line includes MgO wall boards, mgo flooring boards, mgo door panels, highway tunnel boards, and decorative mgo boards—each engineered to meet specific requirements.

Features of Suparna Magnesium Oxide Board

Suparna MgO board combines fire safety, moisture resistance, and environmental friendliness with durability and ease of installation. It’s the smart solution for high-performance, sustainable building projects.

Fireproof A1

Rated A1 for top-level fire resistance, the board can withstand open flames for at least two hours in wall assemblies.

Moisture Resistant

Moisture resistant and mold-resistant, it performs well in humid environments like bathrooms and kitchens.

Green & Healthy

Completely free from asbestos, formaldehyde, and harmful chemicals. Produces no smoke or odor when exposed to fire.

Easy Construction

Lightweight for easy transport and fast installation. Can be cut, nailed, or screwed using standard construction tools.

Ultra-Durable

Extremely resistant to corrosion, acid, and alkali. Maintains structural strength and form even after many decades.

Sound Insulation

Efficiently reduces outside noise pollution. Its dense, uniform core also absorbs indoor echoes and vibrations.

Applications of Suparna Magnesium Oxide Board

Suparna MgO board is a smart choice for various construction needs, offering a perfect combination of safety, durability, and performance.

Suparna MgO Board vs Other Fireproof Boards

Compared to calcium silicate board, fiber cement board, and gypsum board, Suparna magnesium oxide board delivers superior performance in fire and moisture resistance, with added benefits of non-toxicity and ease of installation.

😀 Excellent / Good 😐 Average / Fair ☹️ Poor / Needs Improvement

| Property | Magnesium Oxide Board | Calcium Silicate Board | Fiber Cement Board | Gypsum Board |

|---|---|---|---|---|

| Fire Resistance | 😀 | 😀 | 😀 | ☹️ |

| Moisture Resistance | 😀 | 😐 | 😐 | ☹️ |

| Physical Properties | 😀 | 😐 | 😀 | ☹️ |

| Ease of Installation | 😀 | ☹️ | 😐 | 😀 |

| Toxicity / Safety | 😀 | 😀 | 😐 | 😐 |

| Environmental Impact | 😀 | 😐 | ☹️ | ☹️ |

| Cost (Relative) | 😐 | ☹️ | 😐 | 😀 |

📌 Summary:

- Magnesium Oxide Board offers the best balance of fire resistance, moisture performance, workability, and environmental safety.

- Calcium Silicate Board is excellent for fire and mold, but can be brittle and harder to process.

- Fiber Cement Board is strong but heavy, dusty when cut, and may not be eco-friendly.

- Gypsum Board is cheap and easy to install, but weak in moisture and fire resistance.

Global Applications of Suparna Magnesium Oxide Board

Suparna MgO Board has been widely adopted in high-profile commercial, public, and residential projects around the world, such as Yanqi Lake International Convention & Exhibition Center, Sunrise Kempinski Hotel, Tencent Headquarters.

Magnesium Oxide Board FAQs

Here you’ll find answers to the most frequently asked questions about our magnesium oxide board, including its specifications, packaging, and applications.